Raw material conveying and sampling device for single crystal furnace

A raw material transportation and sampling device technology, applied in the field of floor processing, can solve the problems of high requirements and lower quality of monocrystalline silicon crystal rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

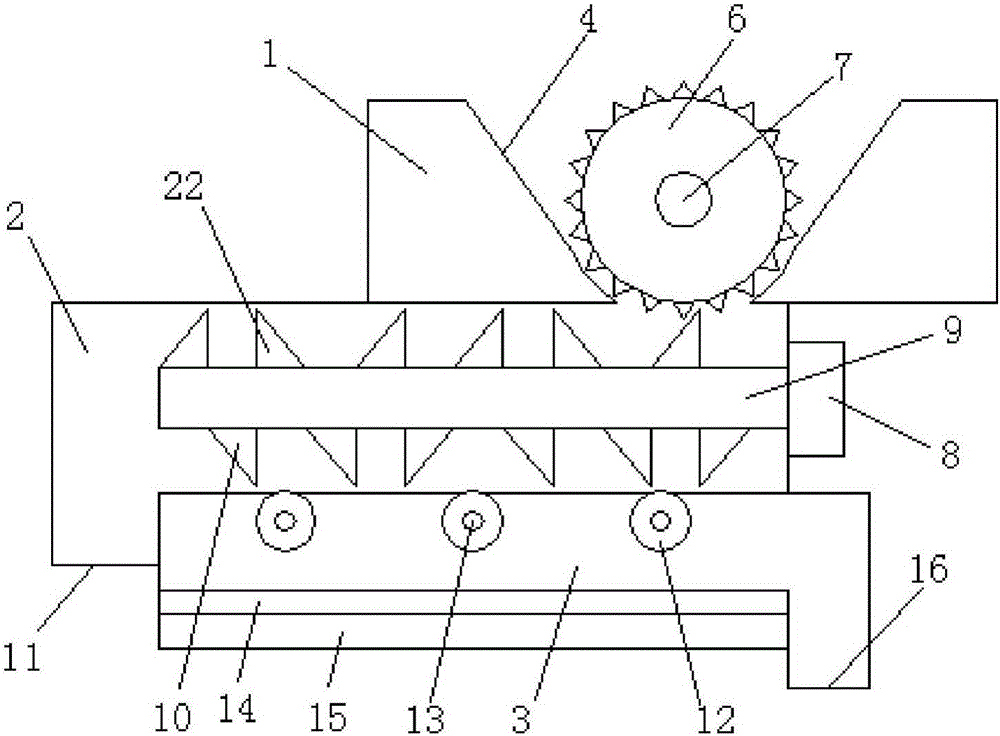

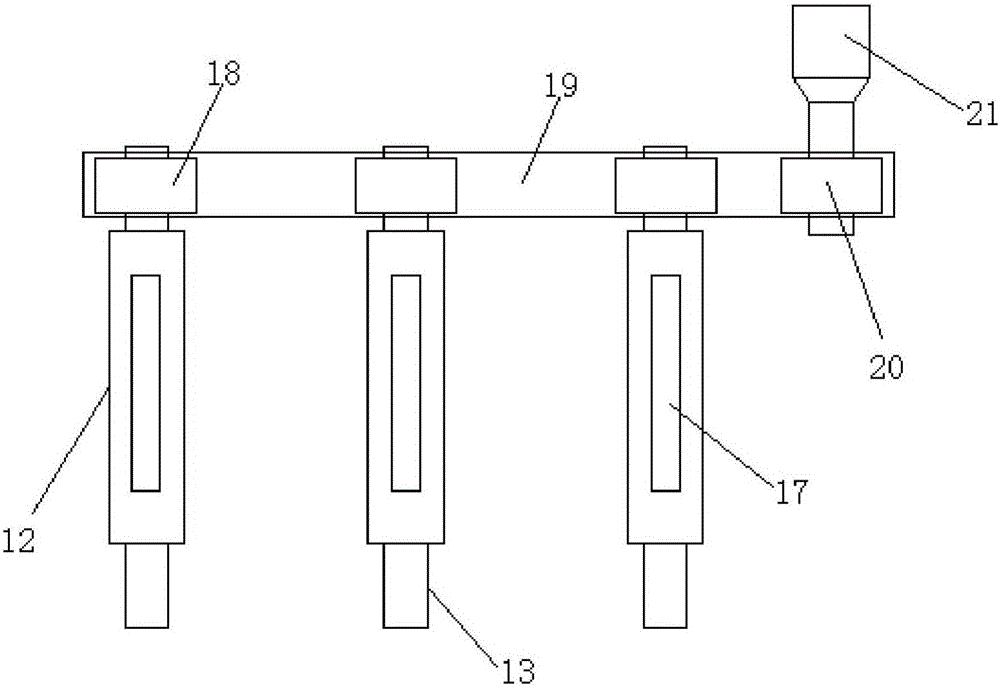

[0015] like figure 1 A raw material conveying and sampling device for a single crystal furnace is shown, which is divided into upper, middle and lower layers, wherein the upper layer is a crushing layer, the middle layer is a conveying layer, and the lower layer is a sampling layer. The bottom of the crushing layer is provided with The first discharge port, the pulverized layer communicates with the conveying layer through the first discharge port, the bottom of the conveying layer is provided with a sampling port, and the conveying layer communicates with the sampling layer through the sampling port, the The sampling layer comprises a sampling box 3, a vibrating track 14, a vibrator 15, a cylinder 12, a first rotating shaft 13 and a first motor 21, and the vibrating track 14 is arranged at the bottom of the sampling box 3, and the The vibrator 15 is connected to the bottom of the vibrating track 14, the cylinder 12 is flexibly connected to the sampling port, the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com