Molten metal discharging device and method for discharging molten metal

A molten metal and molten state technology, applied in the field of molten metal ejection devices, can solve the problems of inability to insert shafts, unstable ejection volume, etc., to reduce the contact area, reduce the fluctuation of the ejection volume, and achieve high-precision control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

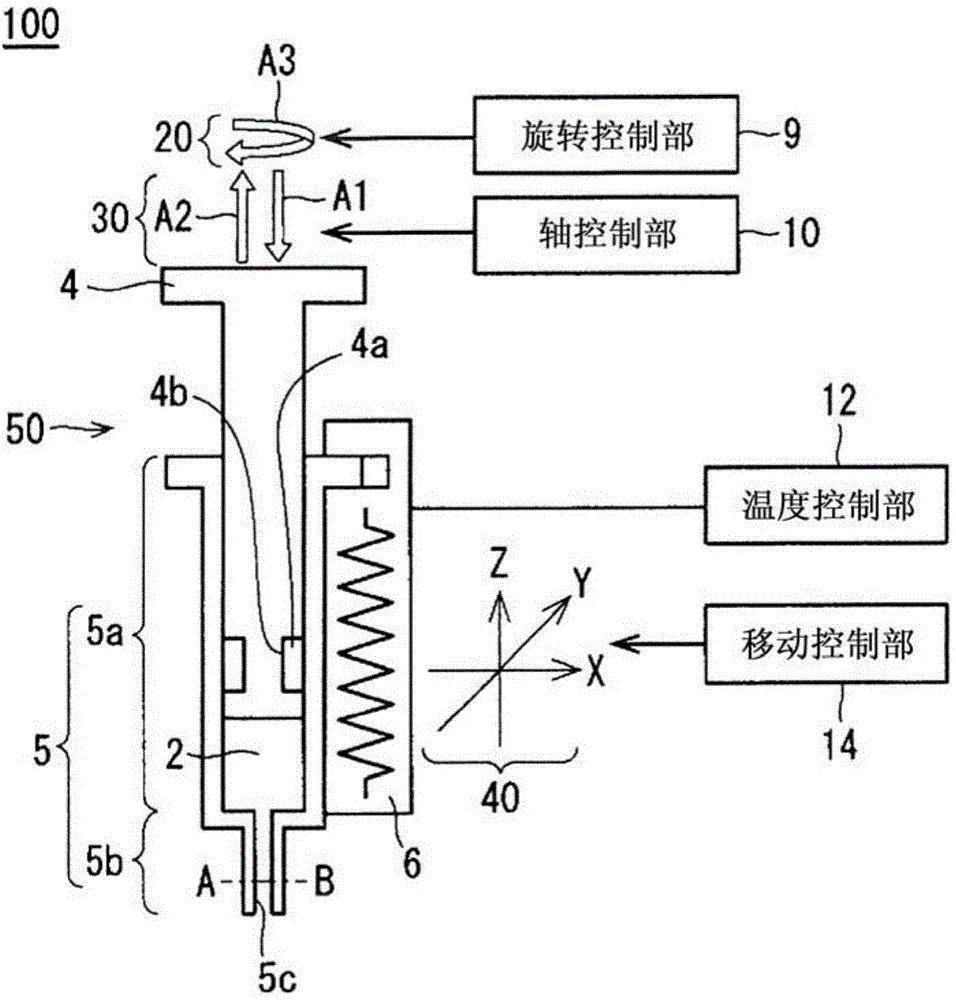

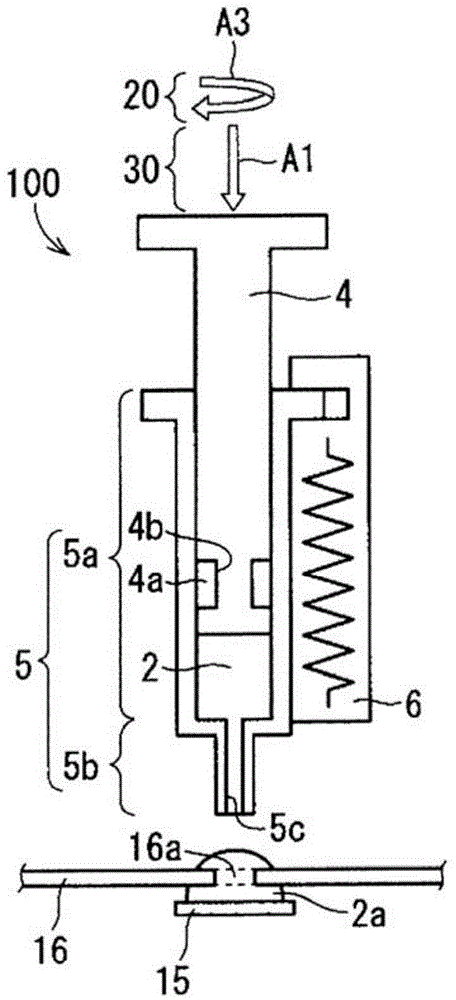

[0023] figure 1 It is a figure which shows the schematic structure of the molten metal discharge apparatus 100 in this Embodiment 1. The molten metal discharge apparatus 100 has the discharge mechanism part 50, the rotation control part 9, the shaft control part 10, the movement control part 14, and the temperature control part 12. In addition, below, in each figure, the same code|symbol represents the same or a corresponding part. The discharge mechanism unit 50 has a cylinder 5 , a shaft 4 , a cylinder heat-retaining heater 6 , a rotation mechanism 20 , an actuator 30 , and a movement mechanism 40 .

[0024] The cylindrical pressure cylinder 5 is comprised from the shaft sliding part 5a and the nozzle 5b. The inner diameter of the nozzle 5b is smaller than the inner diameter of the shaft sliding portion 5a. The nozzle 5 b sucks the molten metal 2 and accommodates it in the pressure cylinder 5 . Moreover, the nozzle 5b discharges the molten metal 2 accommodated in the pre...

Embodiment approach 2

[0056]

