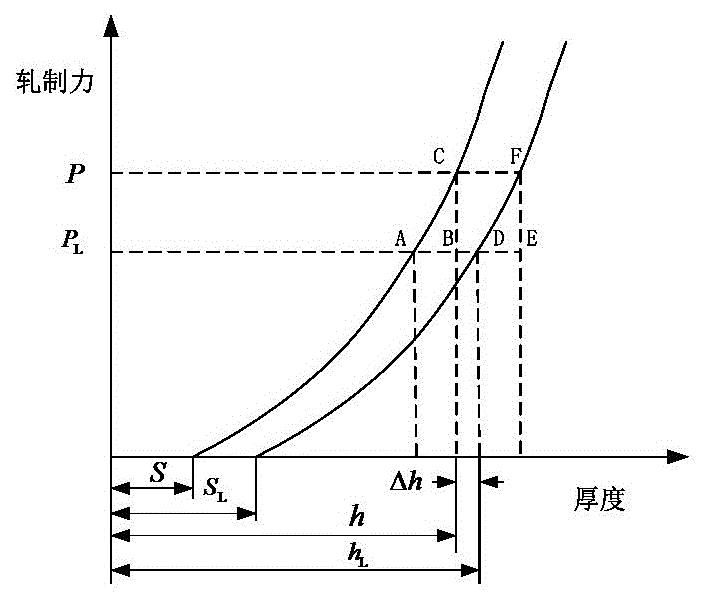

Plate strip rolling thickness control method based on mill spring characteristic curve

A technology of characteristic curve and rolling mill bounce, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as thickness control error adjustment, wrong adjustment, inaccurate thickness control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

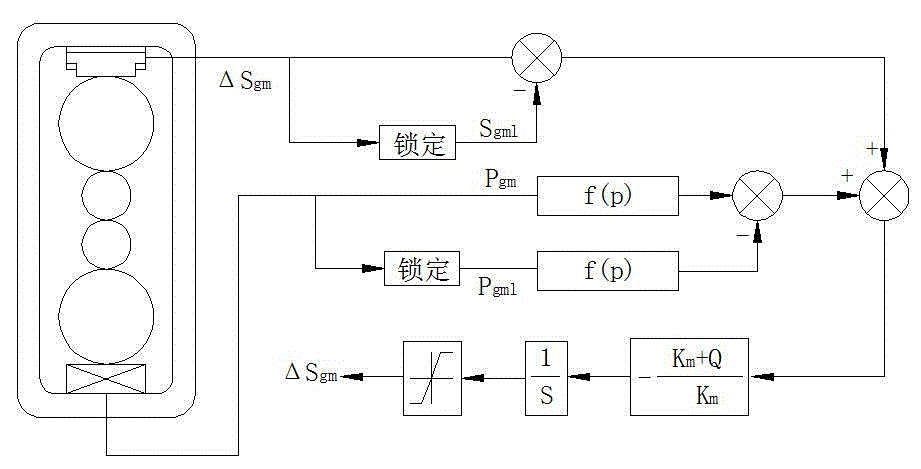

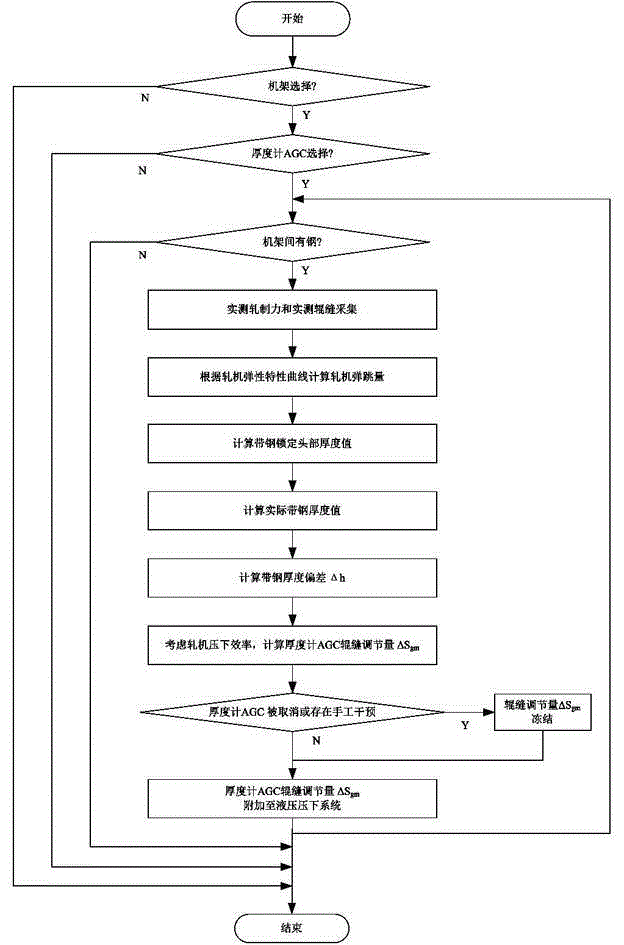

Method used

Image

Examples

Embodiment 1

[0061] Select rolling steel grade: Q345

[0062] Incoming material width 1250mm, incoming material thickness 10.95mm, outlet thickness 8.45mm, rolling speed 7.5m / s

[0063] Rolling mill stiffness M = 6500kN / mm, strip plastic coefficient Q = 8250kN / mm,

[0064] alpha 1 = 0.16049, α 2 = 0.00569, α 3 = 0.01343, α 4 =-0.00156,

[0065] beta 0 =-0.0012, β 1 = 0.0000015, β 2 = -1.034846923, β 3 =0.042211566

[0066] P st =600kN, P s =200kN, η=0.0001, ε=1000mm.

[0067] The thickness gauge AGC control parameters and methods based on the above conditions are as follows:

[0068] (1), the relevant data of rolling mill and strip steel are input into computer, the rigidity factor M=6500kN / mm of rolling mill, the strip steel plastic coefficient Q=8250kN / mm; Determine the thickness control object proportional coefficient:

[0069] K = 1 + Q K m = 1 ...

Embodiment 2

[0080] Select rolling steel grade: Q235

[0081] Incoming material width 520mm, incoming material thickness 4.71mm, outlet thickness 3.95mm, rolling speed 9.0m / s

[0082] Rolling mill stiffness M = 3160kN / mm, strip plastic coefficient Q = 2850kN / mm,

[0083] alpha 1 = 0.25166, α 2 =-0.05828, α 3 = 0.04326, α 4 =-0.00497,

[0084] beta 0 = -0.001244, β 1 =3.56E-06,β 2 =-0.598, β 3 =0.0357

[0085] P st =600kN, P s =200kN, η=0.0001, ε=450mm.

[0086] The thickness gauge AGC control parameters and methods based on the above conditions are as follows:

[0087] (1), the relevant data of rolling mill and strip steel are input into computer, the rigidity coefficient M=3160kN / mm of rolling mill, the strip steel plastic coefficient Q=2850kN / mm; Determine the thickness control object proportional coefficient:

[0088] K = 1 + Q K m = 1 + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com