Fret saw cutting device

A technology of cutting equipment and wire saw, applied in the direction of metal sawing equipment, metal processing equipment, sawing machine, etc., can solve the problems of huge equipment, low efficiency of driving mode, and inability to meet the processing needs of mass products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

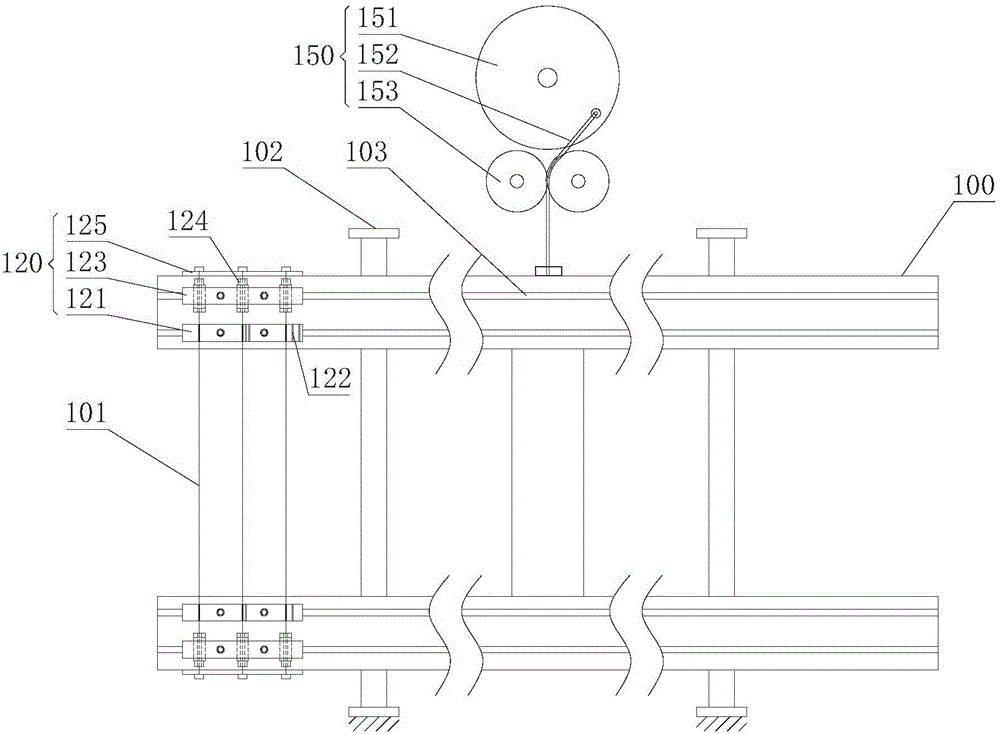

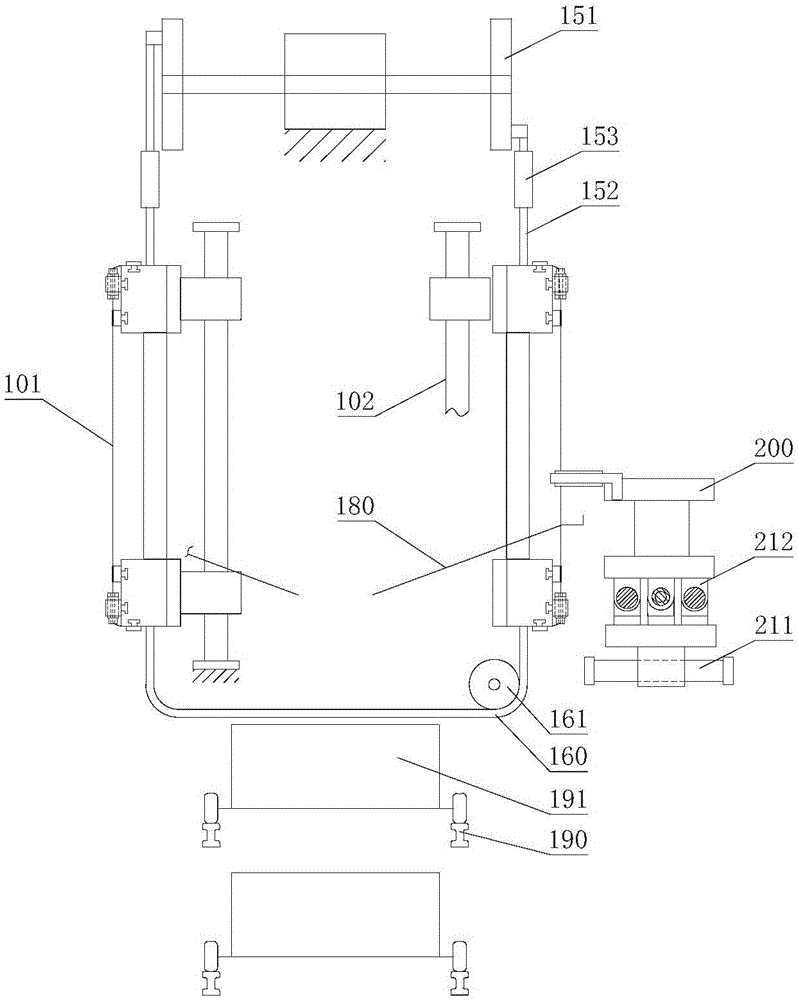

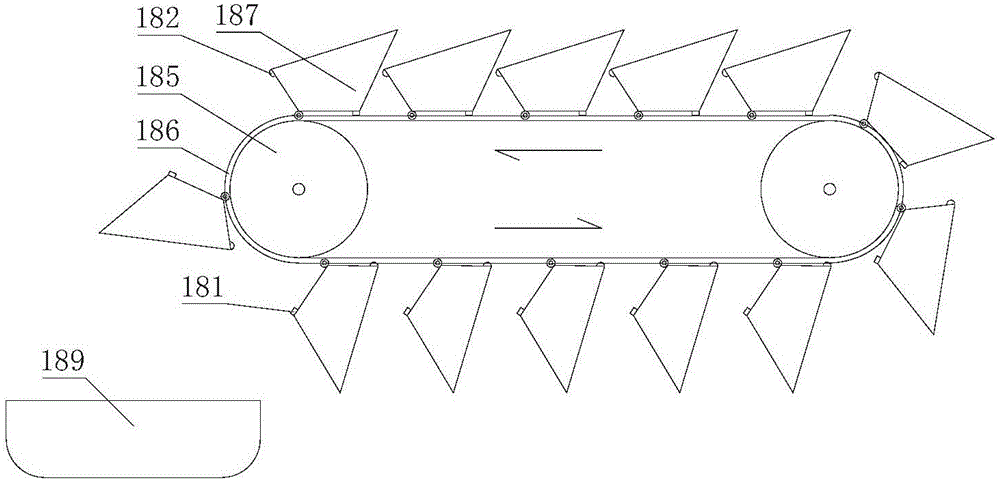

[0071] Such as Figure 1 to Figure 2 As shown, the wire saw cutting equipment described in the preferred embodiment of the present invention includes a wire saw bracket 100 and a positioning fixture 200, and a wire saw 101 is installed side by side on the wire saw bracket 100, and the wire saw bracket 100 is a wire saw Driven by the rack driving mechanism 150, the linear saw 101 is driven to perform linear reciprocating motion, preferably linear reciprocating motion in the Z direction, and the positioning fixture 200 is driven to move on a horizontal plane, preferably an X-Y horizontal plane, driven by the clamp driving mechanism. The positioning fixture 200 can carry out rotation and linear displacement movement o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com