Roll paper extracting device

A roll paper and paper pumping technology, which is applied in the field of paper pumping devices and roll paper pumping devices, can solve the problems of complex installation and assembly process, low assembly efficiency, and large maintenance, so as to improve the performance and user experience, Effects of improving assembly efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

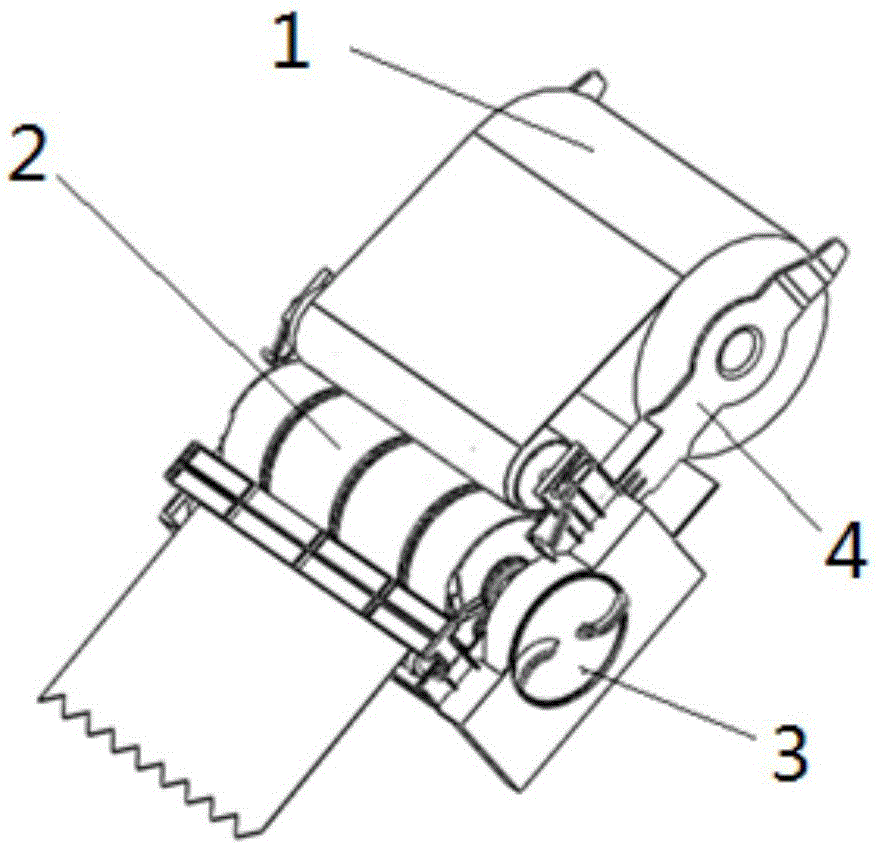

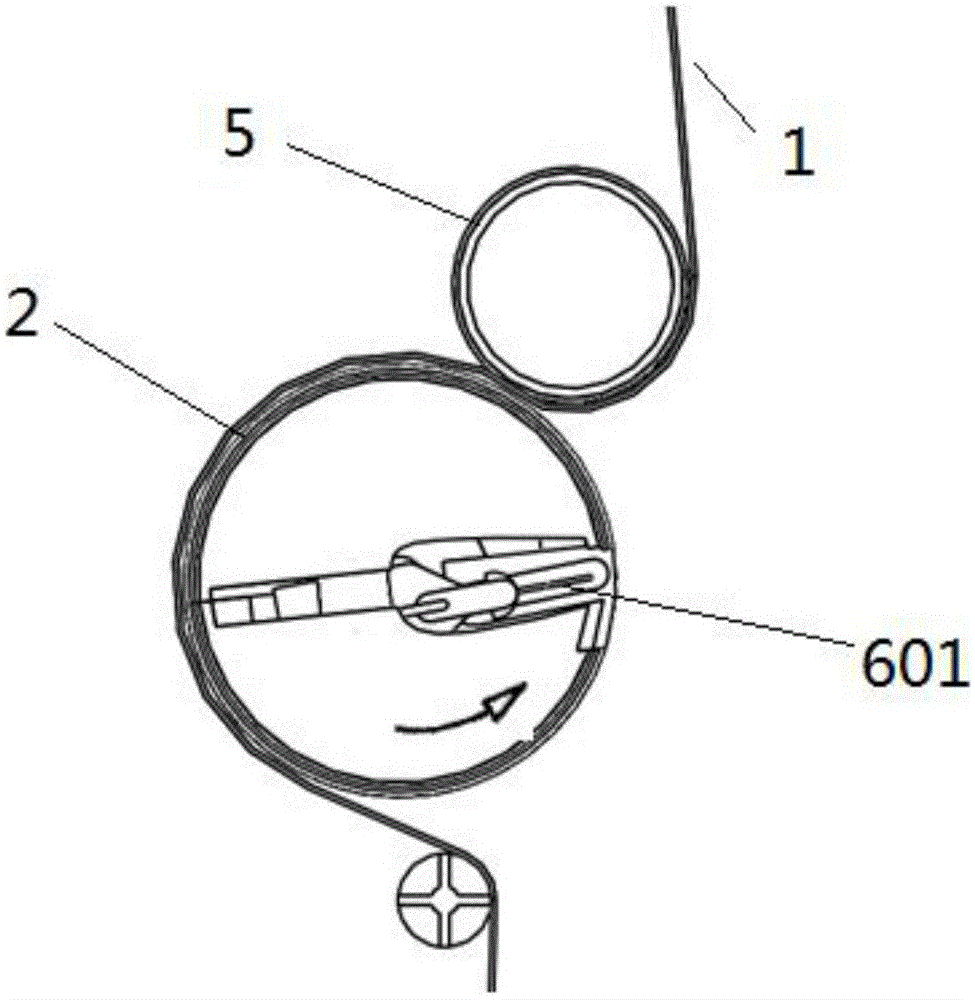

[0037] see figure 1 The support arm 4 is fixed on the frame 8, and the roll paper 1 is installed on the support arm 4. The roll paper 1 passes through the gap between the final shaft 5 and the drum 2. When the end of the