An electromagnetically driven adaptive carbon ribbon printing mechanism

An adaptive, electromagnetic-driven technology, applied in printing, transfer materials, power transmission devices, etc., can solve the problems of poor printing effect and complex structure, and achieve the effect of simple structure, convenient adjustment and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

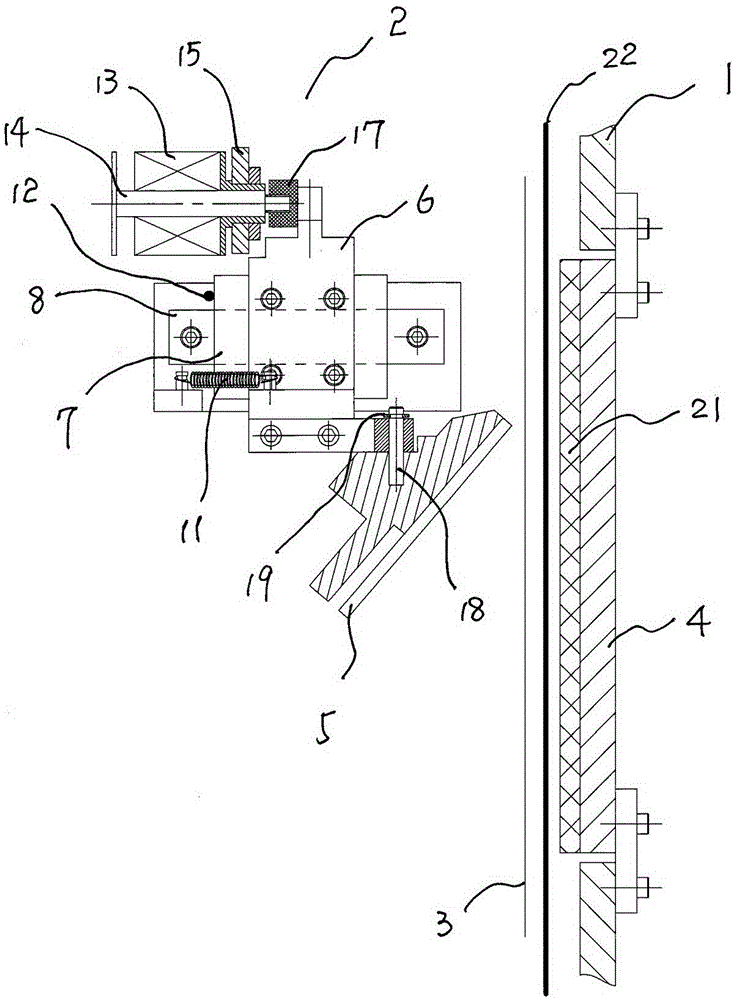

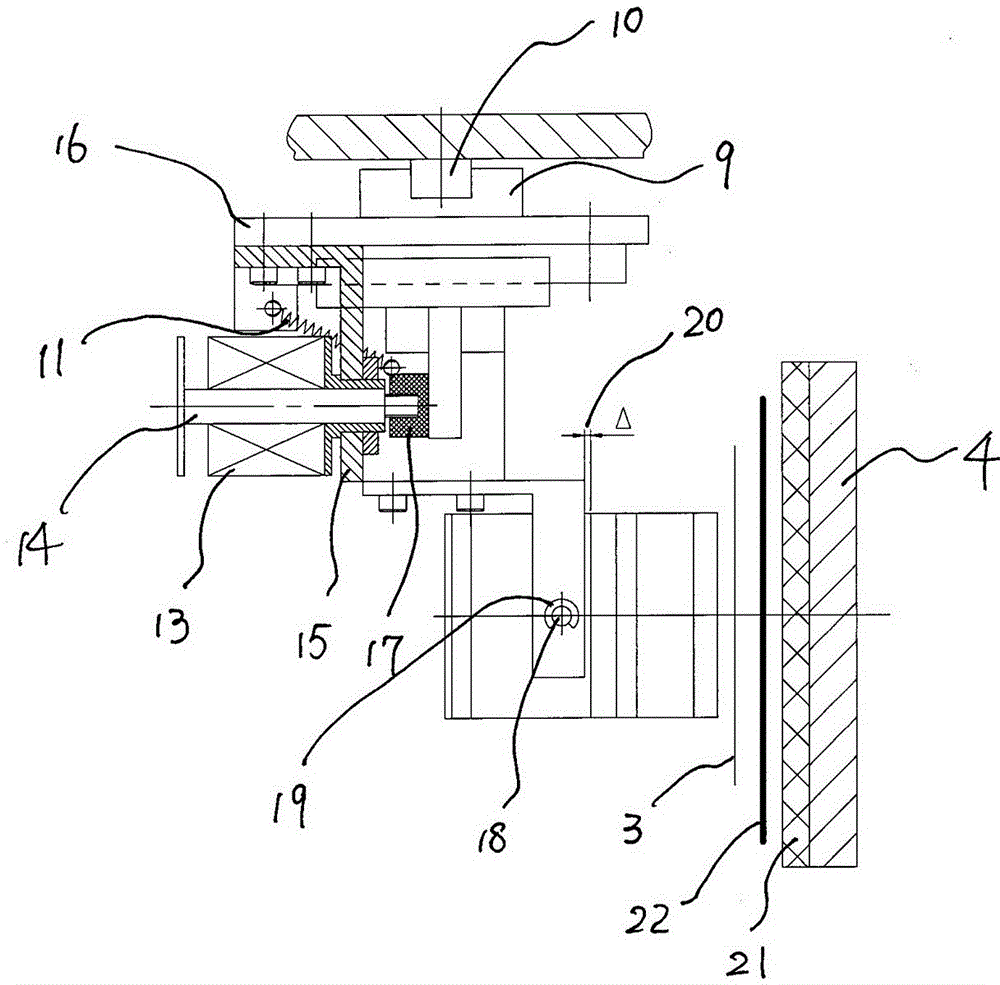

[0011] As shown in the figure, the present invention includes a frame 1, a printer assembly 2, a carbon ribbon 3 and a backing plate 4, the printer assembly 2 is arranged on one side of the frame 1, the backing plate 4 is arranged on the other side of the frame 1, and the carbon The belt 3 is located between the printer assembly 2 and the backing plate 4. In the printer assembly 2, the mounting bracket 6 of the print head 5 is fixedly connected to the slider 7, and the slider 7 is slidably matched with the horizontal guide rail 8. The width direction is perpendicular, the horizontal guide rail 8 is fixedly connected to the vertical slide seat 9, the vertical slide seat 9 is slidably matched with the vertical guide rail 10, the mounting bracket 6 is driven by the horizontal drive mechanism, reset by the elastic reset member 11, and fixedly connected to the The limit bumper 12 on the vertical slide 9 is limited, and the horizontal drive mechanism is composed of an electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com