[0057] Figure 5 It is a figure which shows the structure of the molten metal discharge apparatus 200 in this Embodiment 2. In Embodiment 2, compared to the molten metal ejection device 100 of Embodiment 1 ( figure 1 ), and a gas pipe 7 is also provided in the shaft 4. The gas pipe 7 is connected to a gas tank (not shown), and the gas tank is filled with an inert gas such as nitrogen. The configuration is such that an inert gas can be injected into the inside of the nozzle 5 b through the gas pipe 7 . The other configurations are the same as those in Embodiment 1, and thus description thereof will be omitted. In addition, in Figure 5 in, omit figure 1 The illustration of the rotation mechanism 20 , the actuator 30 , the movement mechanism 40 , the rotation control unit 9 , the shaft control unit 10 , the movement control unit 14 and the temperature control unit 12 in FIG. from Figure 6 to Figure 8 Also omitted in the same manner.

[0058]

[0059] In the...

Embodiment approach 3

[0067]

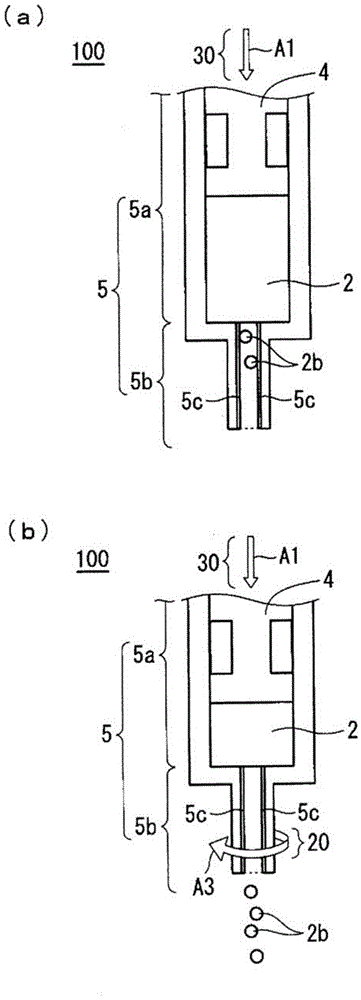

[0068] Figure 7 (a), (b) is a figure which shows the structure of the molten metal discharge apparatus 300 in this Embodiment 3. Figure 7 (a) is the state after raising the shaft 4, Figure 7 (b) is the state which lowered the shaft 4 to the front-end|tip of the nozzle 5b.

[0069] Such as Figure 7 As shown in (a), the cross section inside the nozzle 5b along the extending direction of the nozzle 5b has a narrow shape toward the tip of the opening. Specifically, for example, the shape inside the nozzle 5b is conical. In addition, the tip of the shaft 4 has a tapered shape. Such as Figure 7 As shown in (b), the tip of the shaft 4 is shaped to fit inside the nozzle 5b without a gap. In addition, the shape inside the nozzle 5b may be a triangular pyramid, a quadrangular pyramid, etc. other than a conical shape. The other configurations are the same as those in Embodiment 1, and thus description thereof will be omitted.

[0070]

[0071] When the shaft 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com