Lifting systems for structurally asymmetric objects

An asymmetrical, walking system technology, used in cranes, load hanging components, transportation and packaging, etc., can solve the problems of required working headroom, large working height, inability to use, etc., and achieve targeted and avoidable lifting scenarios. Tilt or sway, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

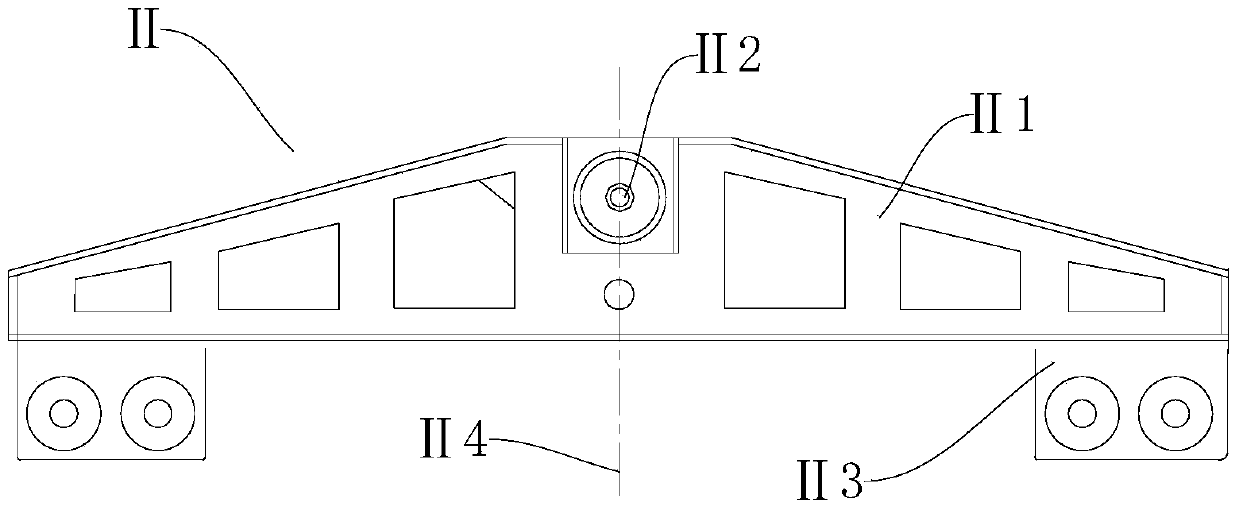

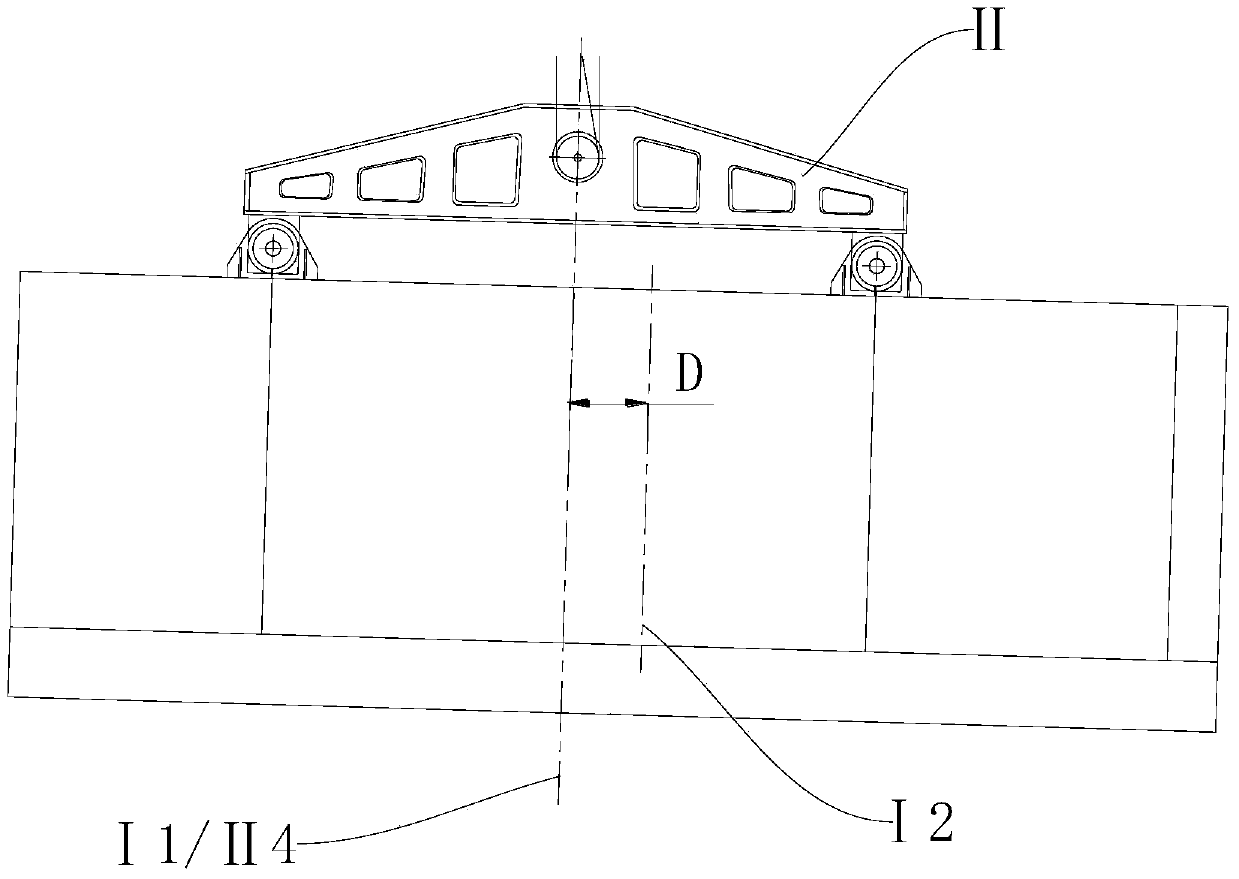

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

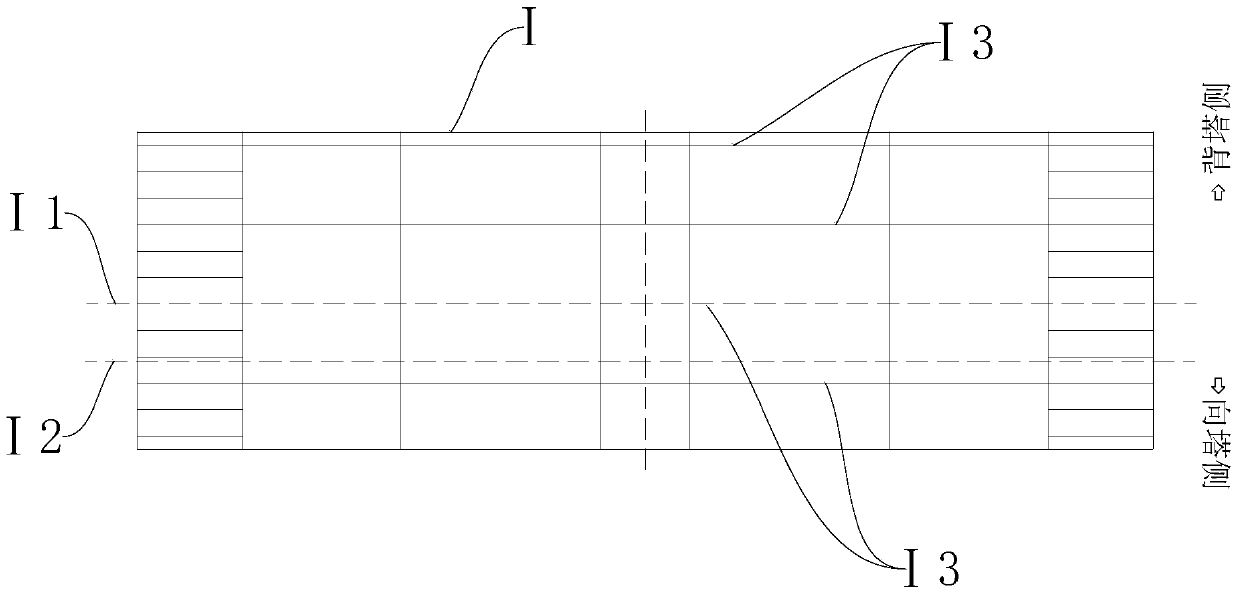

[0039] In this embodiment, a standard steel box girder used for assembling the deck of a cable-stayed bridge or a suspension bridge is taken as an example to describe in detail the lifting system for structural asymmetric objects of the present invention. Such as figure 1 The dimensions of a standard steel box girder I shown are as follows: the height of the center of the steel box girder I is 3.54m, the length is 12m, the thickness of the top plate is 16mm and 32mm (at the anchor plate), the thickness of the inclined web is 12mm, and the thickness of the bottom plate is 12mm and The thickness of the U-shaped ribs on the top plate is 8mm, and the thickness of the U-shaped ribs on the bottom plate is 6mm.

[0040] What needs to be explained here is that since the steel box girder I needs to be along the direction of the bridge (ie fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com