roll paper is pulled by an external force, the roll paper will rub against Under the action of force, the pinch 5 provides enough friction by pressing the paper so that the paper can be cut better.

[0038] see figure 1 , the hand wheel 3 is installed on the frame 8, at one end of the wheel drum 2, when the new roll paper is initially installed, the roll paper 1 can be moved in one direction (paper output direction) by rotating the manual 3 wheels.

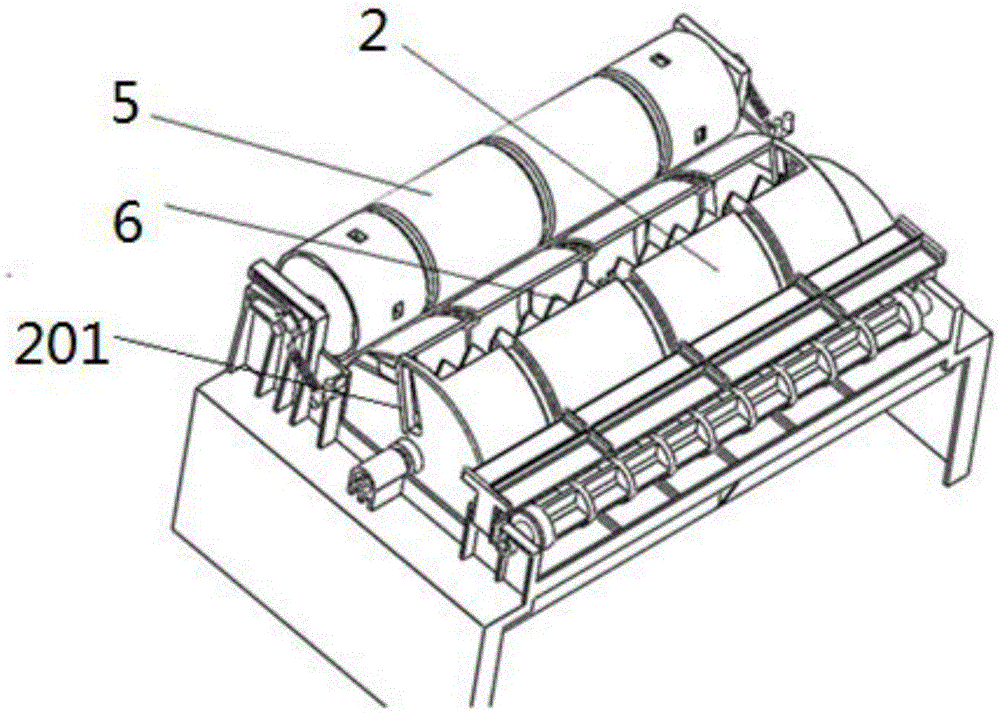

[0039] see Figure 9-Figure 12 , the main shaft portion 701 of the eccentric shaft is fixed with the support, and the central hole of the wheel drum 2 is installed on the main s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap