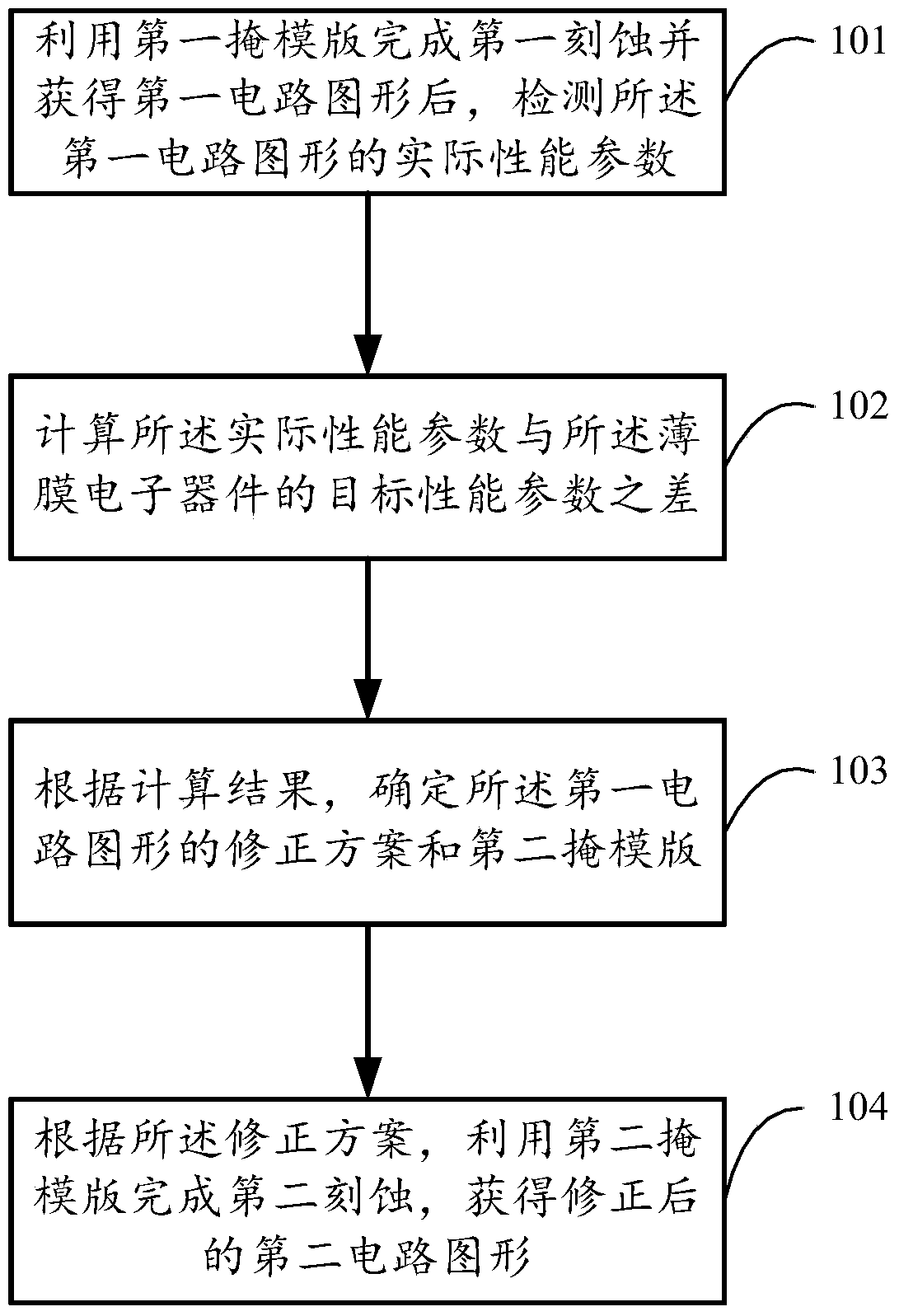

Production control method, device and system of a thin film electronic device

A production control method and technology for electronic devices, applied in the direction of electrical components, semiconductor/solid-state device testing/measurement, circuits, etc., can solve problems such as increased production costs, small scope of modification, inability to achieve circuit pattern modification, etc., and reduce corrections. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

