Automatic label crimper

A label roll and automatic technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of loose rolls, confusing labels, inconvenient use, etc., and achieve simple and effective structure, convenient operation and finishing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

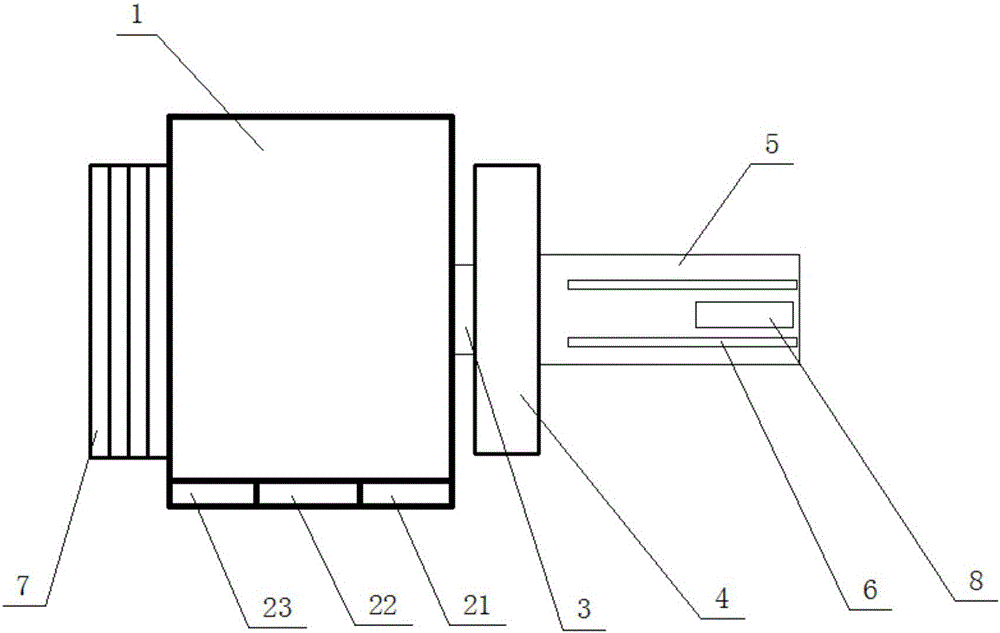

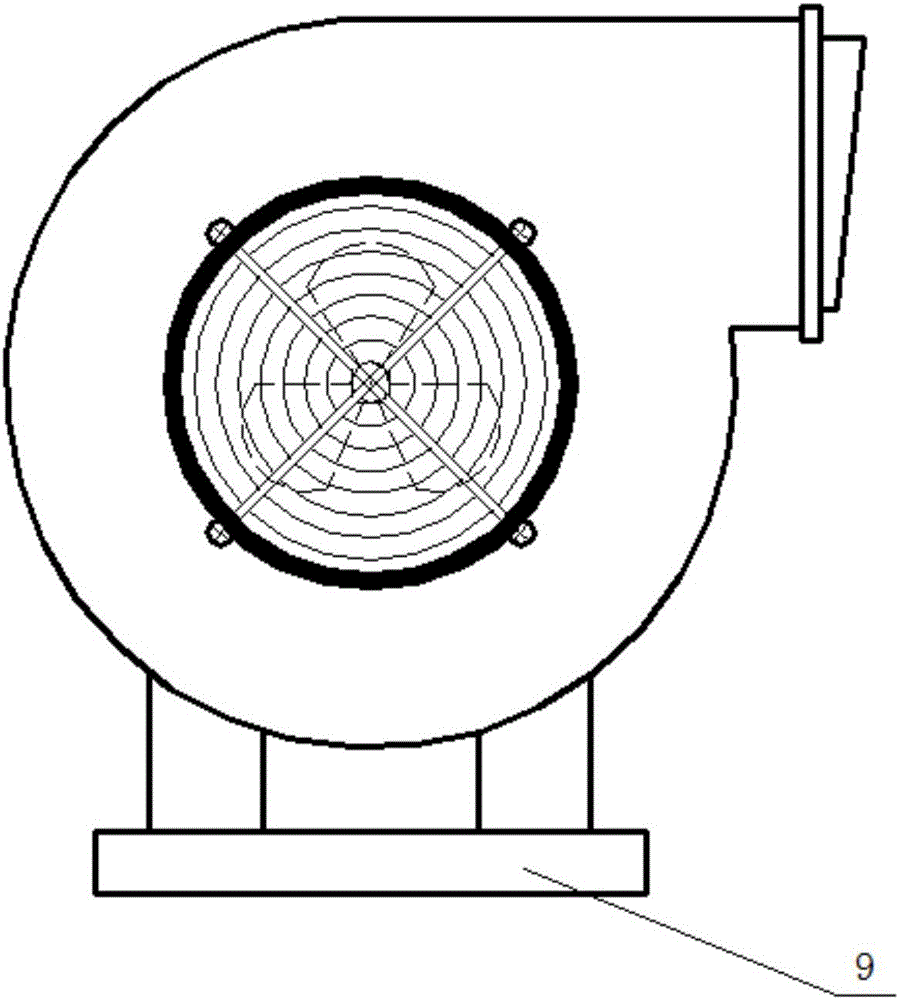

[0017] refer to figure 1 with figure 2 As shown, an automatic label reel machine includes a reel machine body 1 and a base 9, and also includes a rotating motor arranged in the body 1, the rotating motor is connected with the label reel 5 through a connecting bearing 3, and the