Multi-axis sawing machine with sawing paths and sawing angles adjustable

A sawing machine and angle adjustment technology, which is applied to metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve problems such as poor precision, low efficiency of sawing machines, and the inability to change the speed of saw blades, etc., to achieve improved Utilization rate, reduced mold change and adjustment time, and the effect of avoiding disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

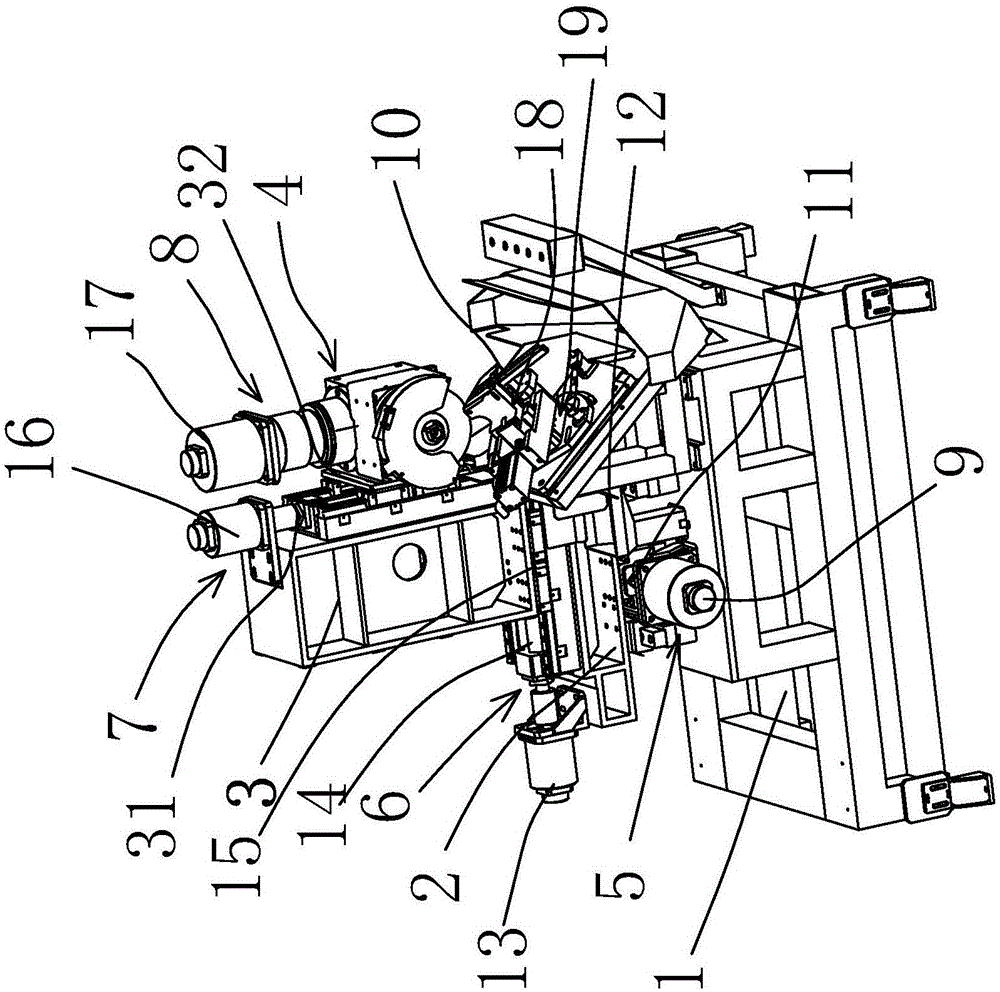

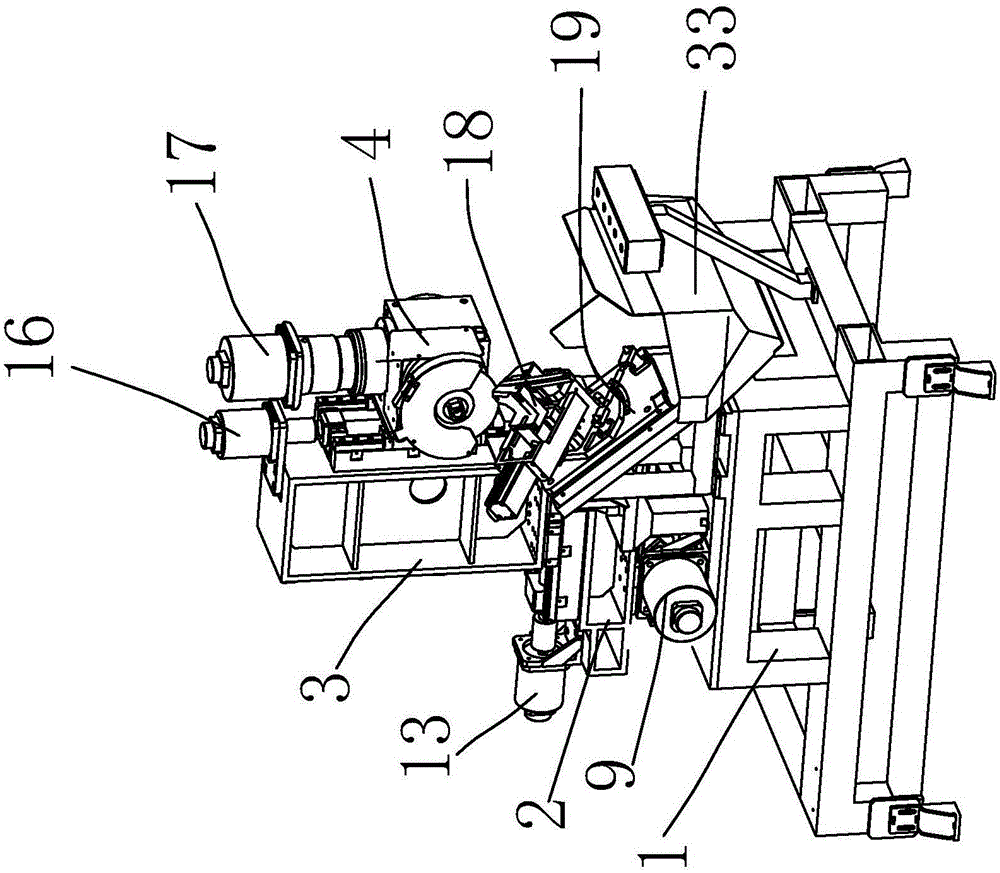

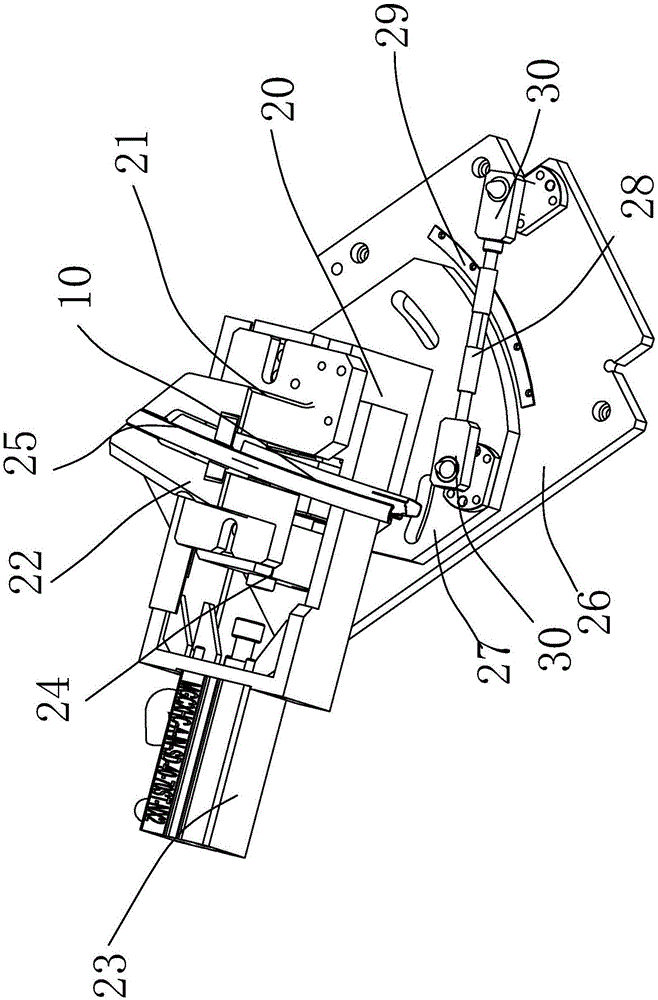

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0019] In the figure, the main frame 1; the main moving frame 2; the upper moving frame 3; the sawing mechanism 4; the first driving mechanism 5; the second driving mechanism 6; the third driving mechanism 7; the fourth driving mechanism 8; the first servo motor 9; product 10; first driving screw 11; first connecting sliding block 12; second servo motor 13; second driving screw 14; second connecting sliding block 15; third servo motor 16; fourth servo motor 17 ; product fixing mechanism 18; angle adjustable assembly 19; main fixed seat 20; positioning block 21; movable block 22; driving cylinder 23; driving block 24; fixed space 25; 28 ; guide limiter 29 ; adjustment distance fitting 30 ; third driving screw 31 ; third con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com