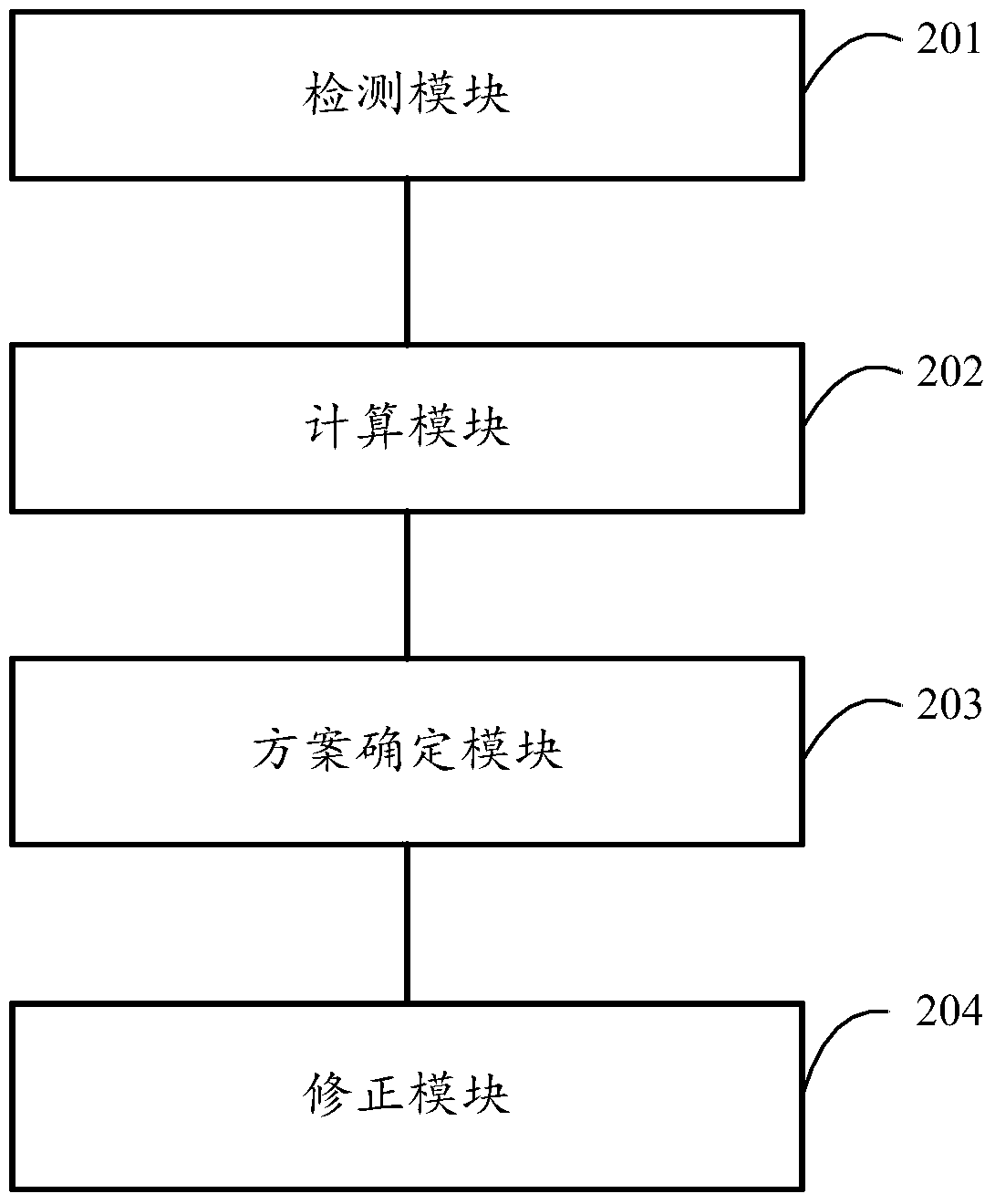

Method used

Image

Examples

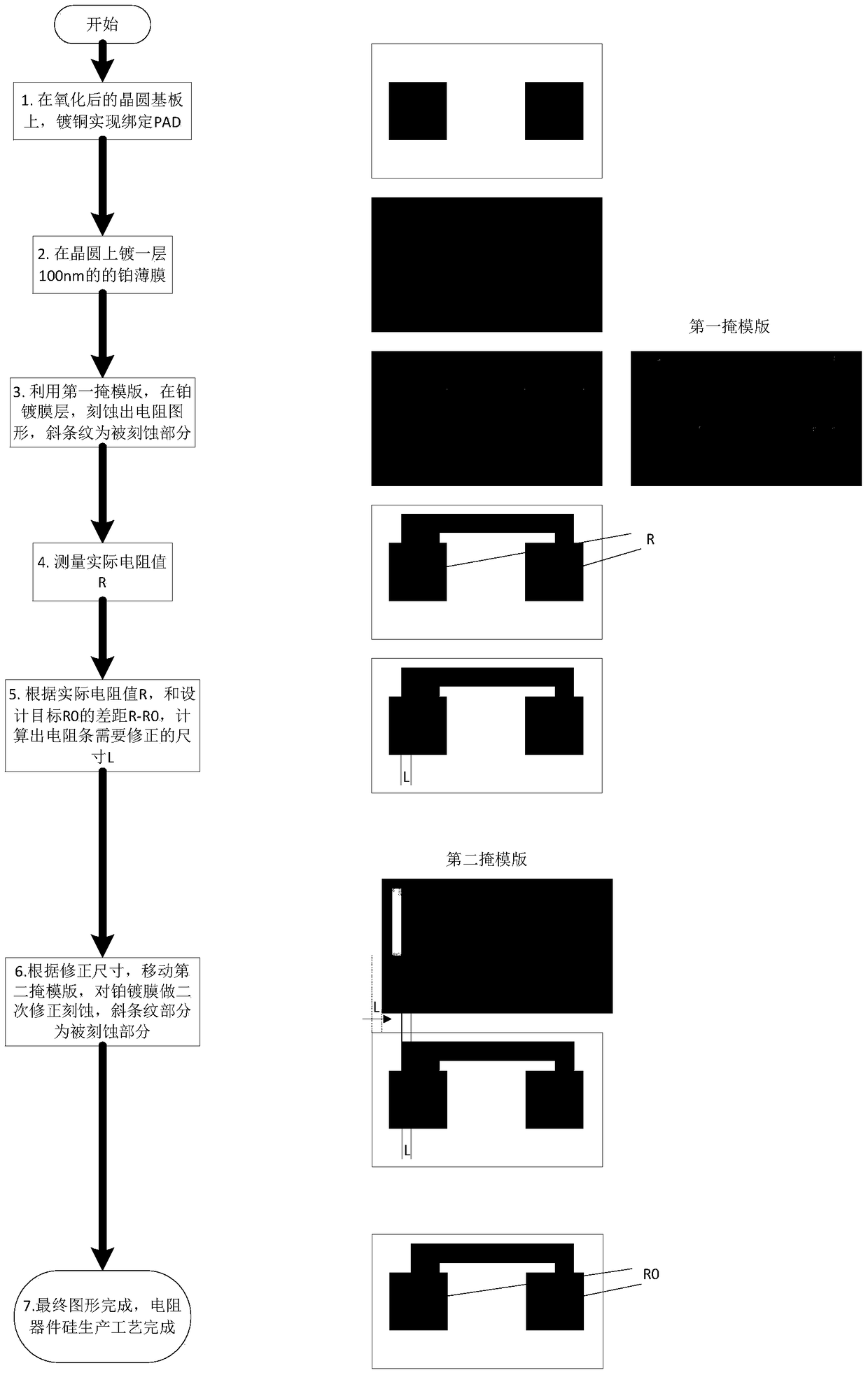

Embodiment 1

[0085] Apply the production control method of the above-mentioned thin-film electronic device to the following scenario, that is, the thin-film electronic device to be produced is a resistor, and the target resistance value should be R0, and the actual resistance value R of the first circuit pattern obtained after the first etching is . image 3 A schematic diagram of the circuit diagram of the production flow of the resistor and the corresponding thin film electronic device for each step by applying the production control method provided by the present invention. The production process includes:

[0086] 1. On the oxidized wafer substrate, copper plating is used to bond the PAD;

[0087] 2. Coating a layer of 100nm platinum film on the wafer;

[0088] 3. Use the first mask to etch the resistance pattern on the platinum coating layer, and the oblique stripes are the etched parts;

[0089] 4. Measure the actual resistance value R;

[0090] 5. According to the difference R-R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com