Dredging equipment and sewage circulation control system, control method and device thereof

A sewage circulation and hydraulic control system technology, applied in the field of sanitation machinery, can solve the problems of increasing the cleaning frequency of clean water tanks, high maintenance costs, and the system's inability to self-adaptively adjust the water output, so as to reduce the number of times of water addition and sludge transfer, which is practical Improvement of performance and economy, realizing the effect of continuous operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

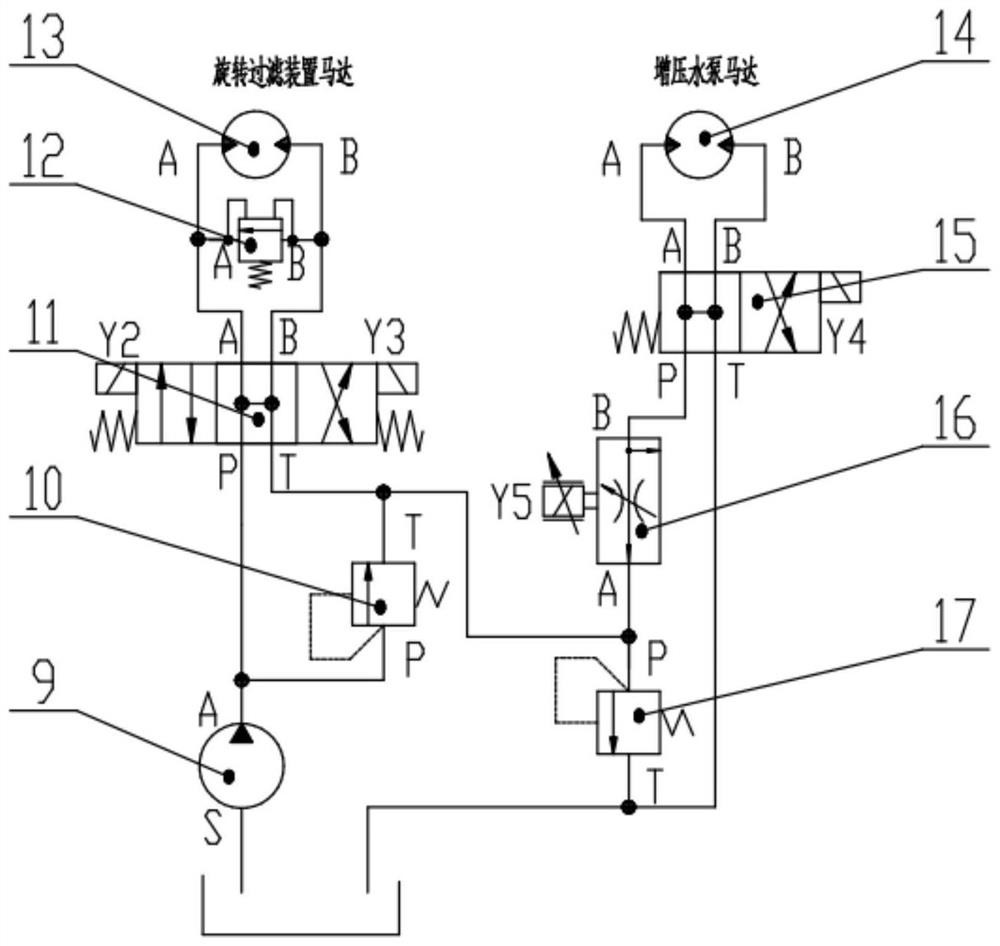

[0046] A sewage circulation hydraulic control system, comprising:

[0047] The electromagnetic reversing valve I11 is configured to control the switch and forward / reverse rotation of the motor 13 of the rotary filter device;

[0048] The solenoid reversing valve II15 is configured to control the switch of the booster water pump motor 14;

[0049] The electric proportional speed regulating valve 16 is configured to regulate the speed of the booster water pump motor 14 .

[0050] In some embodiments, such as figure 2 As shown, the sewage circulation hydraulic control system further includes: a two-way buffer valve 12 configured to prevent the rotary filter motor 13 from sucking air when the rotary filter motor 13 starts and stops.

[0051] In some embodiments, such as figure 2 As shown, the sewage circulation hydraulic control system further includes: a hydraulic pump 9, a first overflow valve 10, and a second overflow valve 17;

[0052] The S port of the hydraulic pump 9 ...

