Paper cup packaging machine

A packaging machine and paper cup technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of speed mismatch, high packaging cost, material waste, etc., achieve efficient packaging, save material consumption, and reduce packaging costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below by specific examples:

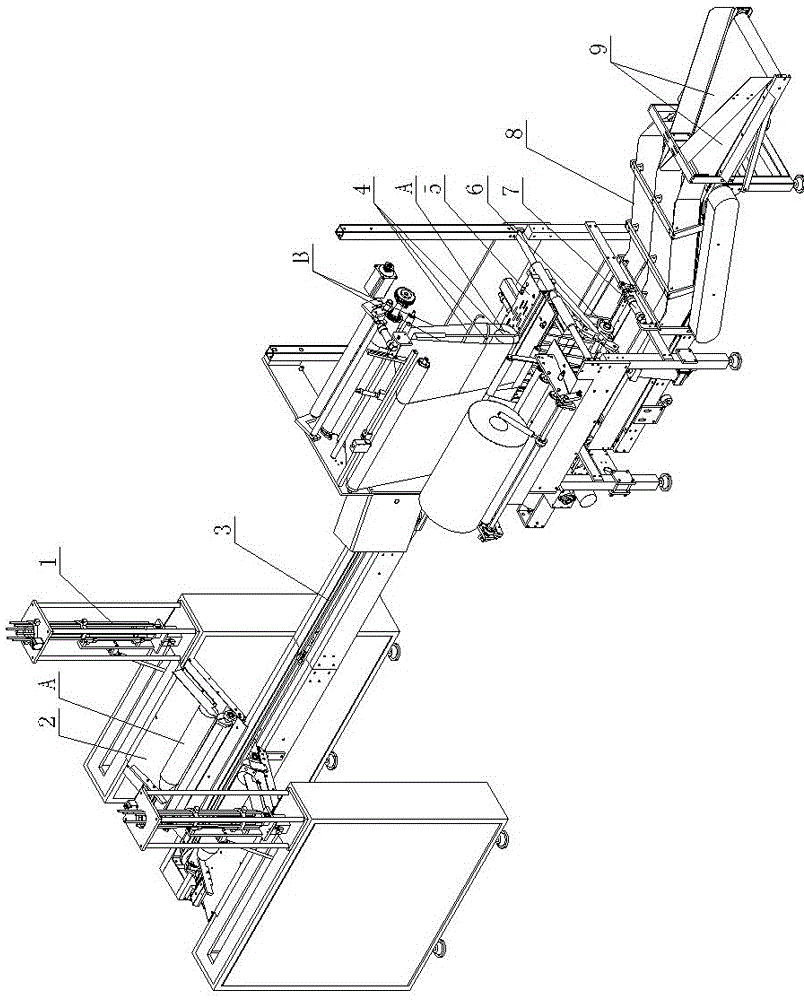

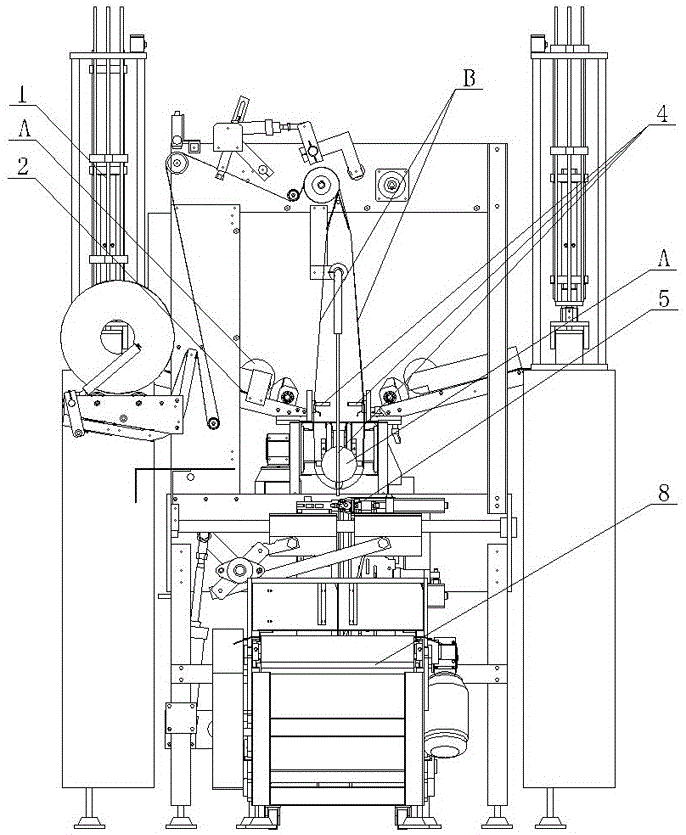

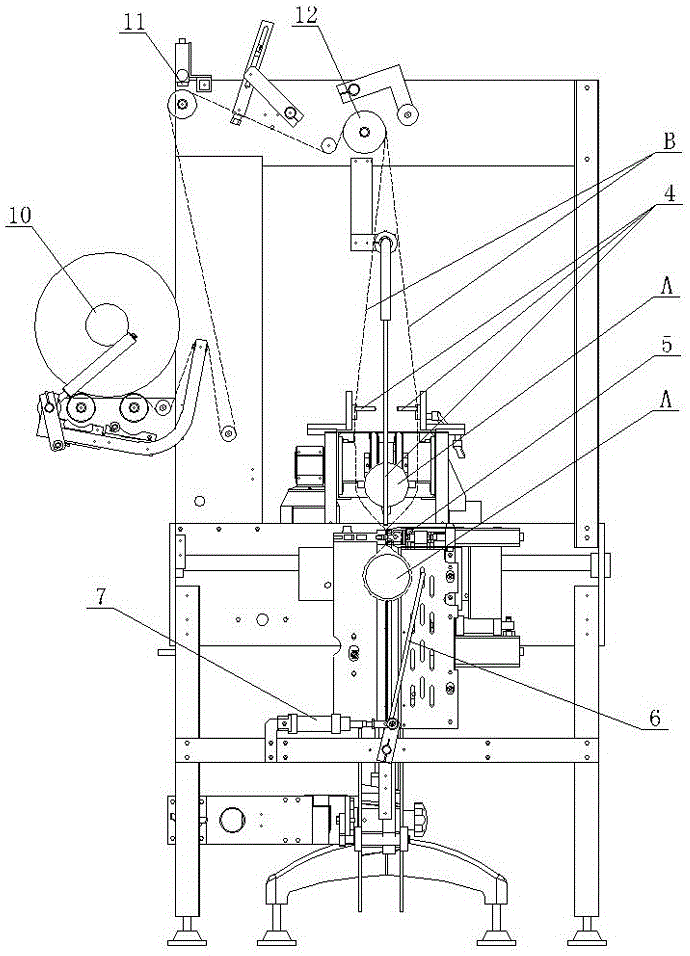

[0020] As shown in the figure, the paper cup packaging machine of the present invention includes a cup and barrel conveying platform 3, and a plurality of independently arranged cup pointing racks 1 are arranged on both sides of the cup and barrel conveying platform 3, and the cup pointing racks 1 can be turned over and opened, and the specific structure is as follows: : half of the point cup holder is an active setting, and the active half is connected with the cup holder cylinder through a connecting rod. The point cup holder 1 is connected to the cup and barrel conveying platform 3 through the online platform 2. The online platform 2 is equipped with a detection element for detecting the cup and barrel A. The output of the detection element is electrically connected with the packaging machine controller, and the detection element automatically recognizes other online platforms. After confirmin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com