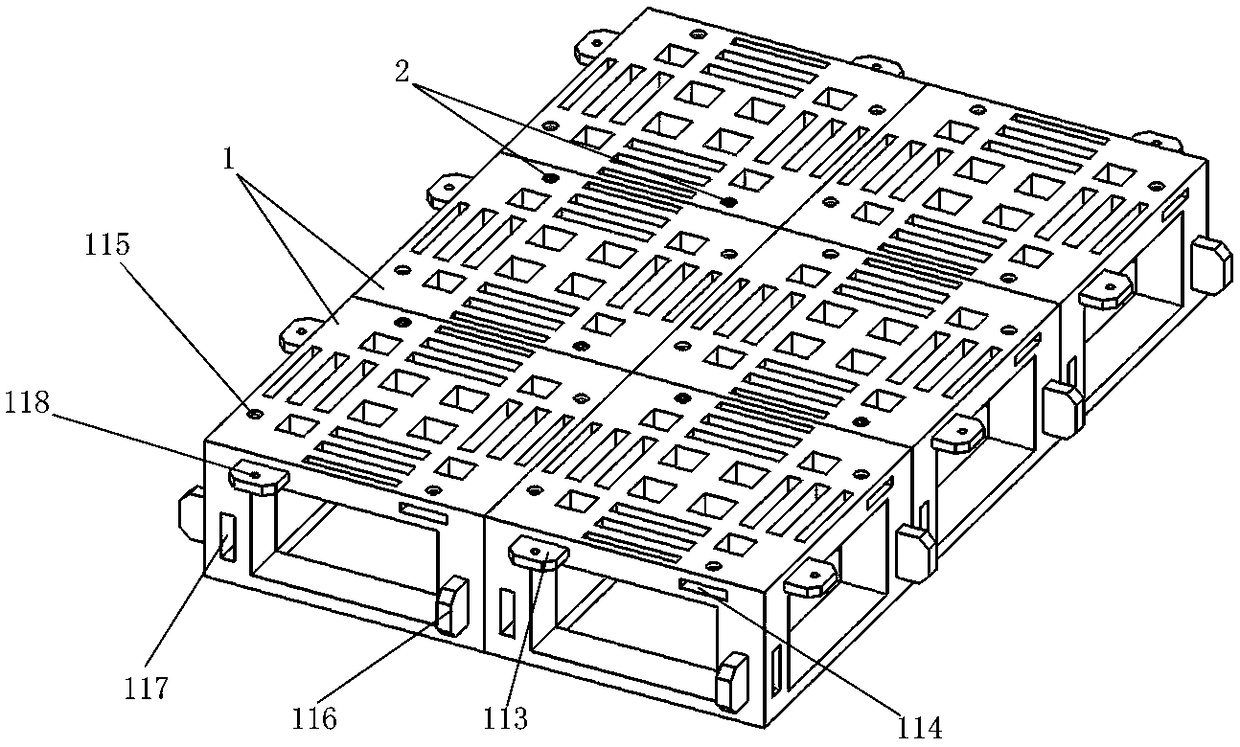

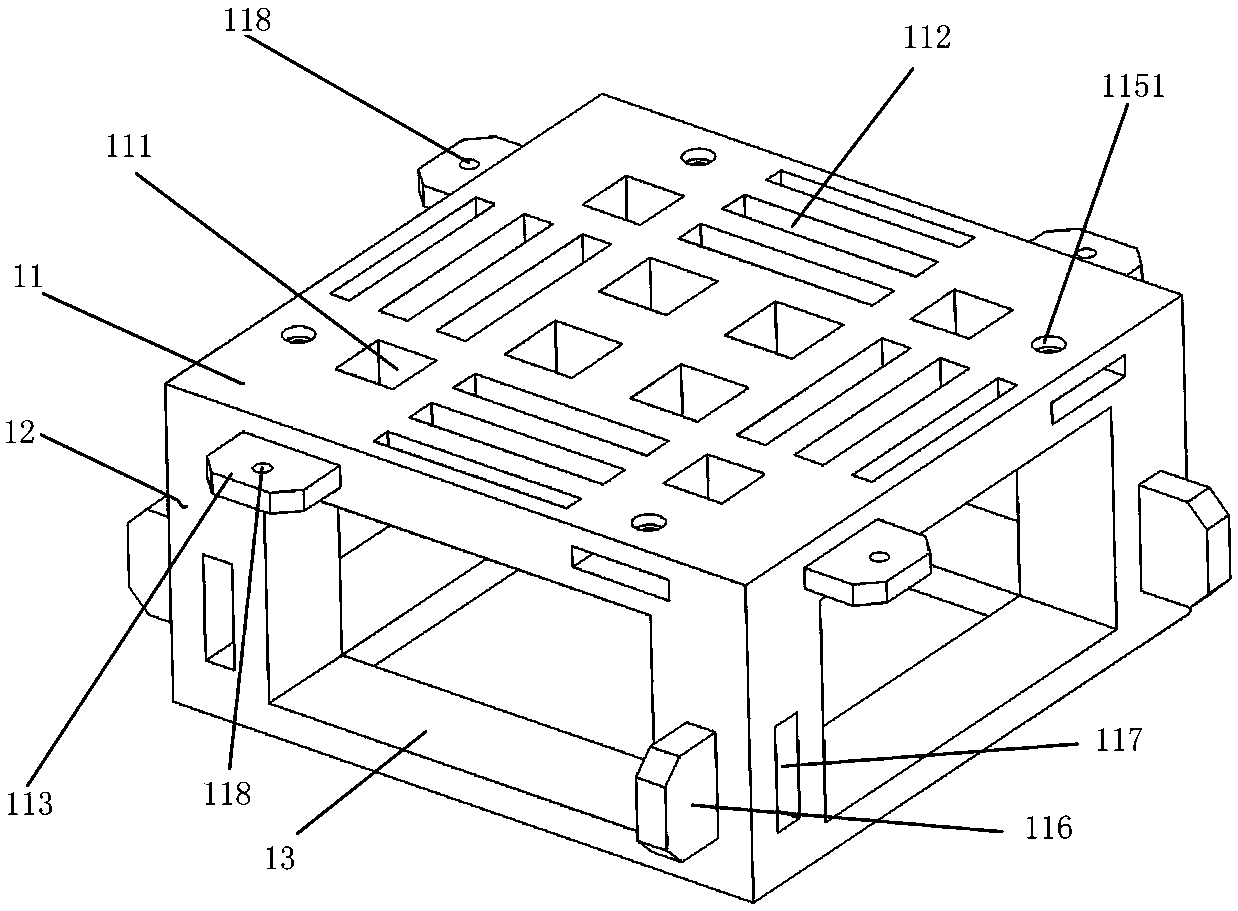

A combined splicable tray and its preparation method

A combination and pallet technology, which is applied in the directions of packaging, transportation, packaging, containers, etc., can solve the problem of protection of pallets and packing belts, the impact resistance of pallet materials, and its own portability and environmental adaptability. Insufficient, poor versatility and reusability, etc., to achieve the effect of small density, small storage and transportation space, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

