Processing method for Scrophulariaceae

A technology of steaming Scrophulariaceae, which is applied in the processing field of herbal medicines, can solve problems such as difficult separation and easy adhesion of Scrophulariaceae, and achieve the effect of small viscosity, large increase in active ingredient content, and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

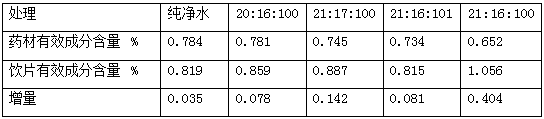

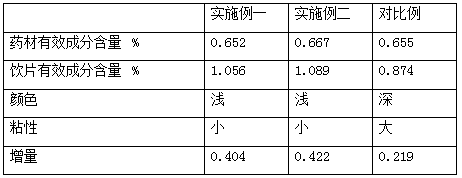

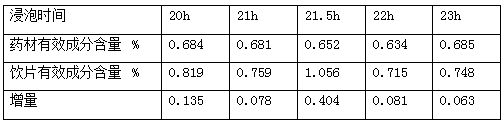

Examples

Embodiment 1

[0020] The present invention is used for the concocting method of Radix Scrophulariae, and its operating steps are as follows:

[0021] A, cutting: get 500g of Scrophulariaceae, cut Scrophulariaceae into slices under vacuum condition, the thickness of Scrophulariaceae slices is 1cm, obtain Scrophulariaceae slices;

[0022] B. Soaking: Soak Scrophulariaceae slices in 400g of pure water for 21.5h under vacuum conditions, then remove and transfer to 250g solvent oil, that is, soak in castor oil for 2h, to soak Scrophulariaceae slices, the amount of castor oil is submerged Scrophulariaceae slices;

[0023] C. Steaming: Take 42g of mint and 32g of tangerine peel, place them in 200g of water, decoct, place the infiltrated Scrophulariaceae slices in a cage drawer, and steam for 30 minutes to obtain steamed Scrophulariaceae scrophulariae slices;

[0024] D. Drying: Under vacuum conditions, dry at a temperature of 48°C for 43 minutes;

[0025] E. Testing, bagging, and finished produc...

Embodiment 2

[0027] The difference with embodiment one is: the solvent oil adopts rapeseed oil, and all the other are consistent with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com