Self-heat-insulating building block brick of tenon-mortise heat cutoff bridge

A self-insulating block and tenon-and-mortise technology, applied in climate change adaptation, building materials, etc., can solve problems such as poor weather resistance, and achieve the effects of improving thermal comfort, convenient construction, and easy masonry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

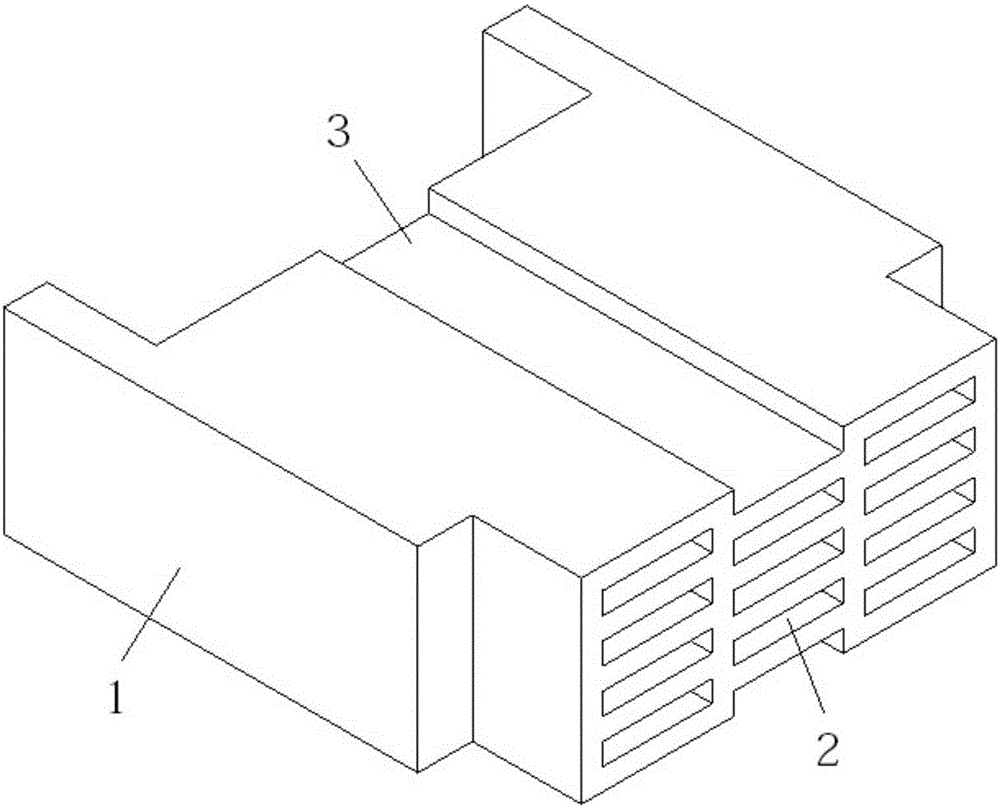

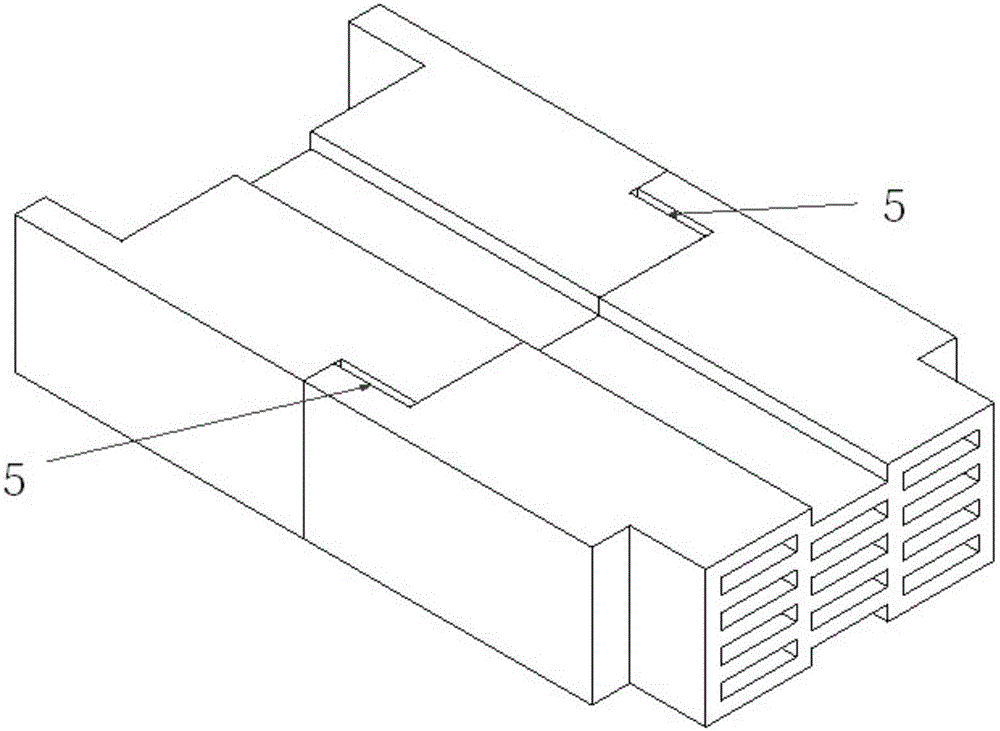

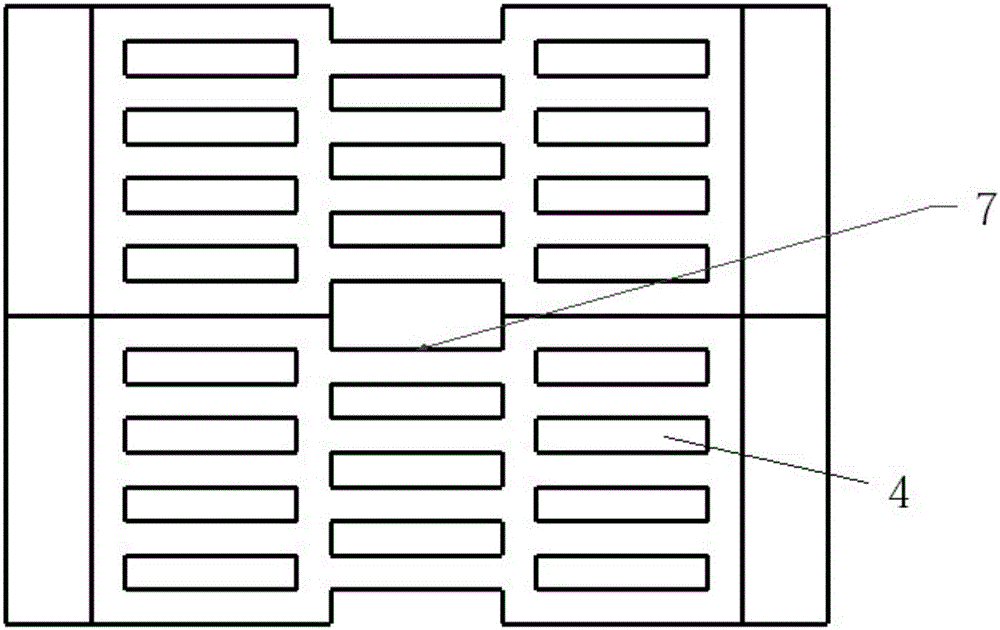

[0028] A mortise and tenon type thermal break bridge self-insulation block brick, including self-insulation masonry 1, such as Figure 1-8 As shown, several rows of transverse through holes 2 are arranged along the thickness direction of the self-insulating masonry 1, and the self-insulating masonry 1 is respectively provided with slots on the upper side and the lower side of the middle row of through holes 2 3. One end of the self-insulating masonry 1 is sunken inward and the other end is convex outward, such as figure 1 As shown, the block brick is concave on the left and convex on the right, and has three rows of transverse through holes along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com