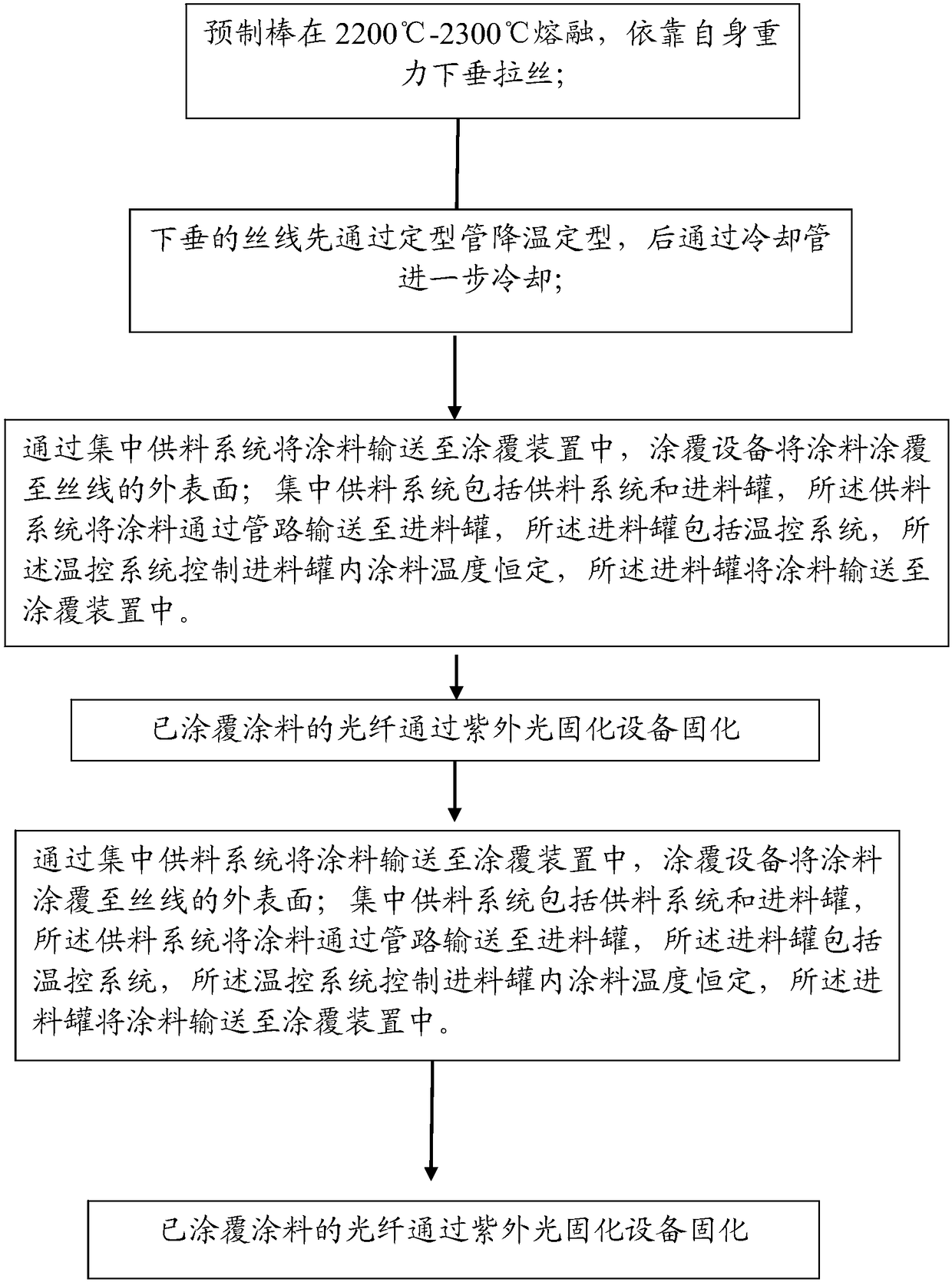

Fiber drawing process

A wire drawing and optical fiber technology, which is applied in the field of optical fiber production, can solve the problems of high operational risk and error-prone, high labor intensity, and difficulty in guaranteeing the temperature of the coating material. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

