A three-dimensional silicon-based micro-nano photonic crystal solar cell

A technology of solar cells and micro-nano photons, applied in the field of solar cells, can solve the problems of surface reflection loss, complex production process, narrow reflection band, etc., to reduce equivalent grid electrode resistance, improve photoelectric conversion efficiency, and strong light trapping ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Line-defect waveguide with triangular lattice arrangement

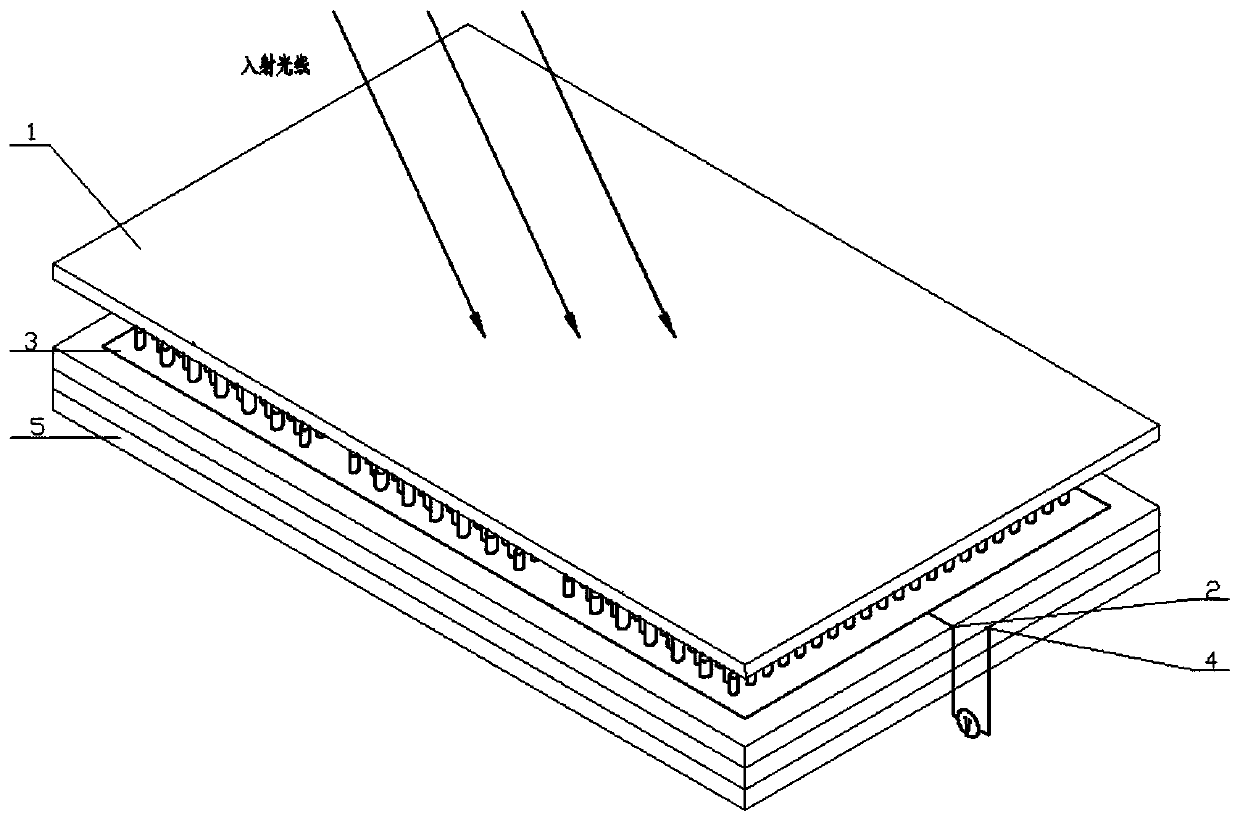

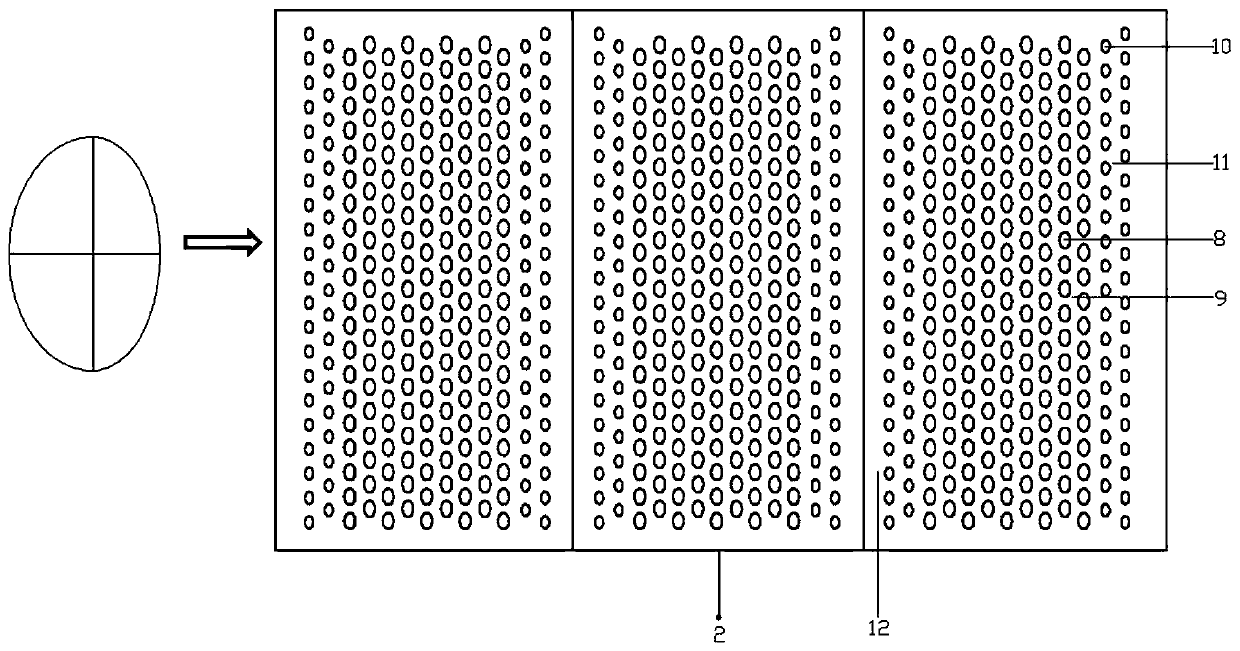

[0039] The overall structure of this embodiment is as figure 1 As shown, FIG. 2 is a schematic diagram of the three-dimensional silicon-based micro-nano photonic crystal solar cell structure 3 described in this embodiment, wherein the n-type silicon semiconductor 6 is a structure with a periodic arrangement of two substructures with a forbidden band and a slow light effect:

[0040] (1) Forbidden zone: The forbidden zone scattering element 8 of the n-type silicon semiconductor 6 adopts an asymmetric elliptical scattering element (the long axis of the structure is the same, the short axis is different, e will have 2 different values), and the spatial arrangement is triangular Lattice structure; the central wavelength of forbidden band is set at λ=700nm, can obtain by plane wave expansion method: when the central wavelength of forbidden band is set at 700nm, the lattice constant of n-type silicon semic...

