A method for increasing nitrogen by blowing nitrogen at the bottom of a ladle

A bottom blowing nitrogen and ladle technology, applied in the field of alloy smelting, can solve the problems of difficult selection of nitrogen and argon switching points, low end point hit rate, complicated operation, etc., to avoid low nitrogen increase control accuracy, avoid high costs, and save the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: The method of blowing nitrogen at the bottom of the ladle to increase nitrogen adopts the following specific process.

[0055] The composition of nitrogen-containing steel is shown in Table 1, and the balance is Fe and unavoidable impurities.

[0056] Table 1: Composition (wt%) of nitrogen-containing steel

[0057] element C Si mn S Cr Al Ni content 0.19 0.09 1.32 0.023 1.20 0.027 0.007

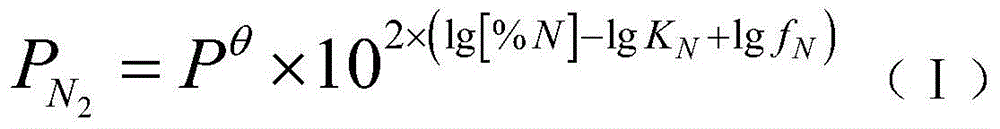

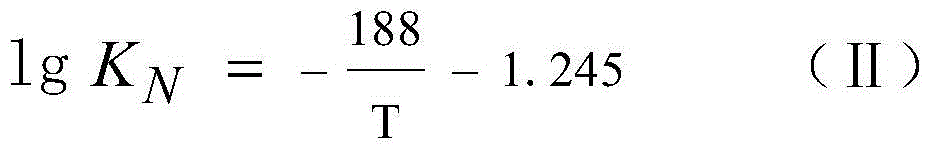

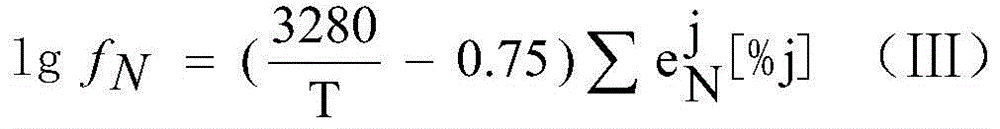

[0058] Calculate according to the above formulas (I), (II), (III) and the ingredients in Table 1. The calculation process is shown in formulas (1-1), (1-2), (1-3):

[0059]

[0060] The depth of molten steel is 2.8m, P 压损 Generally 0.4MPa, then:

[0061] P 总 =1.2(ρ 钢 gh+P 压损 )=0.73MPa (1-2)

[0062] P Ar =P 总 -P N2 =0.7181MPa (1-3)

[0063] Adjust the pressure of nitrogen and argon to the above calculated values as required, and set the flow rate to 200Nl / min for bottom blowing nitrogen alloying; the quality of nitrogen i...

Embodiment 2

[0064] Embodiment 2: The method of blowing nitrogen at the bottom of the ladle to increase nitrogen adopts the following specific process.

[0065]The composition of nitrogen-containing steel is shown in Table 2, and the balance is Fe and unavoidable impurities.

[0066] Table 2: Composition (wt%) of nitrogen-containing steel

[0067] element C Si mn S Cr Al Ni Mo content 0.20 0.22 0.8 0.02 0.55 0.03 0.47 0.17

[0068] Calculate according to the above formulas (I), (II), (III) and the ingredients in Table 2. The calculation process is shown in formulas (2-1), (2-2), (2-3):

[0069]

[0070] The depth of molten steel is 2.9m, P 压损 Generally 0.4MPa, then:

[0071] P 总 =1.2(ρ 钢 gh+P 压损 )=0.74MPa (2-2)

[0072] P Ar =P 总 -P N2 =0.7164MPa (2-3)

[0073] Adjust the pressure of nitrogen and argon to the above calculated values as required, and set the flow rate to 200Nl / min for bottom blowing nitrogen alloying; the quality of nitr...

Embodiment 3

[0074] Embodiment 3: The method of blowing nitrogen at the bottom of the ladle to increase nitrogen adopts the following specific process.

[0075] The composition of nitrogen-containing steel is shown in Table 3, and the balance is Fe and unavoidable impurities.

[0076] Table 3: Composition (wt%) of nitrogen-containing steel

[0077] element C Si mn S Cr Al Ni Mo content 0.17 0.25 0.58 0.015 1.65 0.030 1.50 0.28

[0078] Calculate according to the above formulas (I), (II), (III) and the ingredients in Table 3. The calculation process is shown in formulas (3-1), (3-2), (3-3):

[0079]

[0080] The depth of molten steel is 2.8m, P 压损 Generally 0.4MPa, then:

[0081] P 总 =1.2(ρ 钢 gh+P 压损 )=0.73MPa (3-2)

[0082] P Ar =P 总 -P N2 =0.6917MPa (3-3)

[0083] Adjust the nitrogen and argon pressures to the above calculated values as required, and set the flow rate to 200Nl / min for bottom-blowing nitrogen alloying; the quality of ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com