Array substrate, preparing method of array substrate, display panel and display device

A technology for an array substrate and a display area, which is applied in the fields of an array substrate and a preparation method thereof, a display panel, and a display device, can solve the problems affecting product quality, signal line breakage, resistance to voltage difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

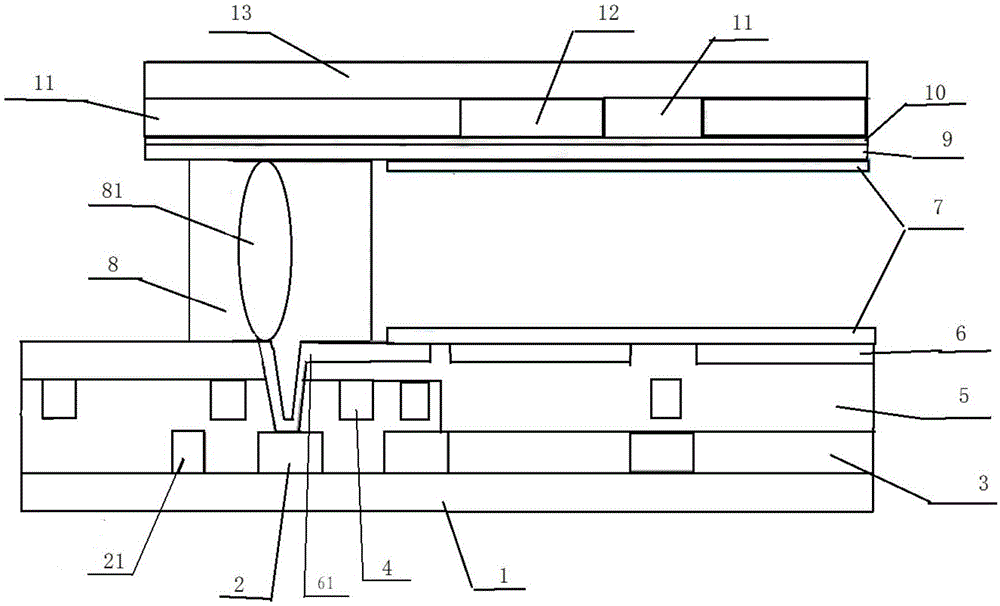

[0055] Such as image 3 As shown, this embodiment provides an array substrate, including a display area and a peripheral area, the peripheral area is provided with signal wiring, and a protective layer 62 is provided in a preset area of the peripheral area, and the preset area includes at least Areas with signal traces.

[0056] For the array substrate provided in this embodiment, since the protective layer 62 is provided in the predetermined area of the peripheral area, the protective layer 62 can prevent the gold balls 81 in the sealant 8 from affecting the signal transmission of the array substrate after being pressed. The line has adverse effects. That is to say, it can prevent the above-mentioned gold balls 81 from piercing the passivation layer 5 , thereby causing a short circuit of the signal lines.

[0057] Optionally, the protection layer 62 is made of metal or metal oxide. Generally, metal or metal oxide has high hardness, and at the same time, corresponding t...

