Anti-vibration ultraviolet germicidal lamp

A UV and anti-vibration technology, applied to the fixing/supporting parts of the luminous body, luminous body, etc., can solve the problems of poor anti-vibration performance, easy flickering of germicidal lamp ignition, etc., and achieve the effect of preventing flickering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

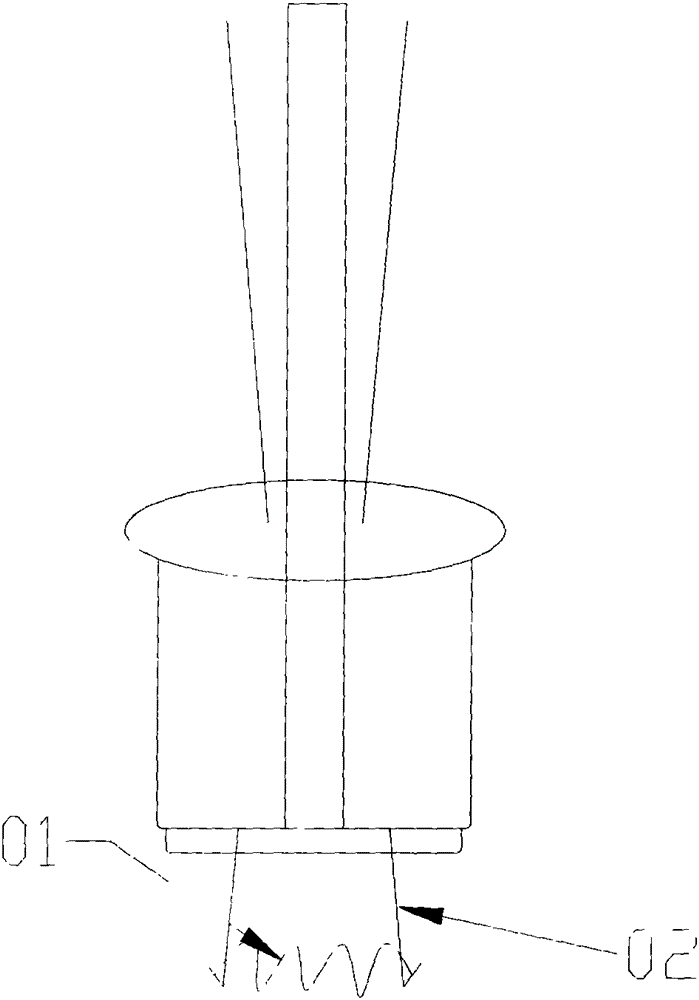

[0017] Such as figure 1 As shown, it is a traditional energy-saving wick structure, and a Dutch brand uses the wick of this structure to make ultraviolet germicidal lamps. The filament 01 is hooked on the top of the Dumet filament 02, and then both sides are stamped to fix the filament on the core to make an ultraviolet germicidal lamp. Due to the stamping structure and the material of the connecting rod that fixes the filament, the tungsten wire and the hooks on both sides will have poor contact in a vibrating environment, and it is easy to "ignite", causing the lamp to flicker randomly after ignition, or the filament to fall off. Experiments and actual use have proved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com