Water-cooled vehicle brake

A vehicle braking, water-cooled technology, applied in the direction of cooling brakes, brakes, vehicle components, etc., can solve the problem of easy entry of dust into the cooling channel, increasing difficulty, etc., to avoid wet road surface, improve utilization rate, and avoid temperature rise. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

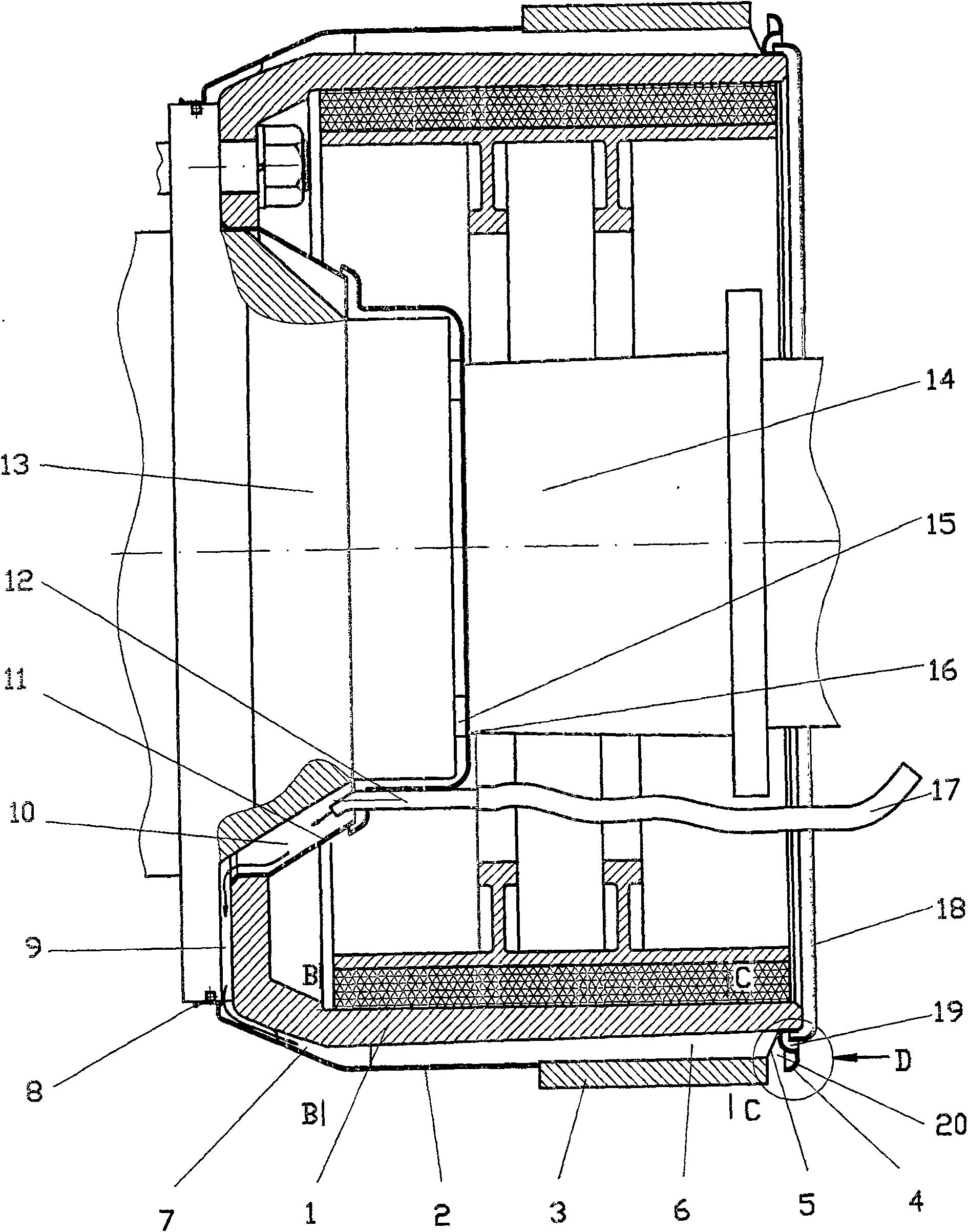

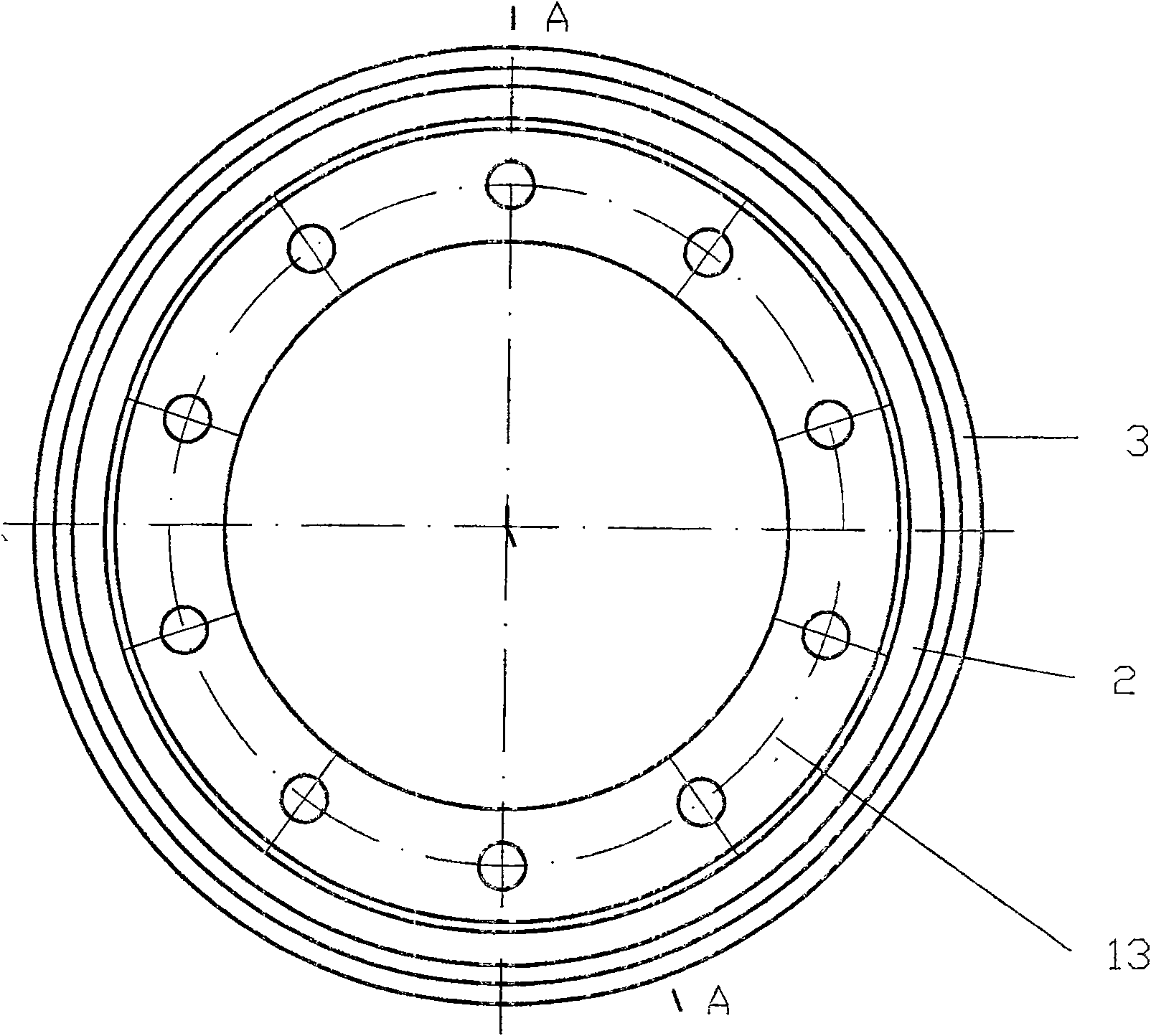

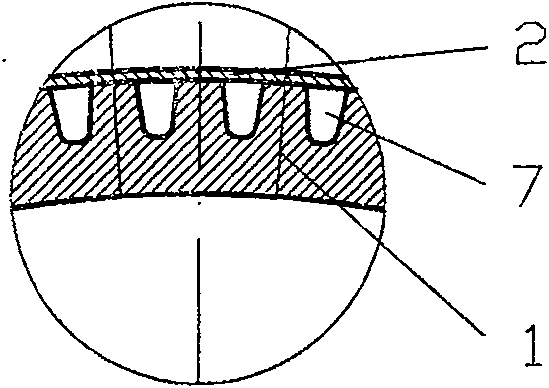

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] The water-cooled vehicle brake provided by the present invention comprises a wheel hub 13 installed on the car 14, a brake drum 1 arranged on the car 14 and the wheel hub 13, a brake drum 1 arranged in the brake drum 1 and fixed on the car 14. The inner dust cover 16, the water jacket 2 and the reinforcement hoop 3 arranged on the outside of the brake drum 1, the axial ribs 3 in the water jacket 2 and the evaporative cooling channels 6 between the adjacent ribs at intervals. Between the moving drum 1 and the hub 13 there are inner water cavities 7, 9, 10 communicating with the evaporative cooling channel 6, the water delivery pipe 17 is fixed on the inner dust cover 16, and the nozzle 12 at the end is placed in the inner water cavity 10, so as to deliver cooling water to the inner water chambers 10, 9, 7 through the water delivery pipe 17 and the nozzle 12 at it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com