Thyristor converter valve tower for high-voltage direct-current power transmission

A technology of thyristor converter valve and high-voltage direct current transmission, which is applied in the direction of output power conversion device, conversion of AC power input to DC power output, circuit, etc., can solve the problems of large structural span, poor seismic performance and poor stability, etc. Achieve the effect of strong earthquake resistance, light weight and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

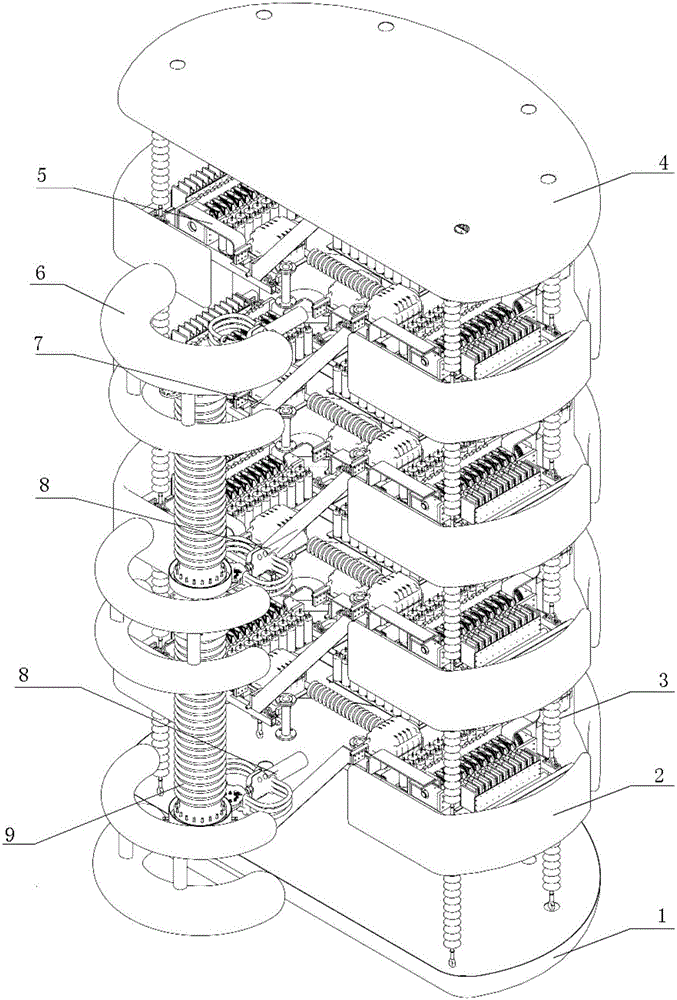

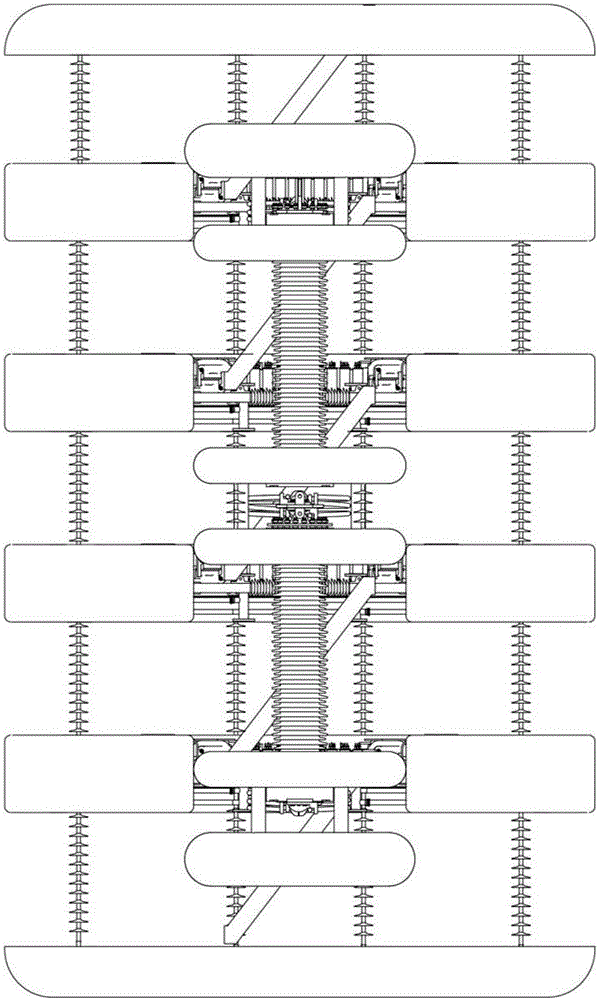

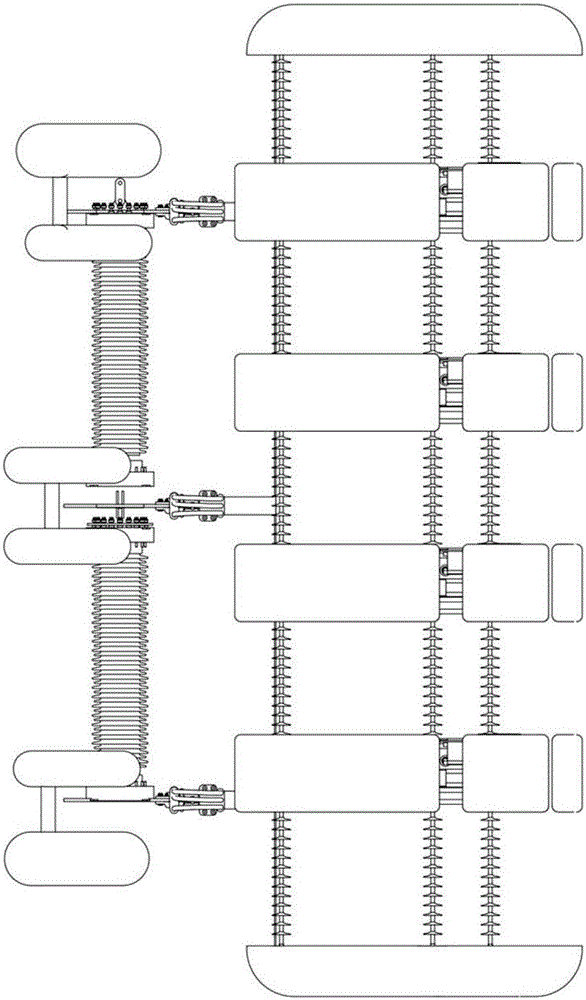

[0051] The thyristor converter valve tower for high-voltage direct current transmission provided by the present invention is as follows: Figure 1-3 As shown: it includes lightning arresters and valve tower bodies arranged vertically and parallel to each other. The valve tower body includes top shields 4 and bottom shields 1 arranged in the horizontal direction and thyristor converter valves parallel to each other between the top and bottom shields. module. The valve tower adopts a modular design, and the independent thyristor converter valve valve tower is convenient for transportation, installation and commissioning on the project site.

[0052] attached Figure 1-3 There are four layers of thyristor converter valve modules. From top to bottom, the first and second layers of thyristor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com