Vertical low-temperature storage tank having slide lantern ring support mechanism

A support mechanism and low-temperature storage tank technology, applied in the direction of fixed-capacity gas storage tanks, mechanical equipment, container discharge methods, etc., can solve the problems of increased manufacturing time and difficulty, expensive radial support tubes, unstable product quality, etc. Problems, to achieve the effect of less difficulty in manufacturing and installation, simple and quick production, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

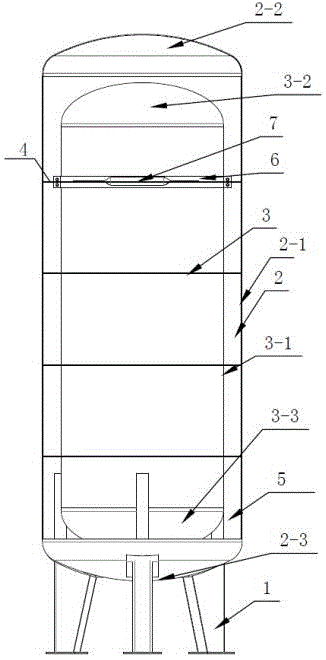

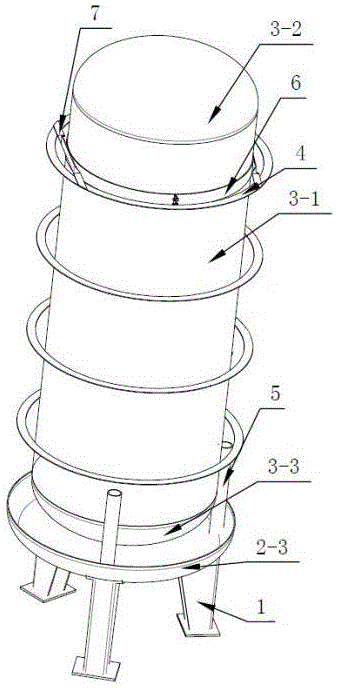

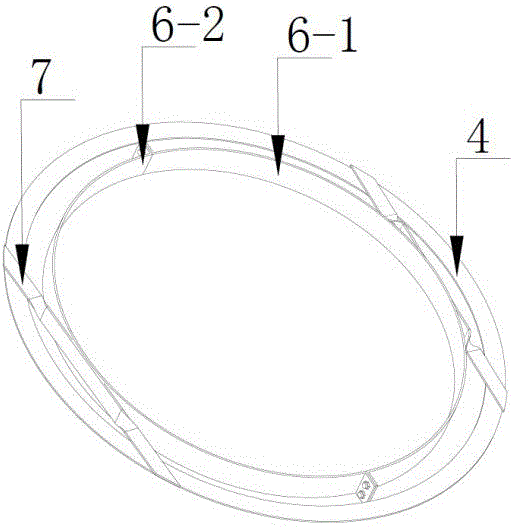

[0023] Such as Figures 1 to 4 As shown, the vertical cryogenic storage tank with a sliding collar support mechanism of the present invention includes a tank body and a leg 1, and the leg 1 is arranged at the lower part of the tank body. The tank body includes an outer container 2, an inner container 3, a reinforcing ring 4, a support tube 5 and a sliding collar support mechanism, the inner container 3 is arranged inside the outer container 2, and a closed interlayer space is formed between the outer container 2 and the inner container 3 , the reinforcing ring 4 and the sliding collar supporting mechanism are all set in the interlayer space.

[0024] The outrigger 1 is used to support and fix the tank body. By setting the tank body into a structural form including an outer container 2, an inner container 3, a reinforcement ring 4 and a supporting mechanism, the inner container 3 is used to store the solution, and the outer container 2 Used for thermal insulation protection of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com