Low-frequency magnetic flux leakage sensor magnetic-sensitive element clamping combined multi-axis mobile device

A technology of magnetic flux leakage sensor and magnetic sensitive element, which is applied in the direction of material magnetic variable, etc., can solve the problems that the number, direction and position of magnetic sensitive elements cannot be adjusted, and the detection effect of low frequency magnetic flux leakage sensor cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with content of the present invention provide following embodiment:

[0023] Installation example of multi-axis moving device for clamping magnetic sensitive elements of large-size low-frequency magnetic flux leakage sensor:

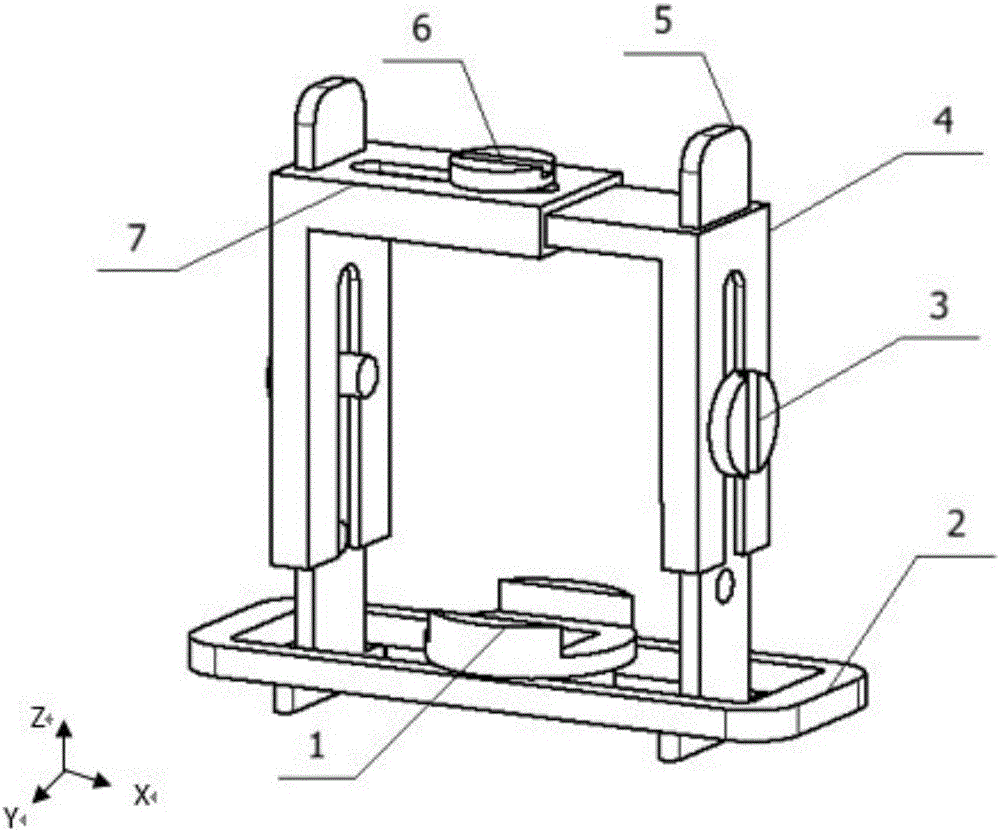

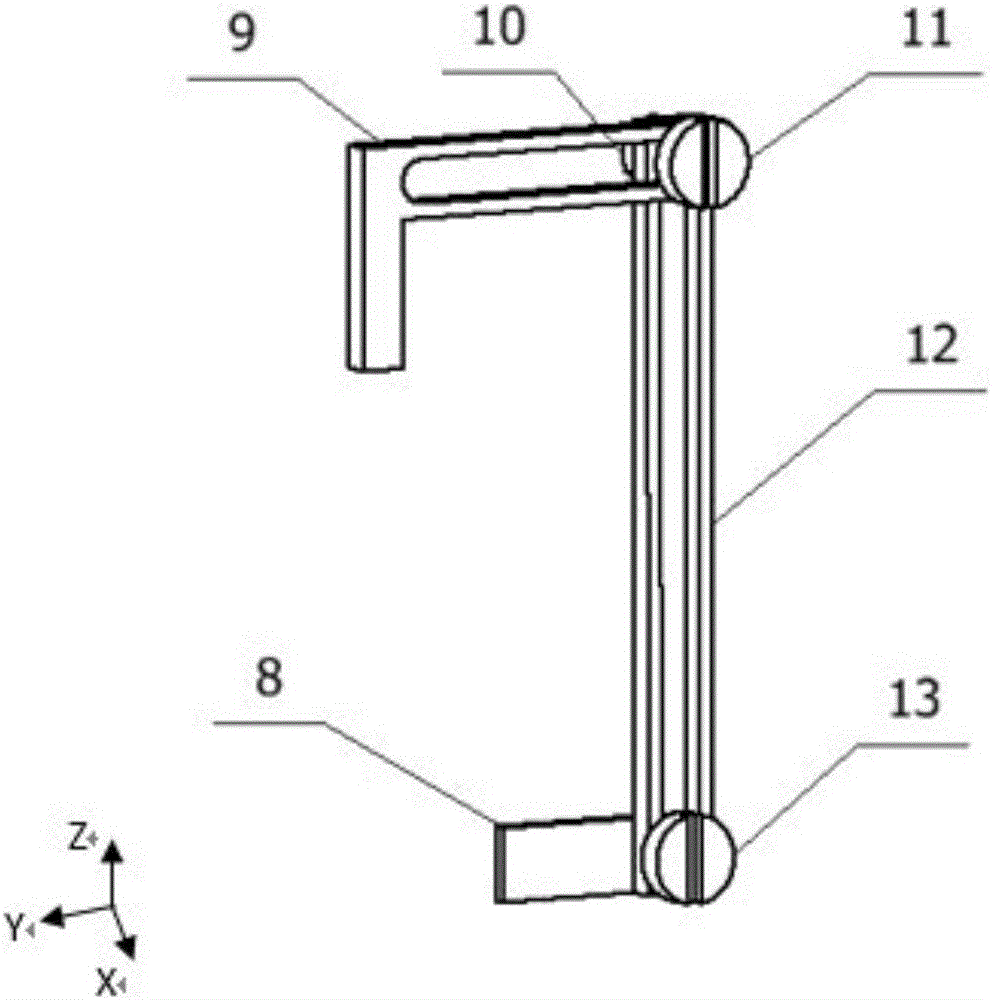

