Water-saving wine cooler

A water pipe and water outlet technology, which is applied in the field of water-saving wine coolers, can solve the problems of water waste and poor heat exchange effect, and achieve the effects of high heating and cooling efficiency, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

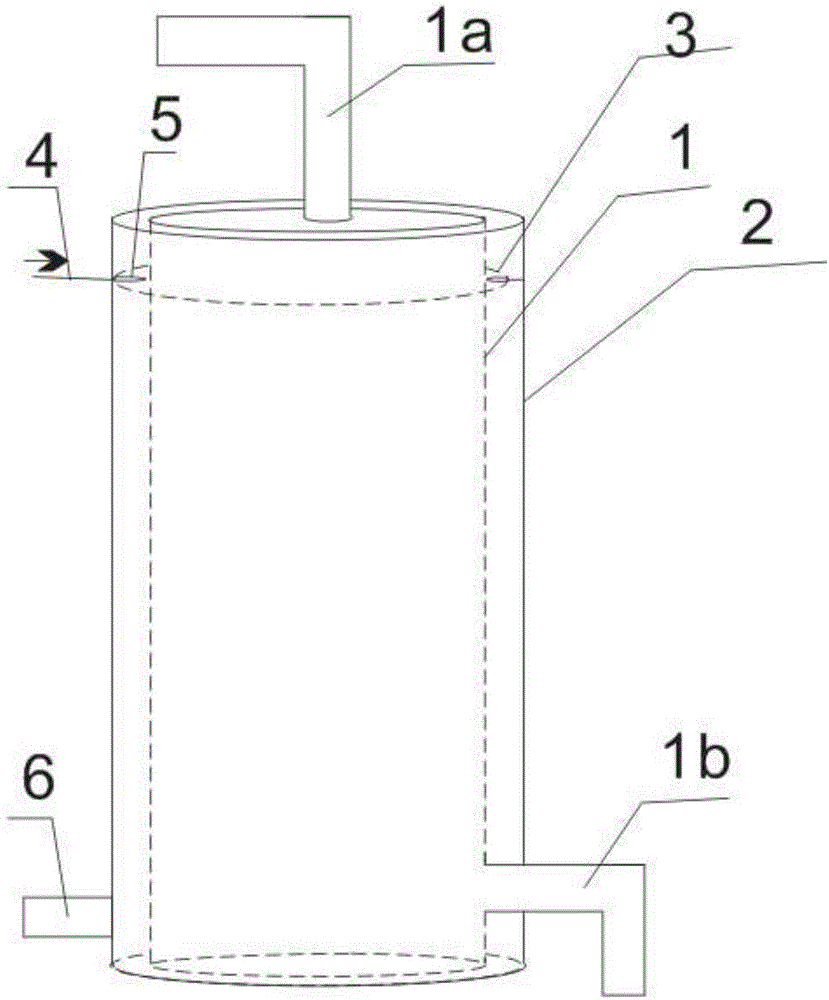

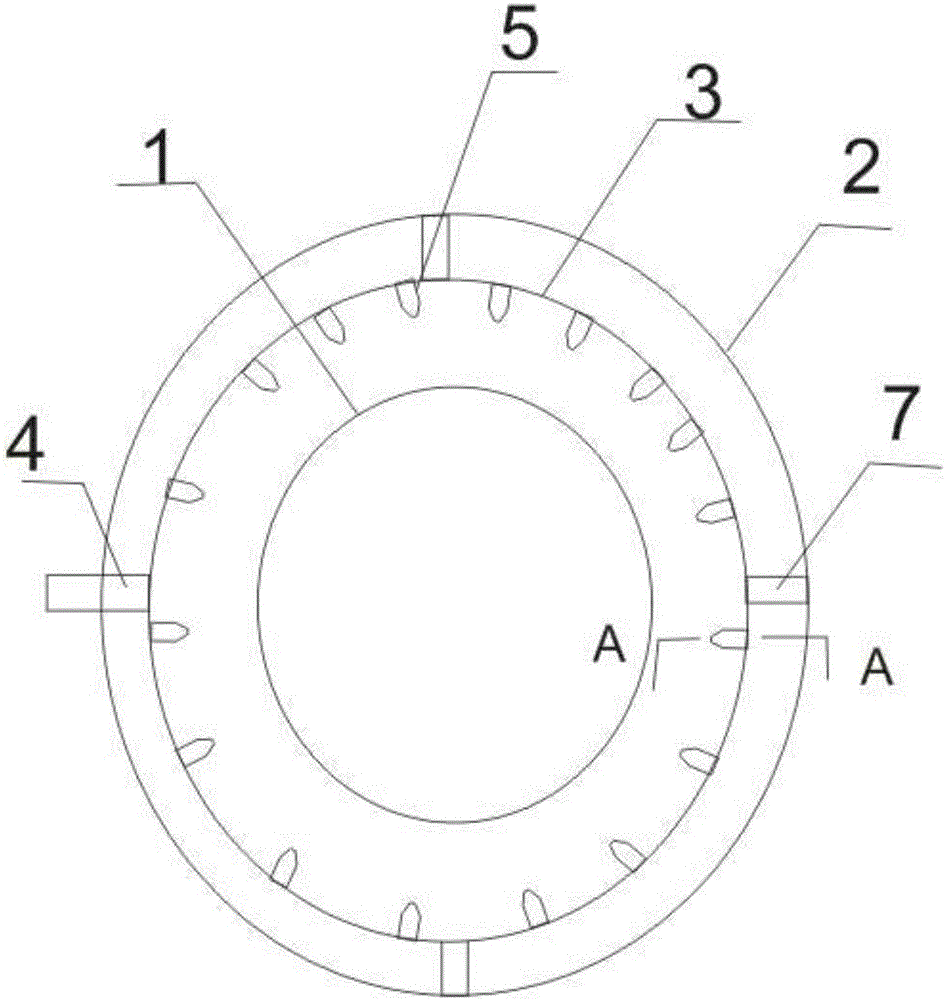

[0016] Example 1, such as Figure 1-3 Shown: the water-saving wine cooler of the present invention is composed of an inner cylinder 1, a jacket 2, an annular cooling water pipe 3, a water inlet pipe 4, a nozzle 5, a water outlet 6, a bracket 7 and other components.

