Coal bed gas mining coal powder discharge device

A coalbed methane and pulverized coal technology, which is applied in the field of pulverized coal discharge device in coalbed methane mining, can solve the problems of pump leakage, slow operation, precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

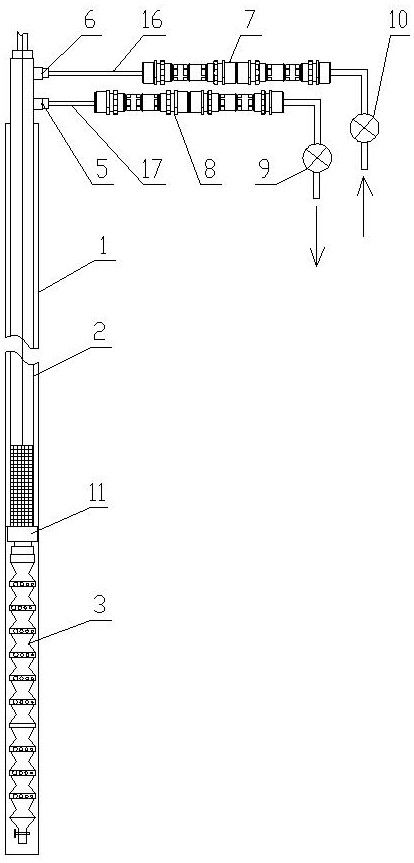

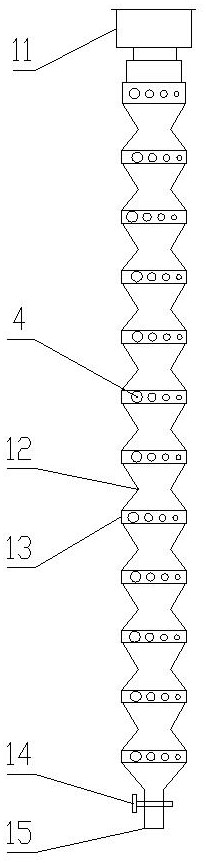

[0018] Such as figure 1 and figure 2 As shown, a pulverized coal discharge device for coalbed methane mining of the present invention includes a pulverized coal anti-settling device 3, a liquid injection assembly and a liquid discharge assembly, and the pulverized coal anti-settling device 3 is located in the shaft of a coalbed methane extraction well 1. The liquid injection assembly and the liquid discharge assembly are located outside the upper well of the coalbed methane extraction well 1. The pulverized coal anti-settling device 3 is connected to the lower end of the extraction rod 2 coaxially. The upper part is connected, the liquid injection component can inject the anti-settling agent liquid into the pulverized coal anti-settling device 3 through the extraction rod 2 in the form of pulse pressure, and the liquid drainage component can discharge the anti-settling agent 3 through the extraction rod 2 The sinking liquid is discharged.

[0019] The pulverized coal anti-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com