Classifying and sorting production line for ABS and PP plastic fragments or particles

A technology of plastic fragments and production lines, applied in solid separation and other directions, can solve the problems of large price difference and low economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

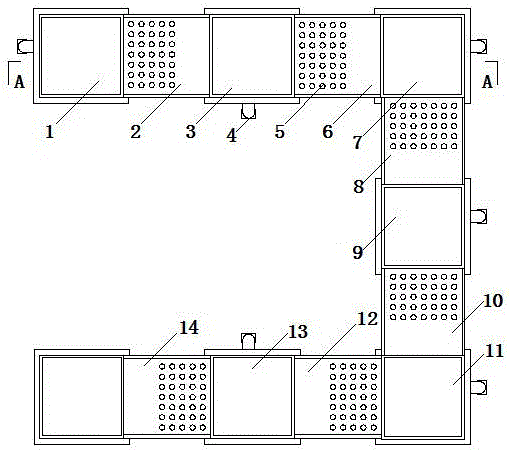

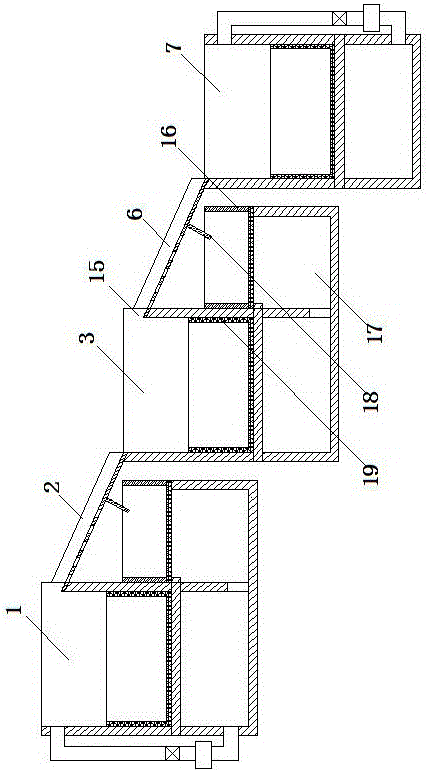

[0026] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0027] Such as figure 1 , figure 2 As shown, the grading and sorting production line of ABS, PP plastic fragments or particles of the present invention includes an ABS sorting device and a PP guide tank 8, and the ABS sorting device includes an ABS sedimentation tank 3, an ABS circulation tank 17 and a pressure pump 4. The top of the ABS deposition tank 3 is open and is provided with an outflow port 15 lower than the open opening. The ABS circulation tank 17 is placed below the ABS deposition tank 3 . The inlet of the pressure pump 4 communicates with the ABS circulation pool 17 , and the outlet communicates with the ABS deposition tank 3 . The ABS deposition pool 3 and the ABS circulation pool 17 are respectively used to contain sodium chloride solution with a concentration of 18%-19.5%. The inlet end of the PP guide groove 8 is provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com