Single-arm mechanical hand

A manipulator and single-arm technology, applied in the direction of manipulators, program-controlled manipulators, spraying devices, etc., can solve the problems of unfavorable popularization and application, high manufacturing cost, and large space occupation, so as to reduce costs, improve spraying accuracy, and high transmission force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

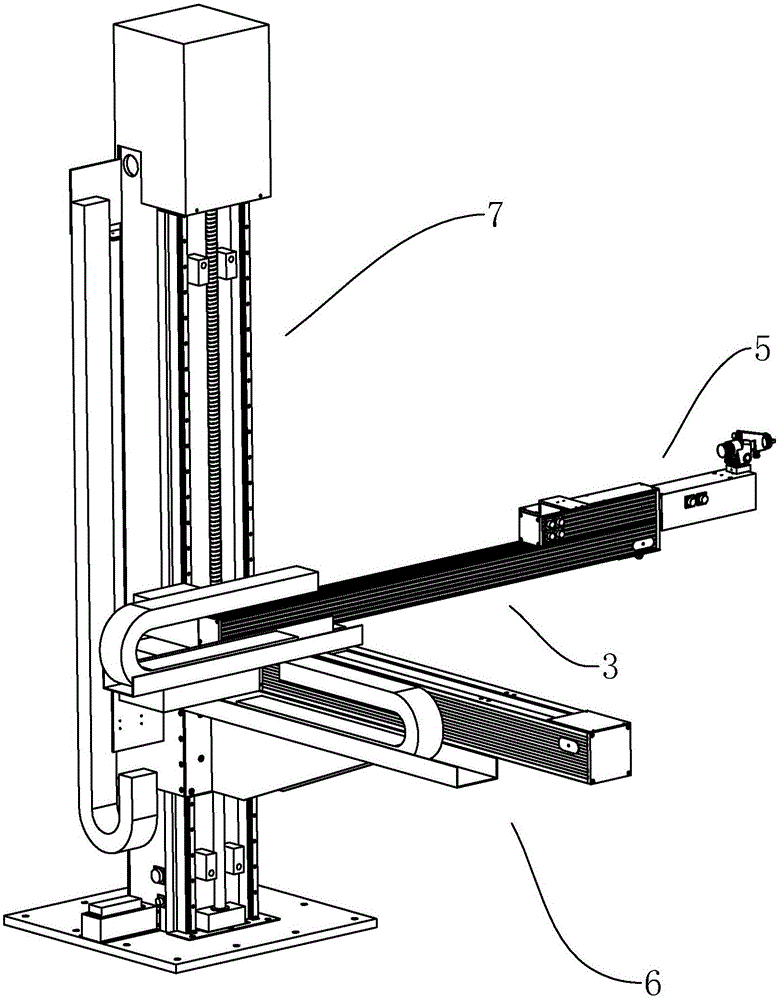

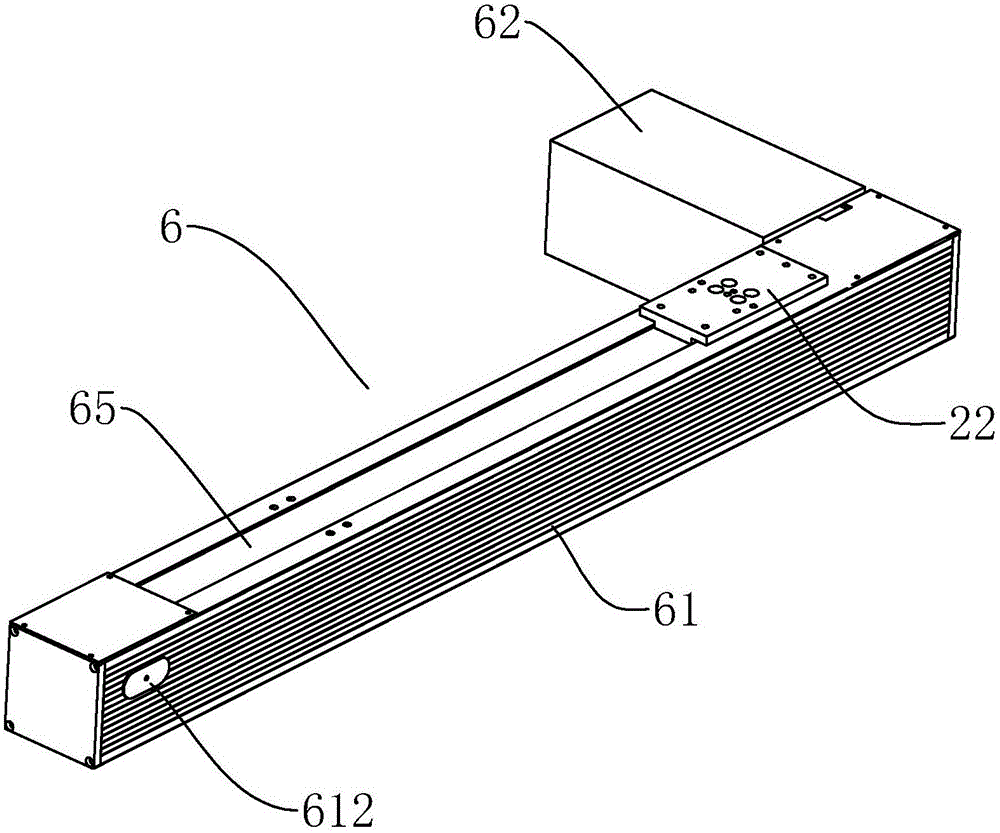

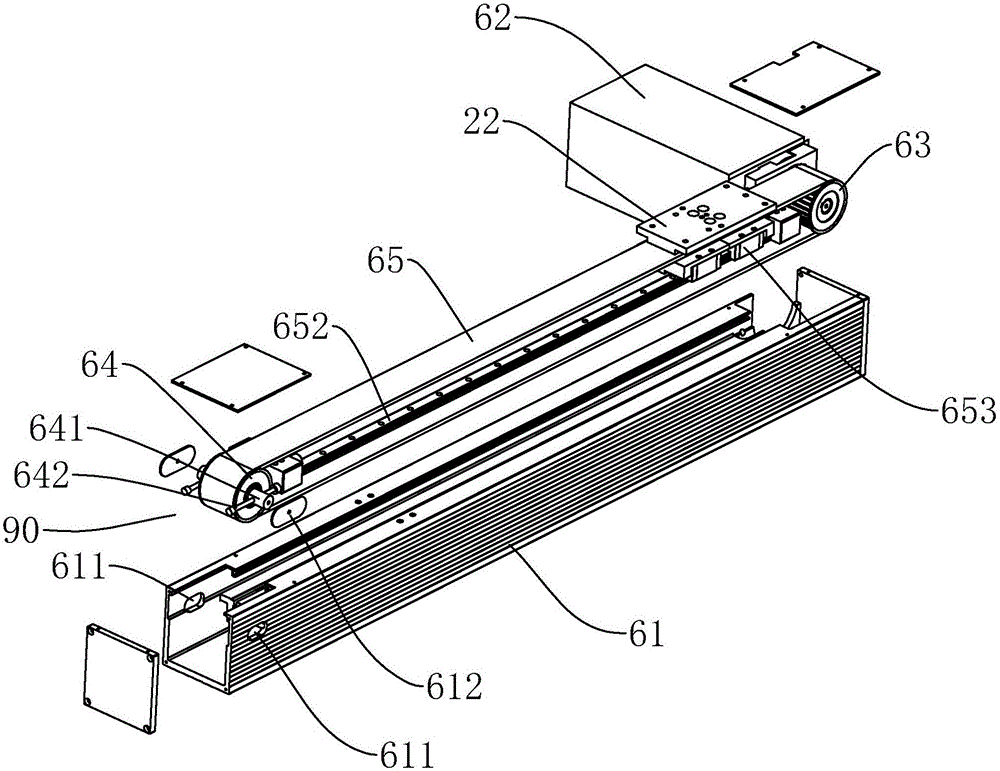

[0032] refer to Figure 1 to Figure 10 , Figure 1 to Figure 10 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a single-arm manipulator includes a column mechanism 7, a cross-arm mechanism 6, a telescopic arm mechanism 3, and a spray gun mechanism 5.

[0033] As shown in the figure, the column mechanism 7 includes a base 71, a column 72 arranged on the base 71, a column sliding table 73 slidably arranged on the column 72, and a transmission mechanism that can drive the column sliding table 73 to lift and slide. In an example, the transmission mechanism is a screw transmission mechanism, and the screw transmission mechanism includes a screw motor 74, a transmission screw 75 arranged along the length direction of the column 72, and a screw nut 76 arranged on the transmission screw 75 , the screw motor 74 is arranged on the top of the column 72, and the screw motor 74 is connected with the transmission screw 75 aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com