Milking cup set frequency conversion washing device and method

A technology of cleaning device and frequency converter, which is applied in the field of animal husbandry, can solve problems such as inability to achieve cleaning effect and increase scouring force, and achieve the effect of ensuring stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structure and working principle of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments:

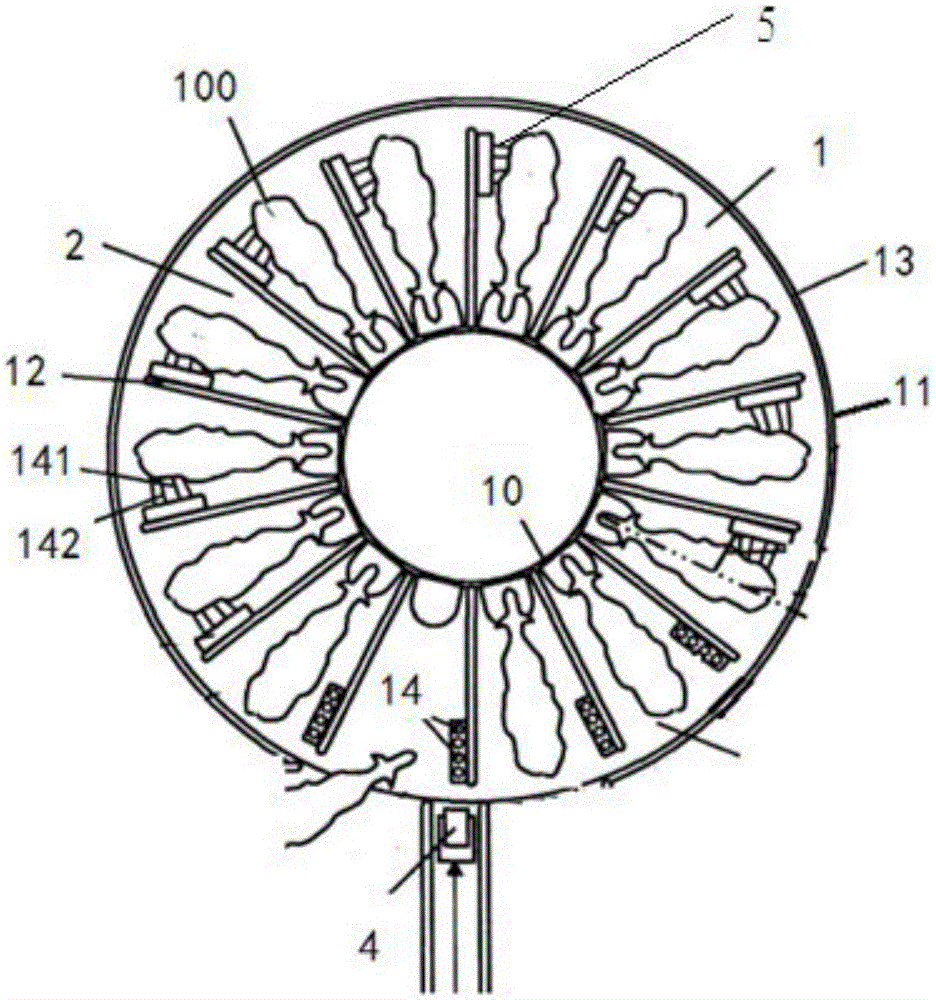

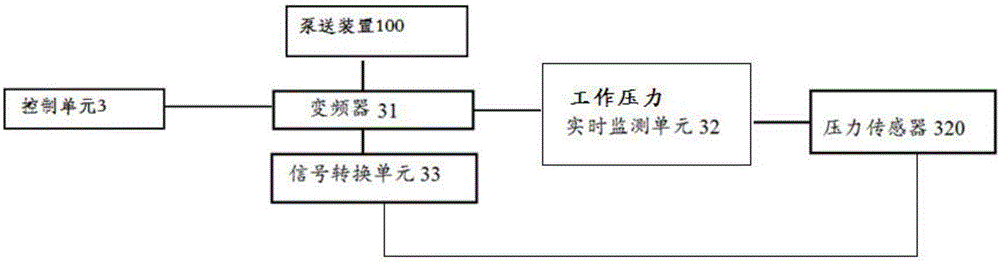

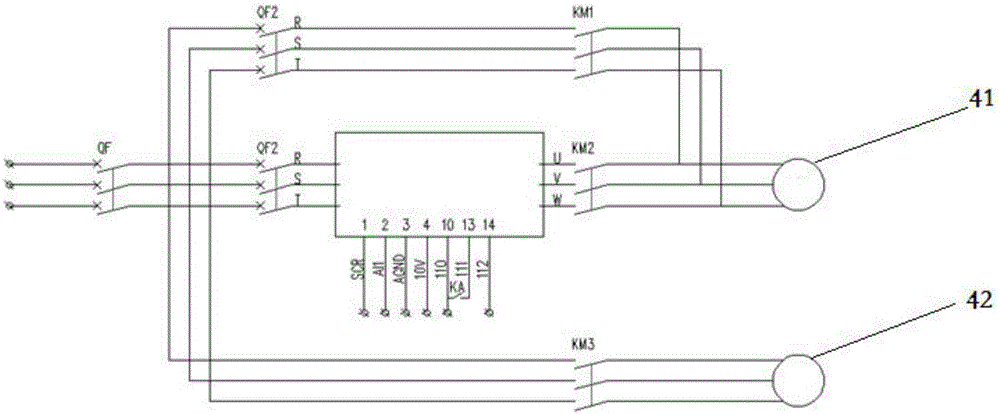

[0032] The invention provides a milking cup group frequency conversion cleaning device, such as figure 2 As shown, it includes a pipeline and a pumping device 100 , and also includes a frequency converter 31 electrically connected to the pumping device 100 , and the frequency converter 31 is preset with a first pressure signal value and a second pressure signal value.

[0033] When the milking cluster is in a milking state, the frequency converter 31 outputs a voltage according to the first pressure signal value, and when the milking cluster is in a cleaning state, the frequency converter 31 outputs a voltage according to a second pressure signal value.

[0034] Preferably, it further includes a control unit 3 electrically connected to the pumping device 100 and the frequency converter 31 , the output ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com