Embodiment 2

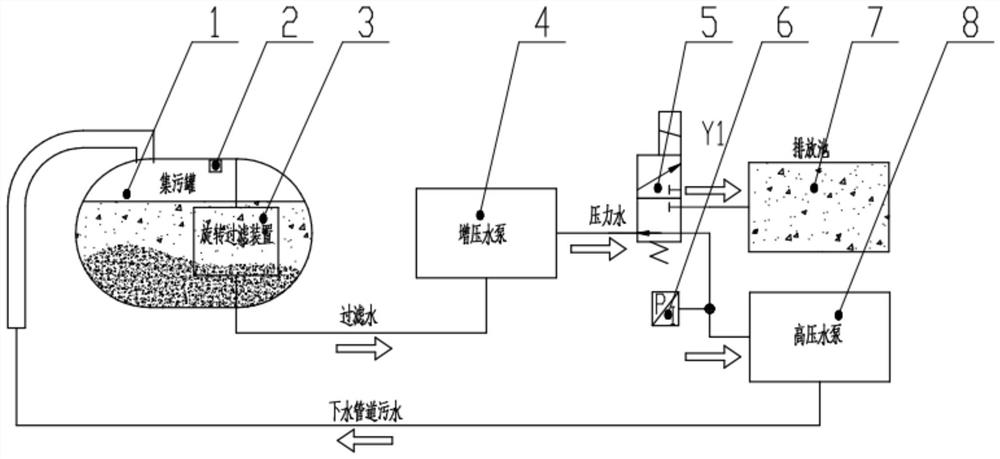

[0055] A dredging device, comprising: a sewage collection tank 1, a rotary filter device 3, a booster water pump 4, a three-way reversing valve 5, a discharge pool 7, a high-pressure water pump 8, and the above-mentioned sewage circulation hydraulic control system; figure 1 as shown,

[0056] The rotary filter device 3 is installed in the sewage collection tank 1, and is used for rotary filtration of the sewage in the sewage collection tank 1; the filtered water enters the booster water pump 4, and the outlet of the booster water pump 4 is respectively connected to the discharge through the three-way reversing valve 5 Pool 6, water inlet of high-pressure water pump 7, the outlet of said high-pressure water pump 7 is connected to the inlet of sewage collection tank 1 through the sewer pipe; and the switching between the sewage circulation mode and the sewage discharge mode is realized through the three-way reversing valve 5;

[0057] The rotary filtering device 3 is driven by a...

Embodiment 3

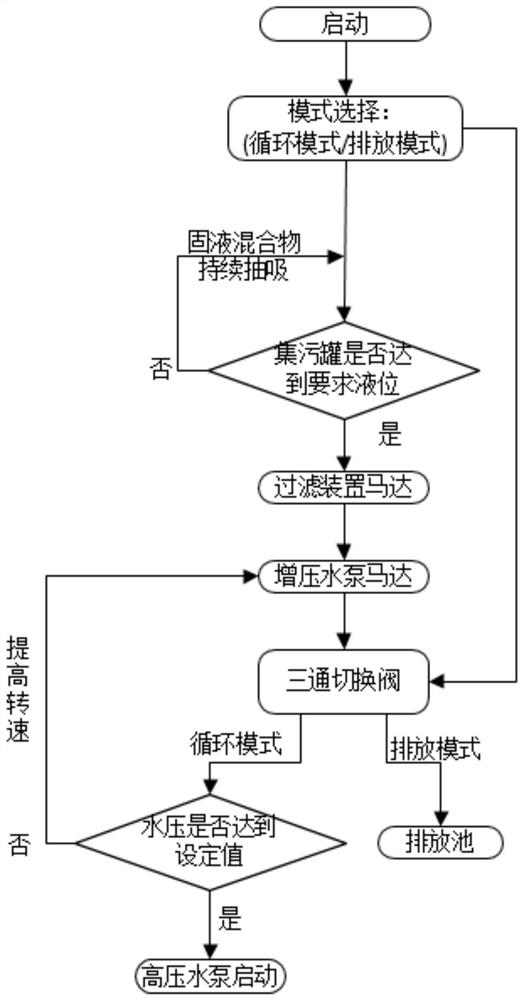

[0061] A dredging equipment control method, comprising:

[0062] Obtain liquid level information in the sewage collection tank;

[0063] According to the liquid level information in the sewage collection tank, it is judged whether the set liquid level is reached in the sewage collection tank;

[0064] In response to judging that the set liquid level has not been reached in the sewage collection tank, the mud-water mixture is sucked into the sewage collection tank 1;

[0065] Or, in response to judging that the set liquid level is reached in the sewage collection tank, an instruction is issued to control the operation of the rotary filter motor, forward / reverse rotation and booster water pump motor 14;

[0066] Determine the working mode, and switch between the sewage circulation mode and sewage discharge mode through the three-way reversing valve:

[0067] Sewage circulation mode, control the three-way reversing valve to make the pipeline between the booster water pump and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com