Embodiment 2

[0044] Example 2: Reticulate line defect waveguide arranged in a quadrilateral

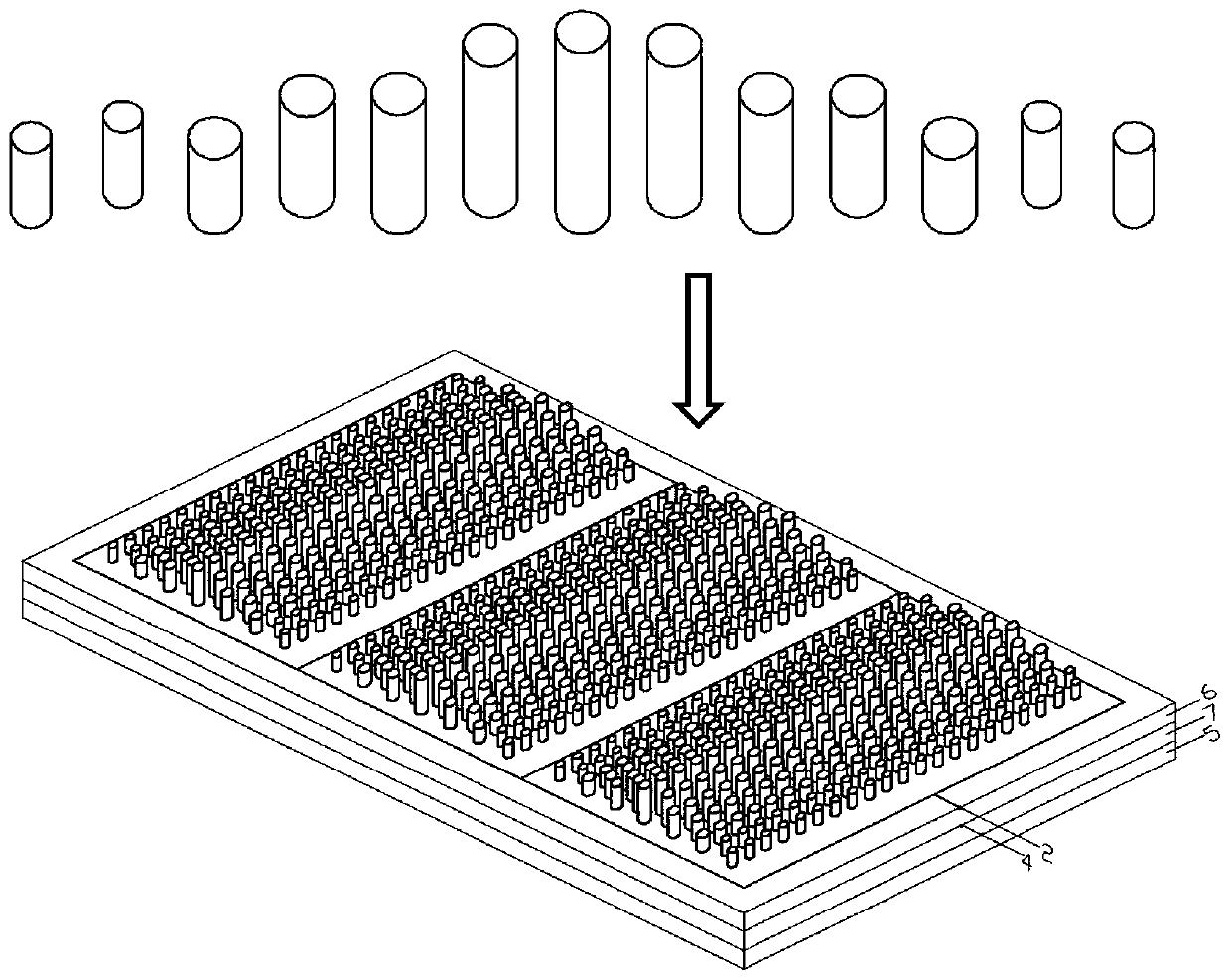

[0045] The overall structure of this embodiment and figure 1 Similarly, Fig. 5 is a schematic diagram of a three-dimensional silicon-based micro-nano photonic crystal solar cell structure 3, wherein the n-type silicon semiconductor 6 is a structure with a periodic arrangement of two substructures with a band gap and a slow light effect:

[0046] (1) band gap: the band gap scattering element 8 of the n-type silicon semiconductor 6 adopts a symmetrical circular bow-shaped scattering element, and the space is arranged as a symmetrical structure of a four-sided lattice; the central wavelength of the band gap is set at λ=700nm, by Plane wave expansion method can obtain: when the central wavelength of forbidden band is set at 700nm, the lattice constant of n-type silicon semiconductor 6 is a=0.29λ, the major axis parameter b=0.40a, e=0.28 of scattering element 8 in forbidden band region ; The height h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com