Paraffin-based air-cooled and water-cooled combined cooling device

An air-cooled, water-cooled, and heat-dissipating device technology, which is applied to electrical components, electrical solid devices, circuits, etc., can solve the problems of large temperature difference on the wall surface, small amount of refrigerant, and low heat dissipation capacity of the radiator, so as to ensure normal operation and improve life expectancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

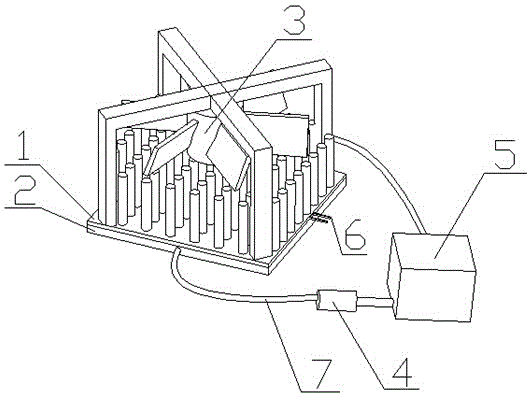

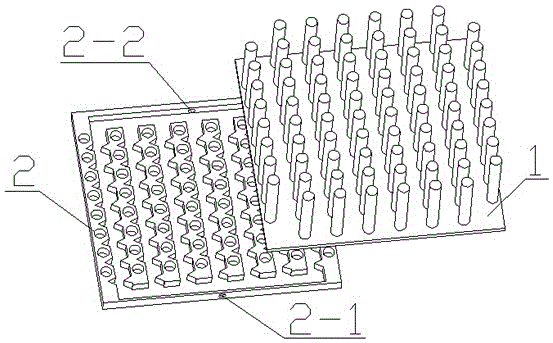

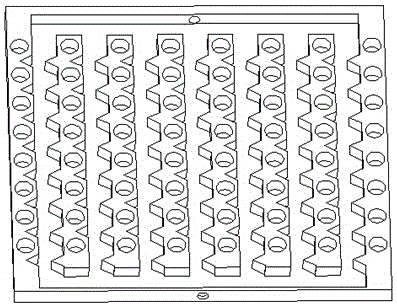

[0039]The paraffin-based air-cooled water-cooled combined heat dissipation device of this embodiment includes a heat dissipation cover plate, the heat dissipation cover plate is equipped with heat dissipation fins, a fan is arranged above the heat dissipation fins, and a heat dissipation cold plate is also included. The heat dissipation cold plate is arranged under the heat dissipation cover plate, and the heat dissipation cover plate is provided with a plurality of runner grids, one side of the runner grids is provided with protrusions, and the other side of the runner grids is There is a groove on one side, and a plurality of holes are opened on the runner grid, and the holes are filled with metal foam and paraffin, and the holes are matched with the heat dissipation fins on the heat dissipation cover plate and They are connected together to form a sealed space; the heat dissipation cold plate is provided with a coolant inlet and a coolant outlet, and the coolant inlet and co...

Embodiment 2

[0041] The paraffin-based air-cooled water-cooled combined heat dissipation device of this embodiment includes a heat dissipation cover plate, the heat dissipation cover plate is equipped with heat dissipation fins, a fan is arranged above the heat dissipation fins, and a heat dissipation cold plate is also included. The heat dissipation cold plate is arranged under the heat dissipation cover plate, and the heat dissipation cover plate is provided with a plurality of runner grids, one side of the runner grids is provided with protrusions, and the other side of the runner grids is There is a groove on one side, and a plurality of holes are opened on the runner grid, and the holes are filled with metal foam and paraffin, and the holes are matched with the heat dissipation fins on the heat dissipation cover plate and Connected together to form a sealed space; the heat dissipation cold plate is provided with a coolant inlet and a coolant outlet, and the coolant inlet and coolant ou...

Embodiment 3

[0043] The paraffin-based air-cooled water-cooled combined heat dissipation device of this embodiment includes a heat dissipation cover plate, the heat dissipation cover plate is equipped with heat dissipation fins, a fan is arranged above the heat dissipation fins, and a heat dissipation cold plate is also included. The heat dissipation cold plate is arranged under the heat dissipation cover plate, and the heat dissipation cover plate is provided with a plurality of runner grids, one side of the runner grids is provided with protrusions, and the other side of the runner grids is There is a groove on one side, and a plurality of holes are opened on the runner grid, and the holes are filled with metal foam and paraffin, and the holes are matched with the heat dissipation fins on the heat dissipation cover plate and Connected together to form a sealed space; the heat dissipation cold plate is provided with a coolant inlet and a coolant outlet, and the coolant inlet and coolant ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com