Method for casting bearing cap on subway locomotive by using sand faced permanent iron molding technology

A sand-covered iron mold and bearing cover technology, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of slow cooling speed of castings, non-dense internal structure, large machining allowance of castings, etc., and achieve stable production process , compact internal structure and reduced machining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for casting an upper bearing cap of a subway locomotive by adopting an iron mold sand-covering process, comprising the following steps:

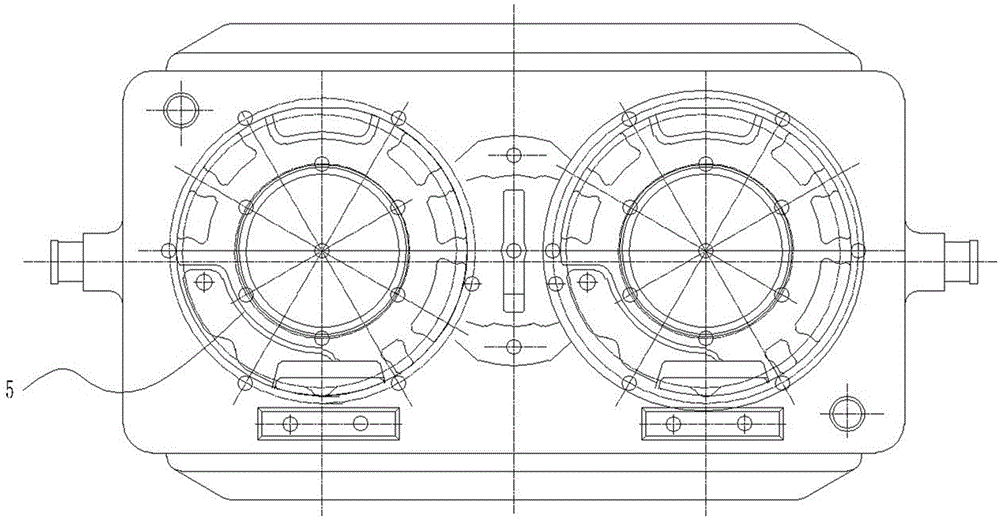

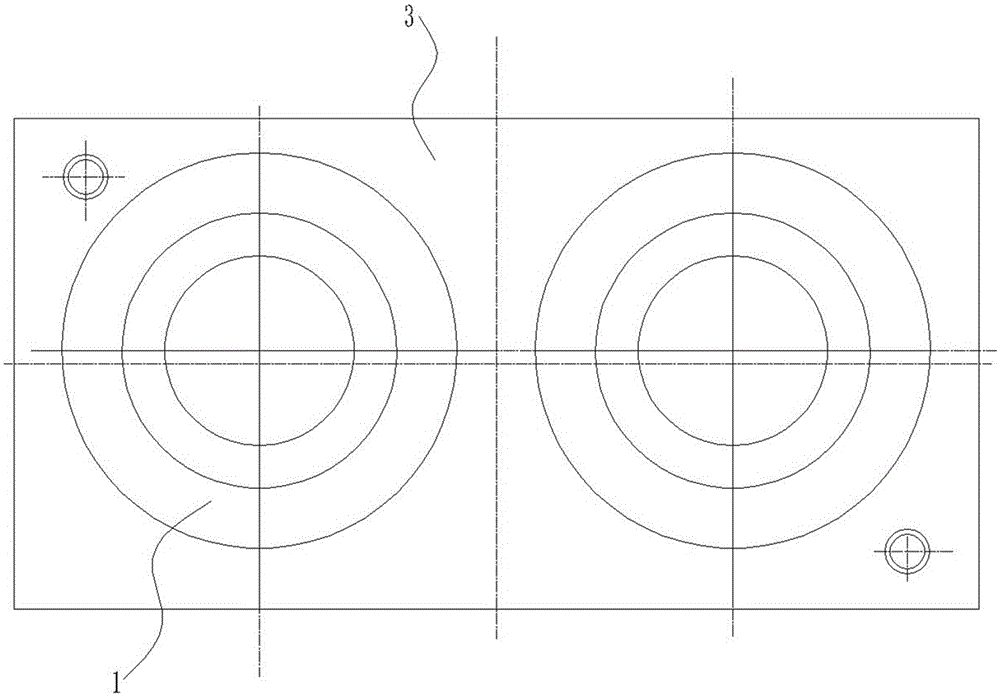

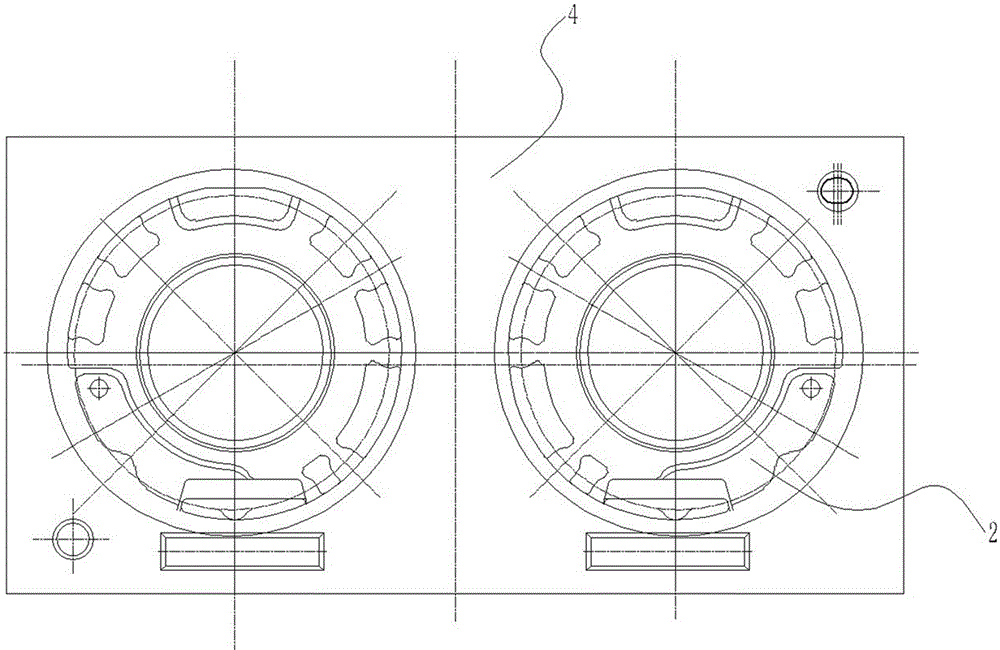

[0039] (1) Design and manufacture a set of upper and lower models that are completely consistent with the shape of the upper bearing cap of the subway locomotive as a master mold. The master mold includes the designed and manufactured bearing cap tooling mold, core box, pouring system, heating plate and base. Such as figure 2 , image 3 , Figure 6-9 As shown, the upper mold 1 is fixed on the upper mold plate 3, and the lower mold 2 is fixed on the lower mold plate 4. Two upper molds 1 are arranged side by side on the upper mold plate 3, and two upper molds 1 are arranged side by side on the lower mold plate 4. Two lower models 2, which can improve the efficiency of machining castings. The upper mold plate 3 and the lower mold plate 4 are respectively provided with exhaust valves for exhausting, so as to facilitate the di...

Embodiment 2

[0042] A method for casting an upper bearing cap of a subway locomotive by adopting an iron mold sand-covering process, comprising the following steps:

[0043] (1) Design and manufacture a set of upper and lower models that are completely consistent with the shape of the upper bearing cap of the subway locomotive as a master mold. The master mold includes the designed and manufactured bearing cap tooling mold, core box, pouring system, heating plate and base. Such as figure 2 , image 3 , Figure 6-9 As shown, the upper mold 1 is fixed on the upper mold plate 3, and the lower mold 2 is fixed on the lower mold plate 4. Two upper molds 1 are arranged side by side on the upper mold plate 3, and two upper molds 1 are arranged side by side on the lower mold plate 4. Two lower models 2, which can improve the efficiency of machining castings. The upper mold plate 3 and the lower mold plate 4 are respectively provided with exhaust valves for exhausting, so as to facilitate the di...

Embodiment 3

[0046] A method for casting an upper bearing cap of a subway locomotive by adopting an iron mold sand-covering process, comprising the following steps:

[0047] (1) Design and manufacture a set of upper and lower models that are completely consistent with the shape of the upper bearing cap of the subway locomotive as a master mold. The master mold includes the designed and manufactured bearing cap tooling mold, core box, pouring system, heating plate and base. Such as figure 2 , image 3 , Figure 6-9 As shown, the upper mold 1 is fixed on the upper mold plate 3, and the lower mold 2 is fixed on the lower mold plate 4. Two upper molds 1 are arranged side by side on the upper mold plate 3, and two upper molds 1 are arranged side by side on the lower mold plate 4. Two lower models 2, which can improve the efficiency of machining castings. The upper mold plate 3 and the lower mold plate 4 are respectively provided with exhaust valves for exhausting, so as to facilitate the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com