Vapor condensing and recovering device

A technology for condensation recovery and water vapor, which is applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of inability to guarantee crude oil coils, increase labor intensity of employees, and increase the frequency of water replenishment, and achieve reasonable structure and high recovery rate High, reduce the effect of adding water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

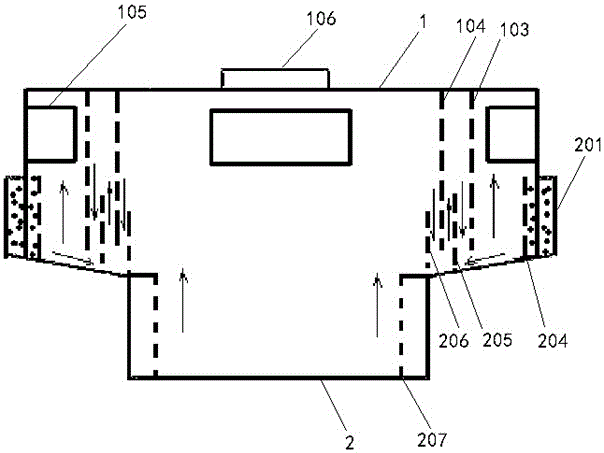

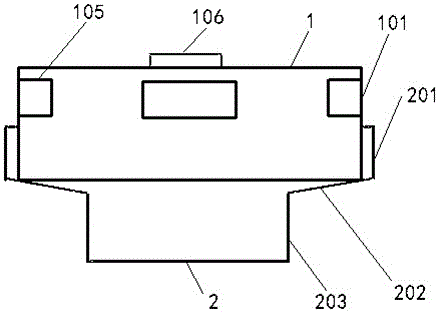

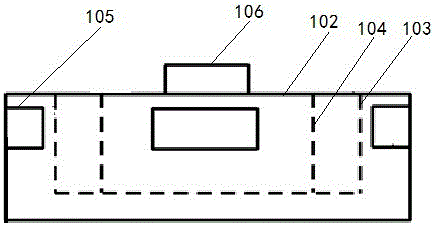

[0025] A water vapor condensation recovery device, comprising an upper cover 1 and a lower cover 2, such as image 3 with Figure 4 As shown, the upper cover 1 includes a cylindrical body 101, one end of the cylindrical body 101 is open, and the other end is sealed by the top plate 102, and the cylindrical body 101 is provided with welding on the top plate 102 and coaxial with the cylindrical body 101. The upper-level annular plate 103 and the upper secondary annular plate 104, the upper secondary annular plate 104 is located in the upper-level annular plate 103; as Figure 5 with Image 6 As shown, the lower cover 2 includes an outer ring annular plate 201, a truncated circular plate 202, and a bottom annular plate 203. One end of the small diameter of 202 is connected with the end of the bottom annular plate 203, and the lower cover 2 is provided with a lower secondary annular plate 204, a lower third-level annular plate 205 and a lower fourth-level annular plate 206 in se...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 As shown, the space between the outer annular plate 201 and the lower secondary annular plate 204 is filled with water. The water vapor turns back multiple times in the water vapor condensation recovery device, and the water vapor in the device is condensed into water droplets under the cooling effect of the water between the outer annular plate 201 and the next secondary annular plate 204 and the external flowing air, And recycling, at the same time, the water between the outer annular plate 201 and the lower secondary annular plate 204 can ensure a good seal when the upper cover 1 and the lower cover 2 are embedded.

Embodiment 3

[0032] On the basis of Embodiment 1, in order to facilitate the flow of water droplets into the water inlet, the bottom ends of the lower secondary annular plate 204, the lower third-stage annular plate 205 and the lower fourth-stage annular plate 206 are in contact with the inner surface of the cone-shaped annular plate 202 There are multiple holes everywhere. Specifically, the water vapor turns back multiple times in the water vapor condensation recovery device, and under the cooling effect of the external flowing air, the water vapor in the device is condensed into water droplets, and flows into the water inlet from the hole for recycling and saving water resources, and reduce the number of staff replenishing water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com