[0017] The inner cylinder 1 is covered with a jacket 2. The jacket 2 is also cylindrical and has a distance from the inner cylinder 1. The top of the inner cylinder 1 is provided with a wine steam inlet 1a, and the bottom is provided with a wine outlet pipe 1b. This is the prior art and will not be repeated here. The inner cylinder 1 and the jacket 2 are made of food grade stainless steel. Ensure food safety.

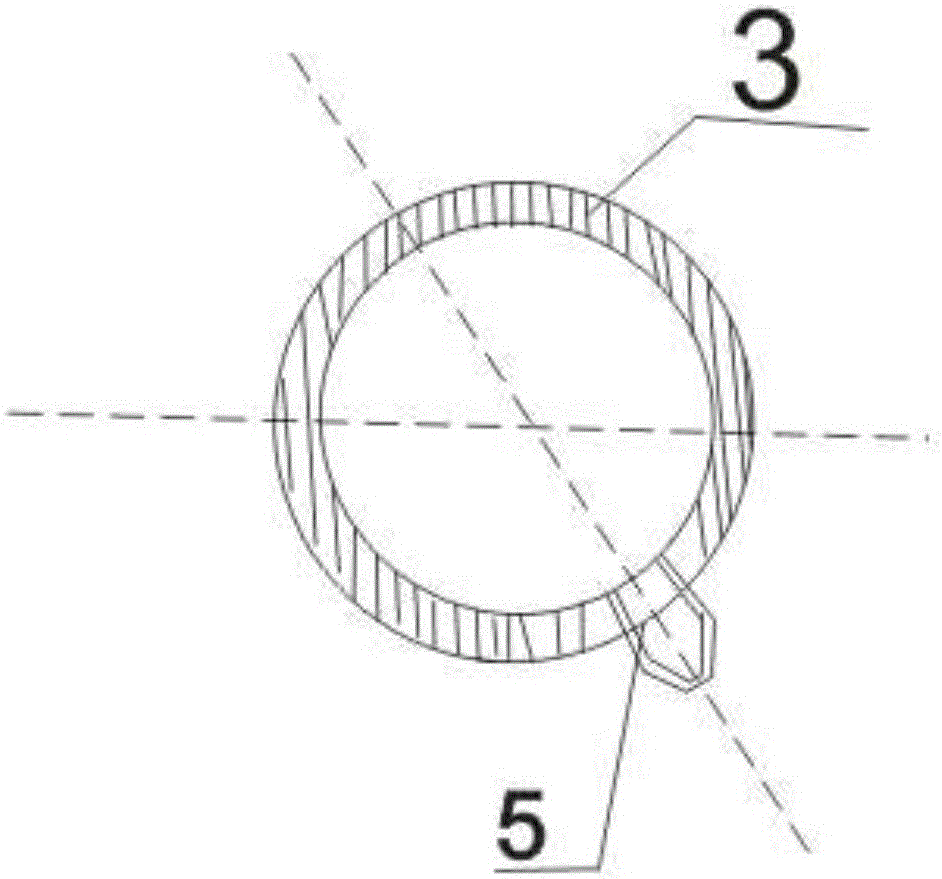

[0018] The upper part of the jacket 2 is provided with an annular cooling water pipe 3, the inner cylinder 1 is located in the annular cooling water pipe 3, the annular cooling water pipe 3 is installed on the inner wall of the jacket 2 through a bracket 7, and the jacket 2 A water inlet pipe 4 communicating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com