label reel A baffle 4 is arranged on the side of the cylinder 5 close to the fuselage 1, and a winding tooth 6 and a heating device 8 are also arranged on the label reel 5. The fuselage 1 is provided with a power switch 21 and a heating switch 22, and preset Variable speed switch 23.

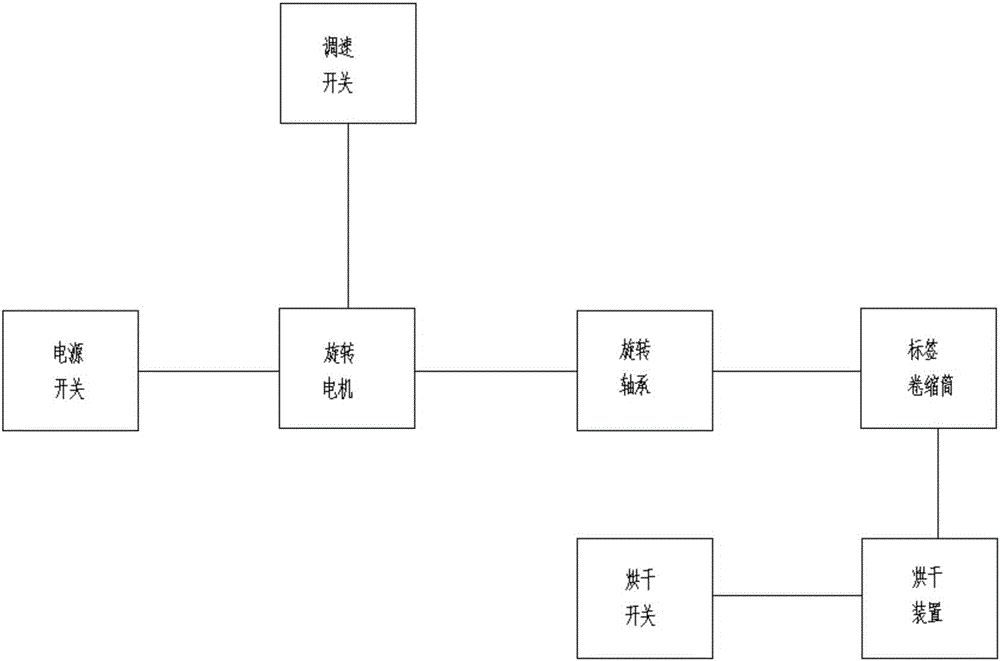

[0018] The connection relationship reference of the internal components of the reel machine adopting the manual adjustment scheme image 3 As shown in , manually adjust the roll speed through the variable speed switch to match the output speed of the printing device.

[0019] Use the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com