[0024] 1) First, for a U-shaped low-frequency magnetic flux leakage sensor with a size of 70mm×40mm×56mm and a distance between two poles of 30mm, select a multi-axis moving device for clamping the magnetic sensitive element of a large-scale low-frequency magnetic flux leakage sensor (as attached figure 1 shown).

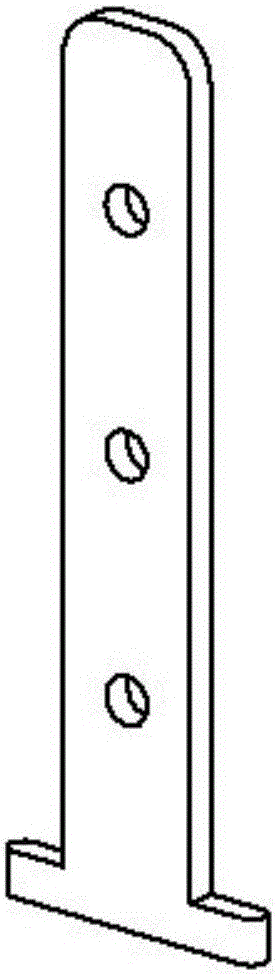

[0025] 2) Insert a single commonly used magnetic sensitive element—Hall element (T094 package) into the fixed slider 1 through a highly elastic polymer material (such as rubber) that matches the size of the slot in the fixed slider. Slide and rotate the fixed slider 1 in the tray 2 to find the detection angle and detection position that meet the experimental design, and the Hall element angle and the x-direction de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com