Embodiment 2

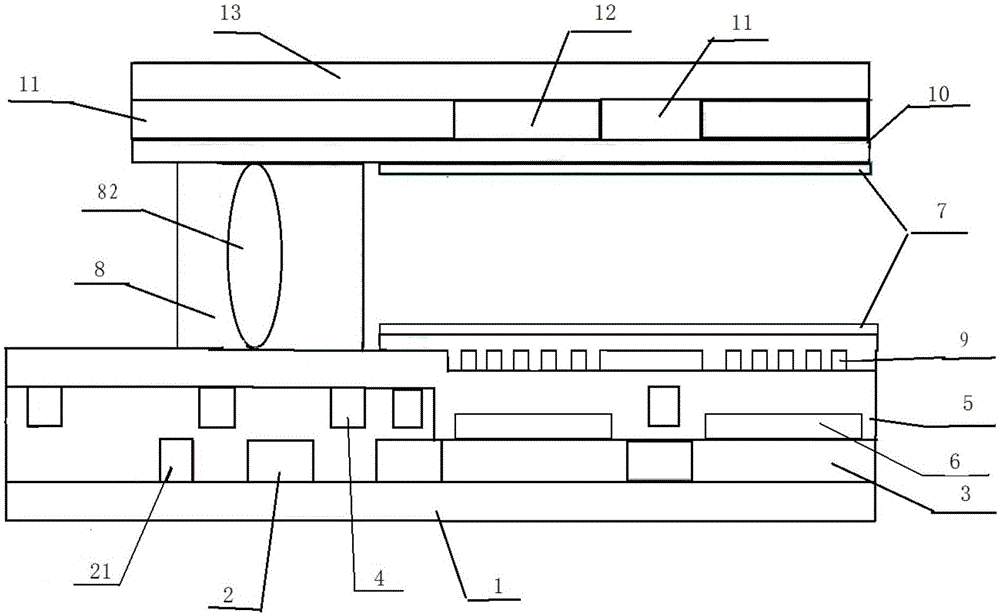

[0072] Such as Figure 4 As shown, this embodiment provides an array substrate, including a display area and a peripheral area, the peripheral area is provided with signal wiring, and a protective layer 62 is provided in a preset area of the peripheral area, and the preset area includes at least Areas with signal traces.

[0073] For the array substrate provided in this embodiment, since the protective layer 62 is provided in the predetermined area of the peripheral area, the protective layer 62 can prevent the supports such as silicon balls 82 and / or glass fibers in the sealant 8 from being compressed. It will adversely affect the signal wiring of the array substrate. That is to say, it can prevent the silicon ball 82 and / or glass fiber and other supports from piercing the passivation layer 5 , thereby causing breakage of the signal wiring.

[0074] Optionally, the protection layer 62 is made of metal or metal oxide. In general, metal or metal oxide has high hardness a...

Embodiment 3

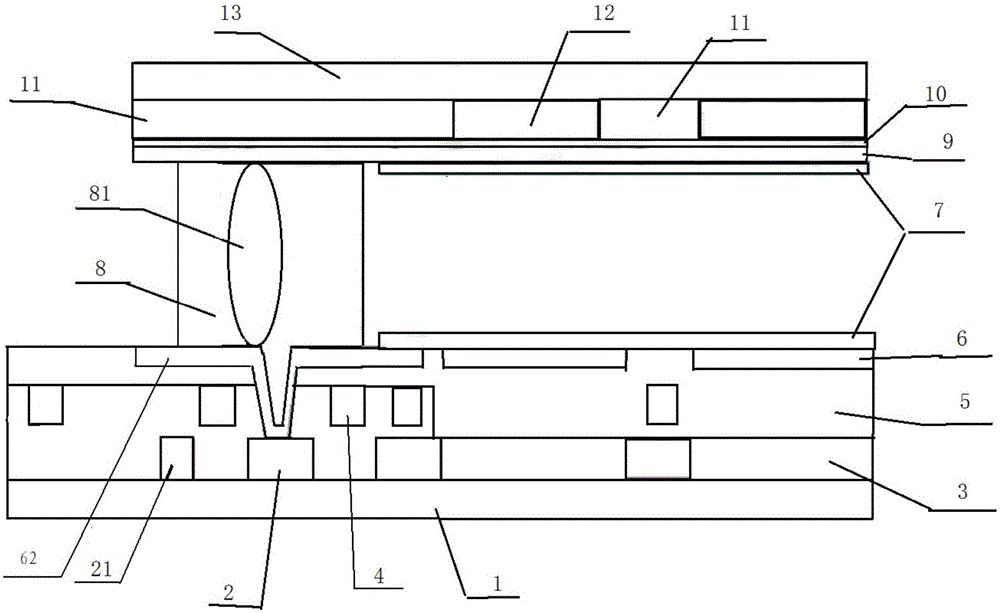

[0088] This embodiment provides a method for preparing an array substrate, including the following steps:

[0089] forming thin film transistors on the base substrate;

[0090]The pixel electrode 6 is formed by a patterning process on the base substrate on which the thin film transistor is formed; wherein, the protective layer 62 and the pixel electrode 6 are formed by one patterning process. The protective layer 62 and the pixel electrode 6 are formed through one patterning process, thereby saving process steps and reducing manufacturing costs.

[0091] Optionally, include the following steps:

[0092] On the base substrate, form a gate pattern in the display area of the array substrate through a patterning process, and a gate line 21 and a common electrode line 2 arranged on the same layer as the gate and located in the peripheral area of the array substrate graphics;

[0093] forming the pattern of the gate insulating layer 3 through a patterning process, wherein a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com