Working method of a corn harvester with a beard and ear separation device

A technology of corn harvester and working method, which is applied in the direction of harvester, agricultural machinery and implements, agriculture, etc., and can solve the problems of labor and fuel consumption, complex design structure, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

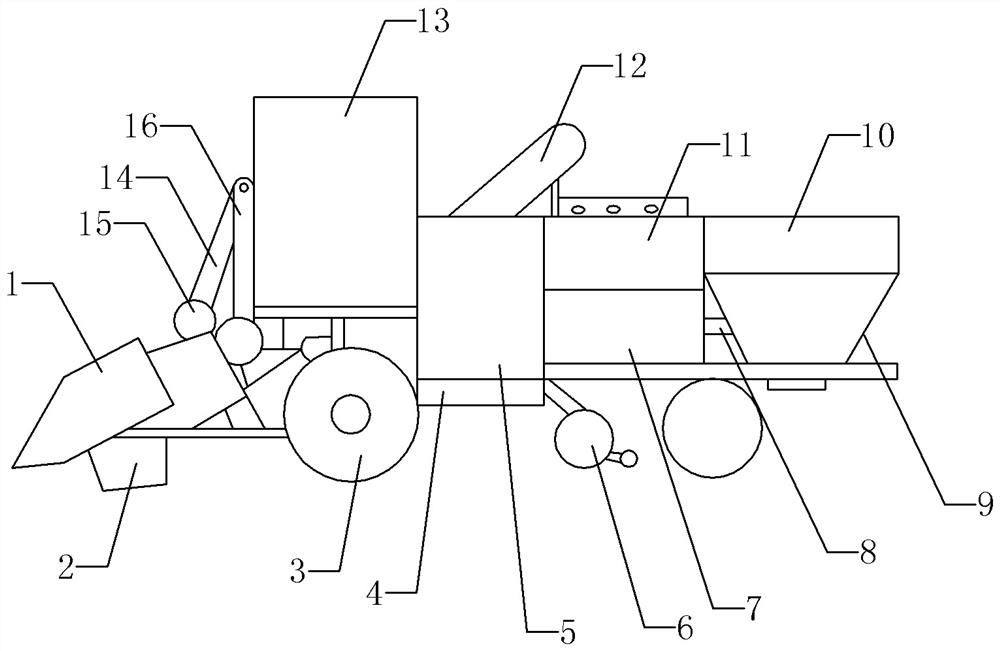

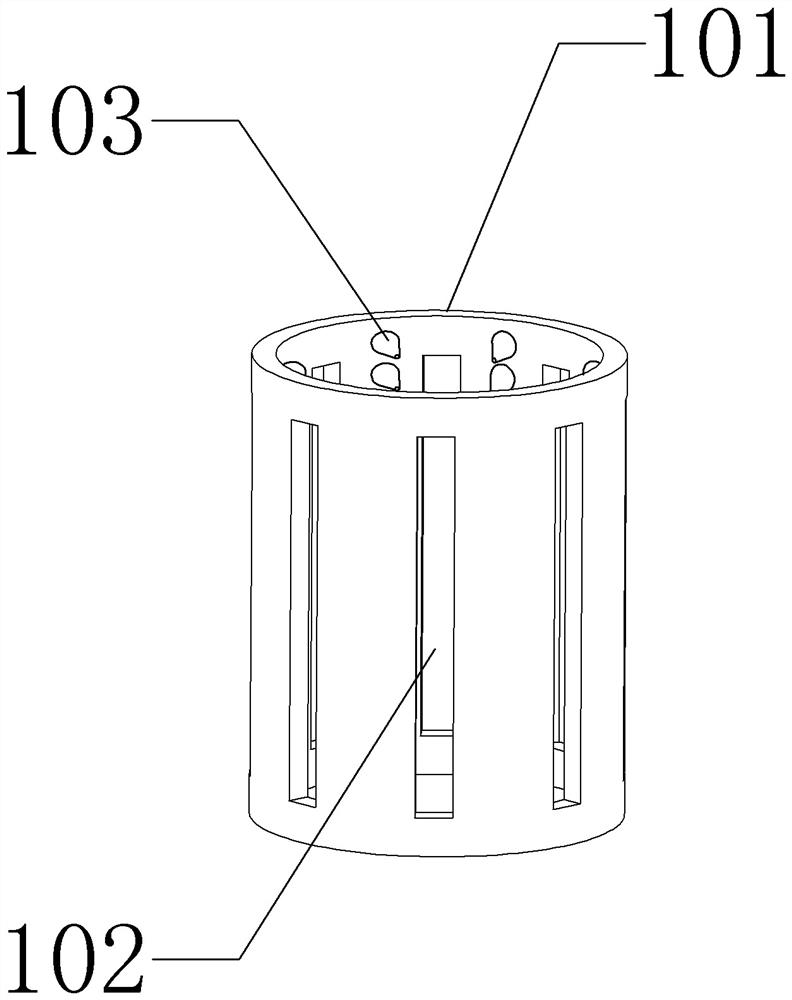

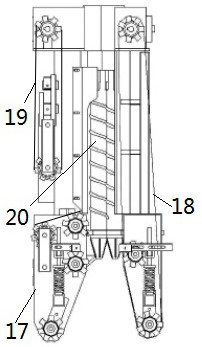

[0023] Instructions attached figure 1 The reference signs in include: cutting platform 1, cutting device 2, traveling wheel 3, traveling chassis 4, power mechanism 5, field returning machine 6, cleaning device 7, conveying path 8, hopper 9, beard ear separation device 10, Peeling device 11, lifter 12, cab 13, second support arm 14, climbing wheel 15, first support arm 16.

[0024] as attached figure 1 In the shown corn harvester, the power mechanism is arranged on the upper part of the walking chassis and is located in the middle of the whole machine, and the driver's cab is arranged on the walking chassis and is located in front of the power mechanism. The traveling wheels include front traveling wheels and rear traveling wheels, and the front traveling wheels and the rear traveling wheels are respectively located on both sides of the traveling chassis. The front of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com