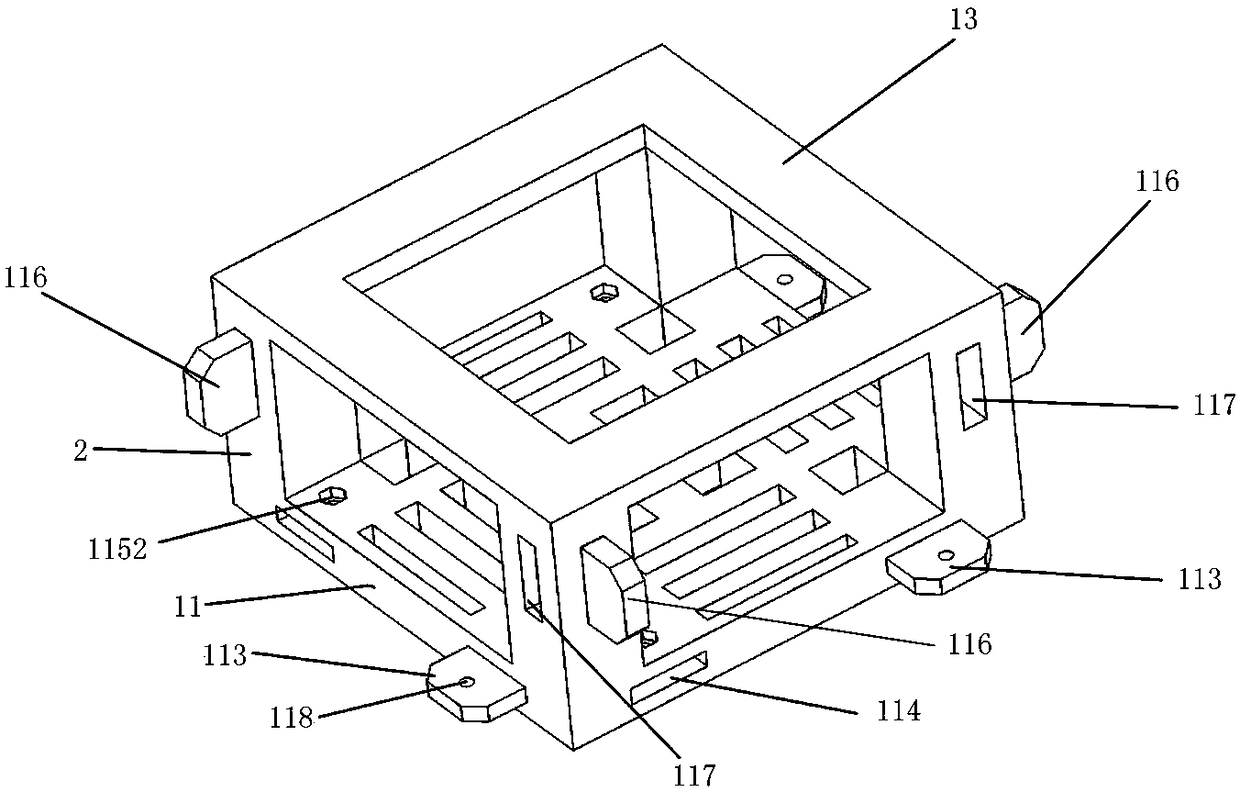

[0034] Structural Example 2: as Image 6 As shown, according to the size of a certain type of ammunition packing box, select 12 pallet units to assemble the pallet unit in a 3×4 array, tighten the connectors, divide the 20 boxes of ammunition into four stacks to prevent the pallet from above, and put the steel packing belt from the pallet unit "Sichuan ” into the middle gap of the font space, tighten and fix, and complete the pallet assembly of a certain type of ammunition.

Embodiment 3

[0035] Structural Example 3: as Figure 7 As shown, according to the size of a certain type of ammunition packing box, select 9 pallet units to assemble the pallet unit in a 3×3 array, tighten the connectors, place 8 boxes of ammunition in two stacks on the pallet, and put the steel packing belt from the pallet unit "Sichuan "" is penetrated into the outer space of the space, tightened and fixed, and the pallet assembly of a certain type of ammunition is completed.

[0036] Structural Example 4: as Figure 8 As shown, according to the size of a certain type of ammunition packing box, select 12 pallet units to assemble the pallet unit in a 3×4 array, tighten the connectors, place 8 boxes of ammunition in two stacks on the pallet, and attach the self-tightening fastening belt from the pallet unit. The outer side penetrates, packs firmly, and completes the pallet assembly of a certain type of ammunition.

[0037] Structural Example 5: as Figure 9 As shown, according to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com