A kind of manufacturing process of Gannatto leisure food

A technology of snack food and production process, applied in the confectionery industry, confectionery, food science and other directions, can solve the problems of affecting the taste of the product, loss of water and dryness, and hard texture, etc. Sweet but not greasy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

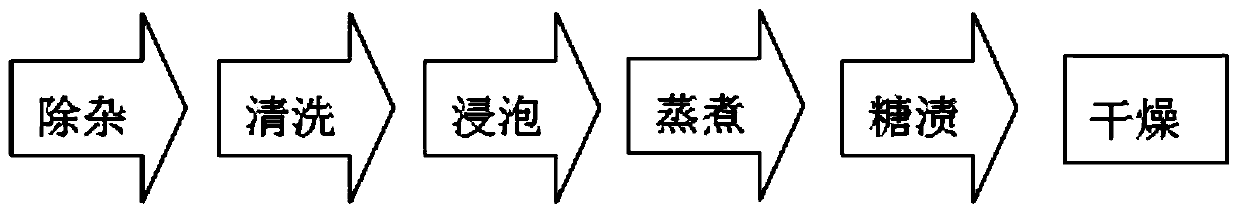

Method used

Image

Examples

example 1

[0046] 1. Weigh 4 parts of black soybeans, 100g each, wash with tap water, soak and cook in the following ways respectively, and carry out the following sugaring and drying steps under the same conditions:

[0047] A: Soak in water at 80°C for 1 hour → discard the soaking liquid, add the beans to a 3‰ sodium bicarbonate solution whose temperature has risen above 90°C, and cook for 3 hours on low heat;

[0048] B: Soak in 3‰ sodium bicarbonate solution at 80°C for 1 hour → Discard the soaking liquid, add the beans to the water whose temperature has risen above 90°C, and boil for 3 hours on low heat;

[0049] C: Soak in water at 80°C for 1 hour → discard the soaking liquid, add the beans to the water whose temperature has risen above 90°C, and cook on low heat for 3 hours;

[0050] D: Without soaking, the beans are washed and directly added to the water whose temperature has risen above 90°C, and boiled on low heat for 3 hours.

[0051] 2. Take out the beans and dip them in sug...

example 2

[0056] 1. Weigh 2 parts of black soybeans, 100g each, wash with tap water and soak in water at 80°C for 1 hour.

[0057] 2. Discard the soaking liquid, add the beans to the water containing 3‰ sodium bicarbonate whose temperature has risen above 90°C, and boil for 3 hours on low heat.

[0058] 3. Pull out the beans and soak them in sugar solutions with a concentration of 30%, 40%, and 50% (w / w) respectively. The soaking time for each gradient is 6 hours, and the soaking temperature is 55°C.

[0059] 4. Remove the beans and drain.

[0060] 5. Soak group A beans in 80% sucrose solution for 1 hour, and then drain the sugar solution; skip this step for group B beans, and directly enter the next step of drying.

[0061] 6. Dry the two batches of beans at 50°C until the surface is dry, and continue to dry in the shade at room temperature until the moisture content reaches below 20%.

[0062] Results: The skin of the beans in group A was crispy, the inside was soft, and the taste w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com