Industrial control computer (IPC)-based cigarette making machine tobacco rod weight control and quality detection integrated device and method

A technology of weight control and cigarette making machine, which is applied in the fields of tobacco, paper cigarette manufacturing, application, etc., can solve the problems of high missed and false reject rate of cigarettes, inconvenient maintenance of tobacco factory equipment, large fluctuation of cigarette weight, etc. Fast speed, less self-developed circuit boards, less false reject rate and less false reject rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

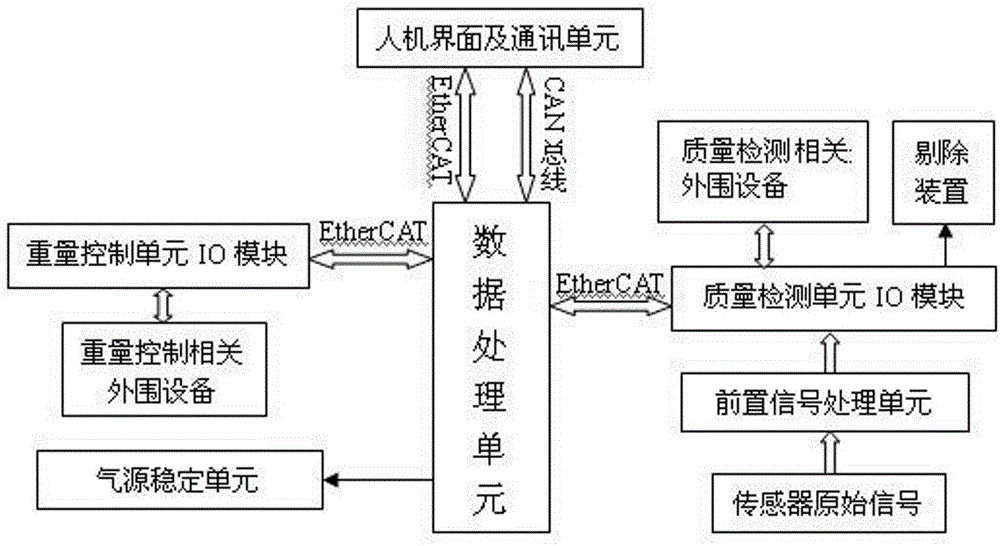

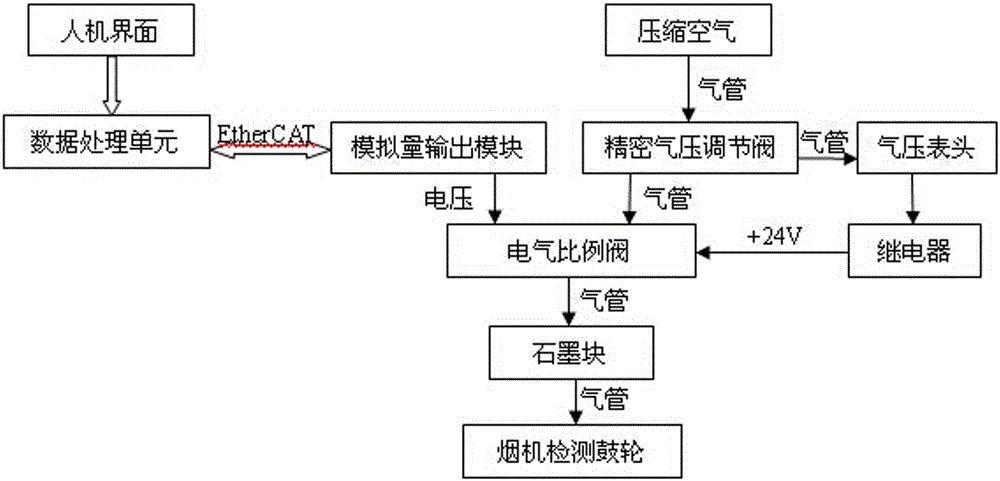

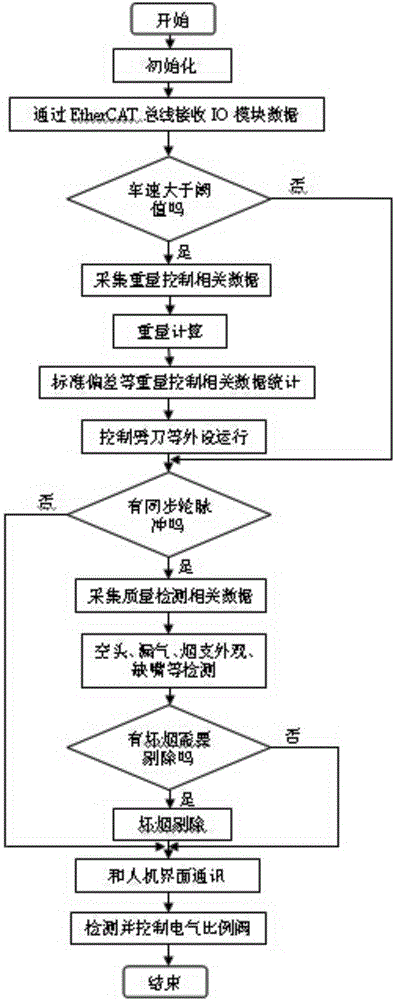

[0026] Embodiment 1: An integrated device for cigarette weight control and quality inspection based on IPC cigarette machine, figure 1 Composition block diagram for the principle of the present invention, the present embodiment adopts the IPC system of German BECKHOFF company and its module and EtherCAT bus line to realize the weight control function and the quality detection function of cigarette, by data processing unit, weight control unit IO module, quality detection Unit IO module, pre-signal processing unit, air source stabilization unit, human-machine interface and communication unit, weight control unit IO module and quality inspection unit IO module collect data related to cigarette weight control and quality inspection, and these data are passed through EtherCAT The bus protocol is sent to the data processing unit, and the data is calculated and processed, and the results are sent to the IO module of the weight control unit and the IO module of the quality inspection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com