Device for testing combustion performance of power battery

A combustion performance and testing device technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems of inability to simulate, lack of quantitative comparison methods, etc., and achieve the effect of ensuring consistency and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

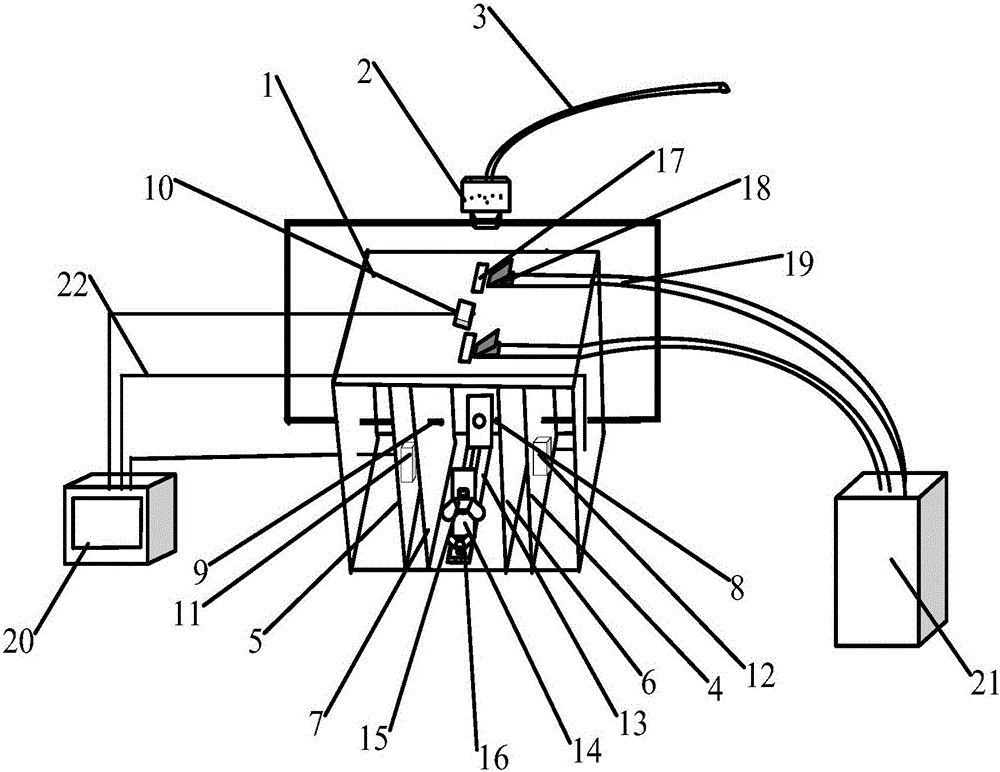

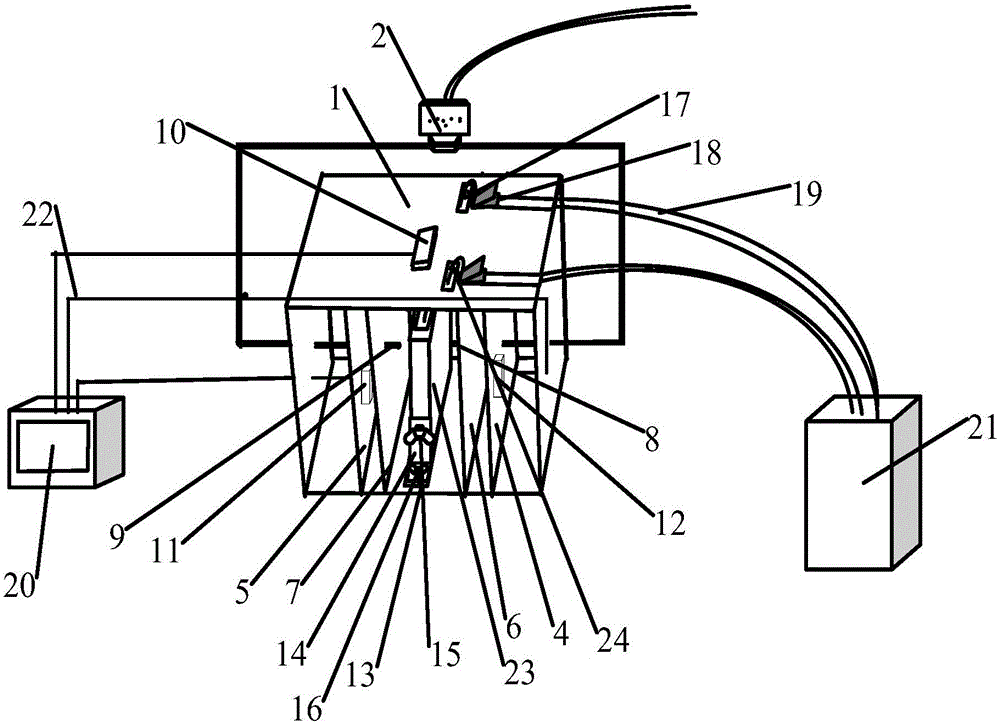

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The numbers in the figure are: 1 is the explosion-proof box, 2 is the quantitative gas valve, 3 is the external gas pipeline, 4 is the right pressure sensor platform, 5 is the left pressure sensor platform, 6 is the right explosion-proof net, 7 is the left explosion-proof Net, 8 is the right combustion port, 9 is the left combustion port, 10 is the explosion-proof valve pressure sensor, 11 is the left pressure sensor, 12 is the right pressure sensor, 13 is the battery fixing platform track, 14 is the battery fixing support fixture, 15 is the upper fixing nut, 16 is the bottom fixing nut, 17 is the external lead wire port, 18 is the wire clip, 19 is the external lead wire, 20 is the pressure treatment system, 21 is the charge and discharge cabinet, 22 is the pressure sensor connection line, 23 is the battery , 24 is a battery co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com