Thick steel plate with excellent low temperature toughness

A kind of thick steel plate, extremely low temperature technology, applied in the field of thick steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

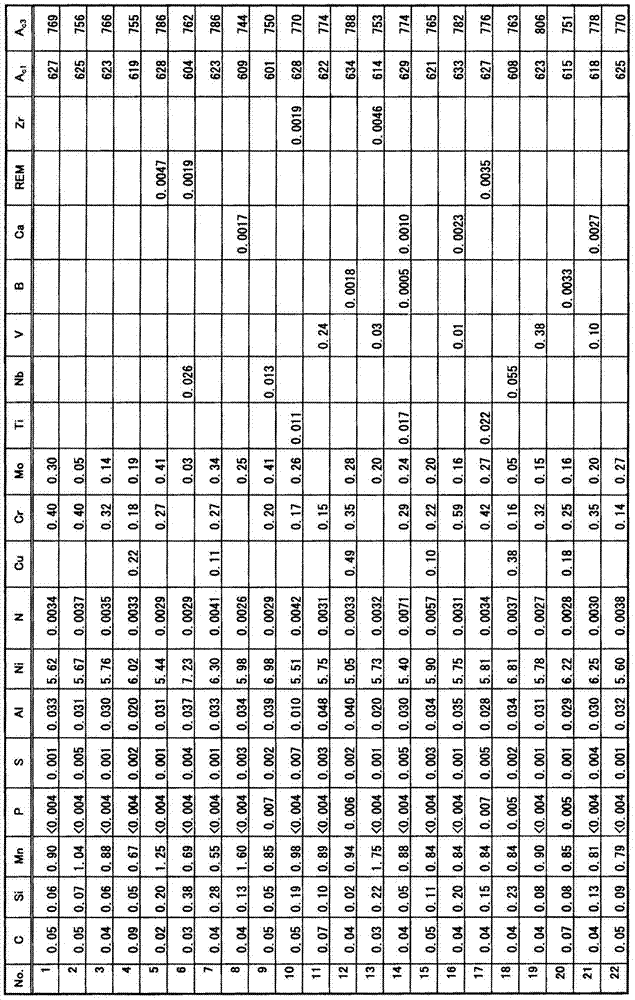

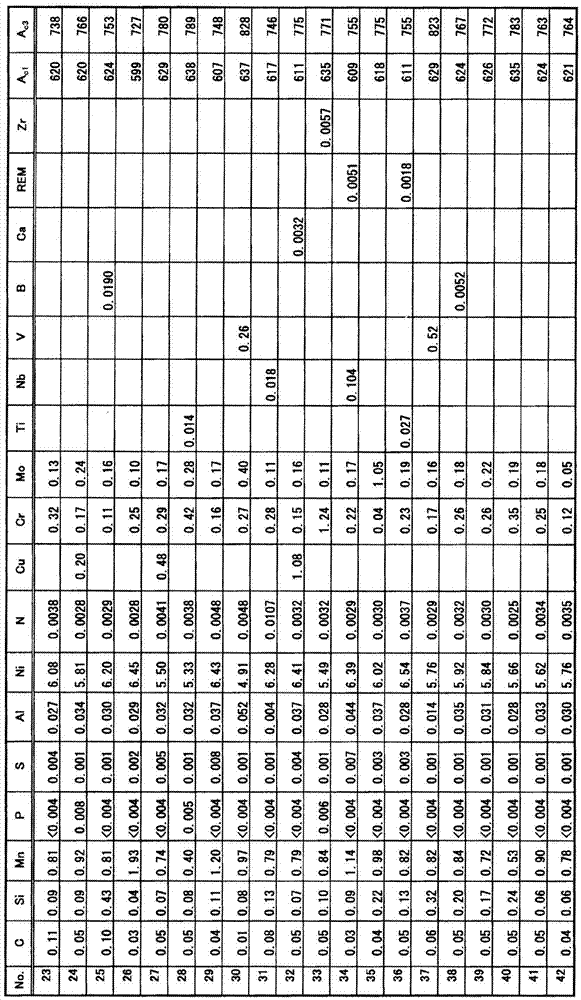

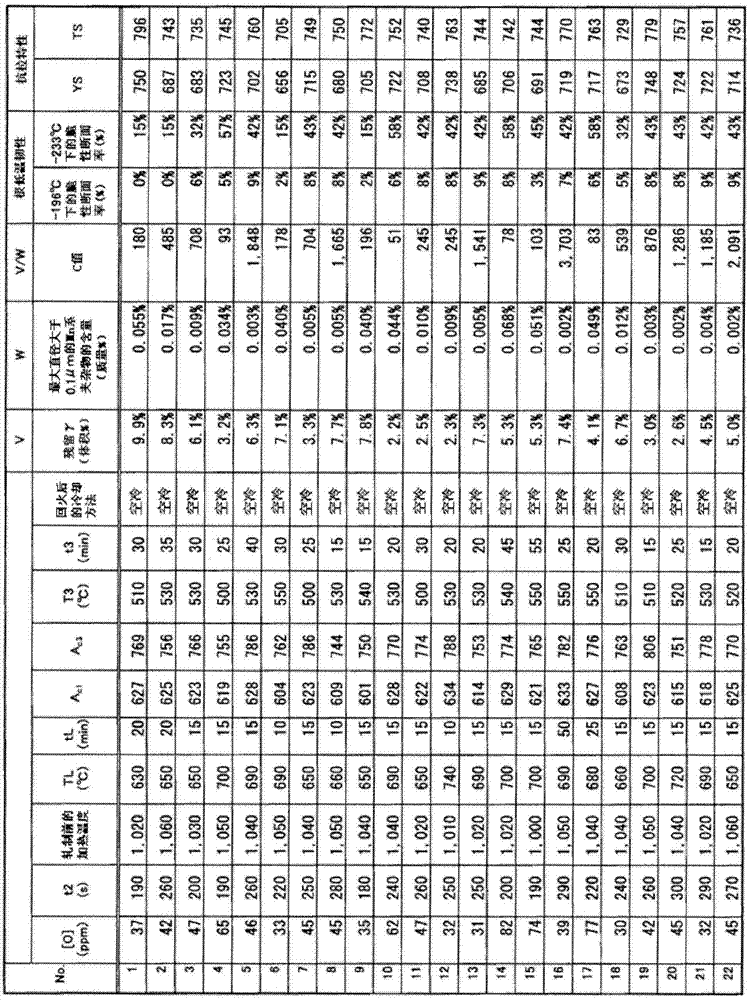

Embodiment 1

[0116] Use vacuum melting furnace (150kgVIF), with the smelting condition shown in table 2, smelt the test steel of composition shown in table 1 (remainder: iron and unavoidable impurity, unit is mass %), after casting, by heat Forging to make steel ingots of 150mm×150mm×600mm. In this embodiment, as the REM, a mixed rare earth metal containing about 50% of Ce and about 25% of La is used. In addition, the order of adding deoxidizing elements is Si, Mn (simultaneously added)→Al when optional components are not contained; on the other hand, when optional components containing Ti, REM, Zr, and Ca are contained, Si, Mn (simultaneously added) →Al→Ti→REM, Zr, Ca (simultaneously added). In addition, in Table 2, [O] is the amount of dissolved oxygen (ppm) before adding Al, and t2 is the cooling time (seconds) at 1500 to 1450° C. during casting. Cooling at 1500-1450°C is controlled by air cooling or water cooling so as to achieve the above-mentioned cooling time.

[0117] Next, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com