Nano zno/c composite photocatalyst and preparation method thereof

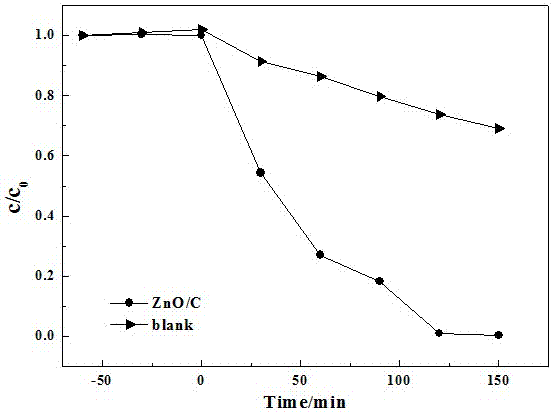

A technology of composite light and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the limited application, reduced catalytic activity of ZnO, poor visible light responsiveness, etc. To achieve the effect of enhancing adsorption, improving specific surface area and crystallinity, and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

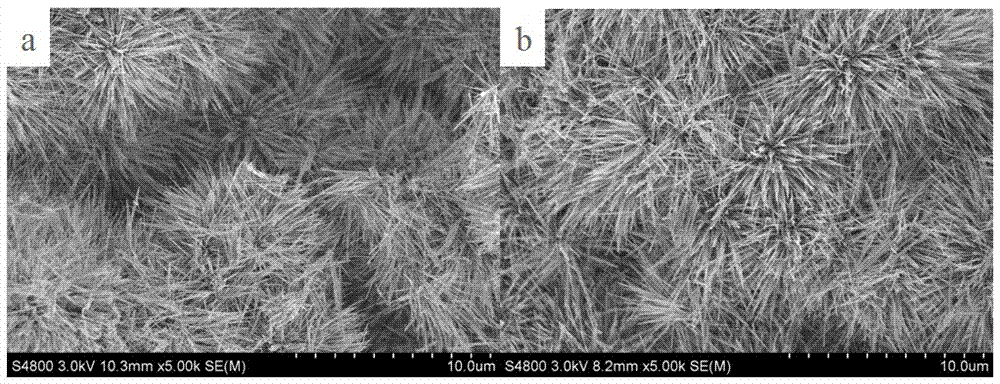

[0037] Step 1: Preparation of fireworks-like nano-ZnO:

[0038] Put zinc acetate dihydrate in a ceramic crucible, the ratio of the volume of zinc acetate dihydrate to the total volume of the crucible is 2:60, cover the crucible lid, and then place it in the cavity of a box-type resistance furnace, and heat it from room temperature to 300°C Afterwards, calcining for 3 hours, gradually lowering to room temperature, that is, generating fireworks-like nano-ZnO on the crucible wall;

[0039] Step 2: surface amination of nano-ZnO:

[0040] Weigh 0.1g of fireworks-like nano-ZnO in step 1, add it to 35mL of absolute ethanol, add dropwise 2.5g of silane coupling agent, ultrasonically disperse, then transfer to a 100mL three-neck flask, reflux at 80°C for 8h, centrifuge, and use Repeated washing with ethanol to obtain aminated nano-ZnO;

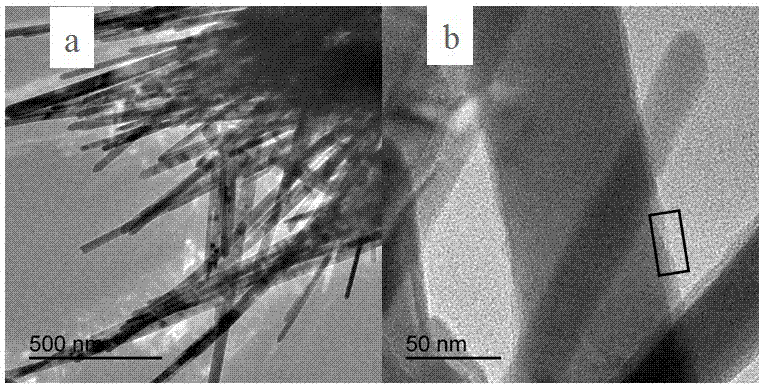

[0041] Step 3: Preparation of ZnO / C composite photocatalyst:

[0042] Weigh 0.05 g of aminated nano-ZnO and 0.05 g of glucose, dissolve them in eth...

Embodiment 2

[0045] Step 1: Preparation of fireworks-like nano-ZnO:

[0046] Put zinc acetate dihydrate in a ceramic crucible, the ratio of the volume of zinc acetate dihydrate to the total volume of the crucible is 2.5:60, cover the crucible lid, and then place it in the cavity of a box-type resistance furnace, and heat it from room temperature to 300°C Afterwards, calcining for 2 hours, gradually lowering to room temperature, that is, generating fireworks-like nano-ZnO on the crucible wall;

[0047] Step 2: surface amination of nano-ZnO:

[0048]Weigh 0.2g of fireworks-like nano-ZnO in step 1, add it to 30mL of absolute ethanol, add dropwise 2.7g of silane coupling agent, ultrasonically disperse, then transfer to a 100mL three-neck flask, reflux at 80°C for 7.5h, and centrifuge. And repeatedly washed with ethanol to obtain aminated nano-ZnO;

[0049] Step 3: Preparation of ZnO / C composite photocatalyst:

[0050] Weigh 0.05 g of aminated nano-ZnO and 0.1 g of glucose, dissolve them in ...

Embodiment 3

[0053] Step 1: Preparation of fireworks-like nano-ZnO:

[0054] Put zinc acetate dihydrate in a ceramic crucible, the ratio of the volume of zinc acetate dihydrate to the total volume of the crucible is 3:60, cover the crucible lid, and then place it in the cavity of a box-type resistance furnace, and heat it from room temperature to 300 °C Afterwards, calcining for 1 h, gradually lowering to room temperature, that is, generating fireworks-like nano-ZnO on the crucible wall;

[0055] Step 2: surface amination of nano-ZnO:

[0056] Weigh 0.3g of fireworks-like nano-ZnO in step 1, add it to 25mL of absolute ethanol, add 3g of silane coupling agent dropwise, ultrasonically disperse, then transfer to a 100mL three-necked flask, condense and reflux at 80°C for 7h, centrifuge, and wash with ethanol Repeated washing to obtain aminated nano-ZnO;

[0057] Step 3: Preparation of ZnO / C composite photocatalyst:

[0058] Weigh 0.05 g of aminated nano-ZnO and 0.2 g of glucose, dissolve t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com