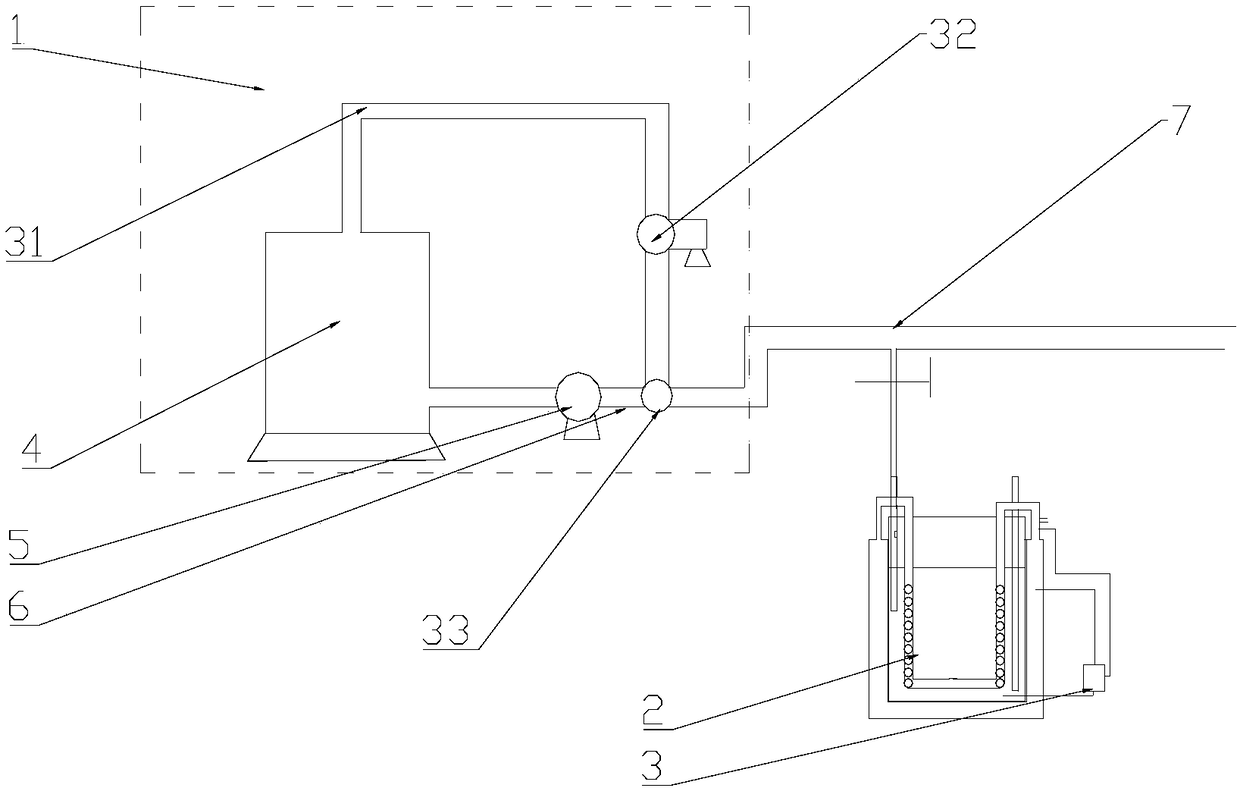

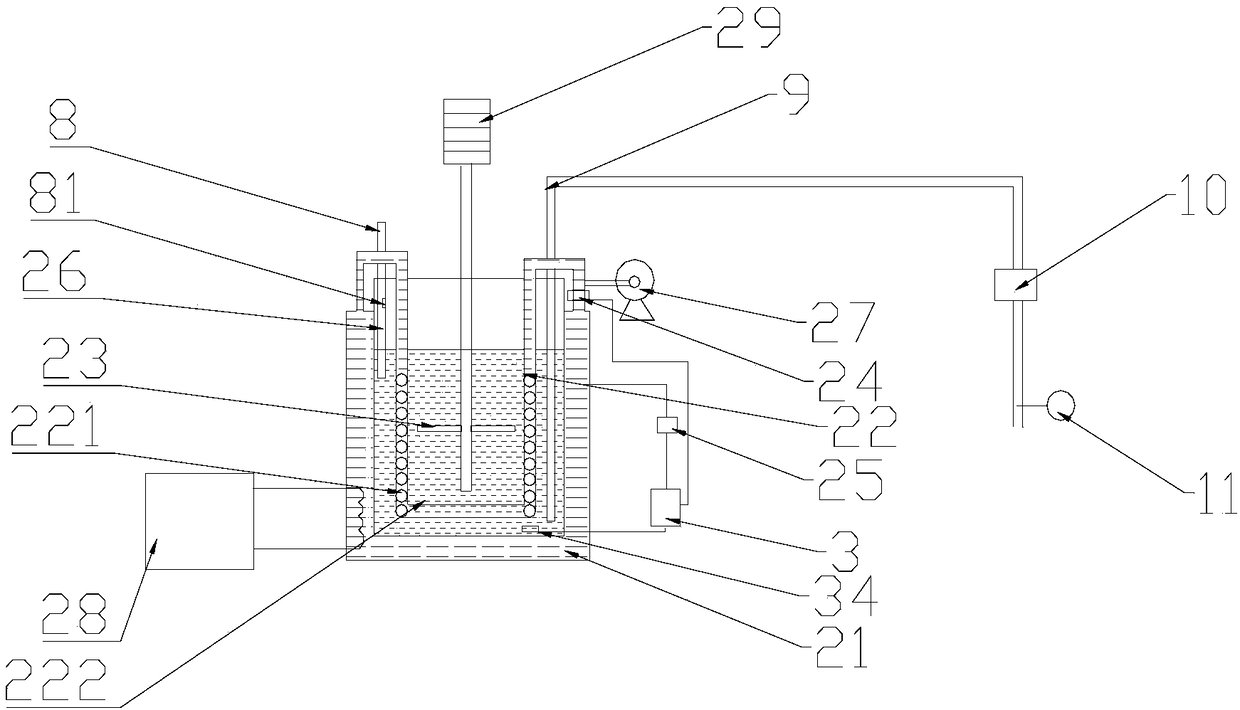

[0038] Embodiment: The embodiment of the present invention discloses a kind of centralized feeding system (see attached figure 2 , 3, 4), can be applied in above-mentioned step 3) and step 5), described centralized feeding system comprises feeding system 1 and feed tank 2, and described feeding system will 1 paint be delivered to feed through pipeline The tank 2, the feed tank 2 includes a temperature control system 3, the temperature control system 3 controls the temperature of the paint in the feed tank 2 to be constant, and the feed tank 2 transports the paint to the coating device. The present invention uniformly supplies and transports the paint by adopting a centralized feeding system, reduces the labor intensity of personnel, and ensures the continuity of production. At the same time, the temperature control system is used to ensure that the temperature of the paint in the feeding tank is constant, and the paint entering the coating device is ensured. The viscosity is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com