High-precision constant-temperature controller and method based on fuzzy self-adaptive PID control

A fuzzy self-adaptive, constant temperature controller technology, applied in auxiliary controllers with auxiliary heating devices, temperature control using electric methods, etc., can solve problems such as PID parameters cannot meet system requirements, and achieve reliable scientific experimental basis, Precise control of effects, ensuring high reliability of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

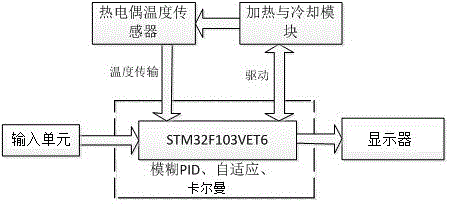

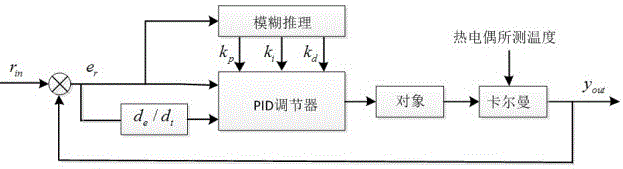

[0027] The present invention is based on figure 1 The shown constant temperature controller is implemented. The system adopts modular design and consists of four parts: STM32F103VET6 main control chip, temperature data acquisition module, heating and cooling module, input and display module. Among them, the temperature data acquisition module uses a thermocouple temperature sensor to measure the furnace temperature in the heating furnace, and the heating and cooling module uses 6 small, high-precision, adjustable heating power radiant tubes to realize the heating function. The material of the radiant tubes is alumina ; The cooling function is realized by the freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com