A direct drive wheel device based on a reluctance switch motor and its implementation method

A reluctance switching motor, reluctance technology, applied in electromechanical devices, motors, power devices and other directions, can solve the problems of obvious torque discontinuity, complex driving structure, high cost, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments.

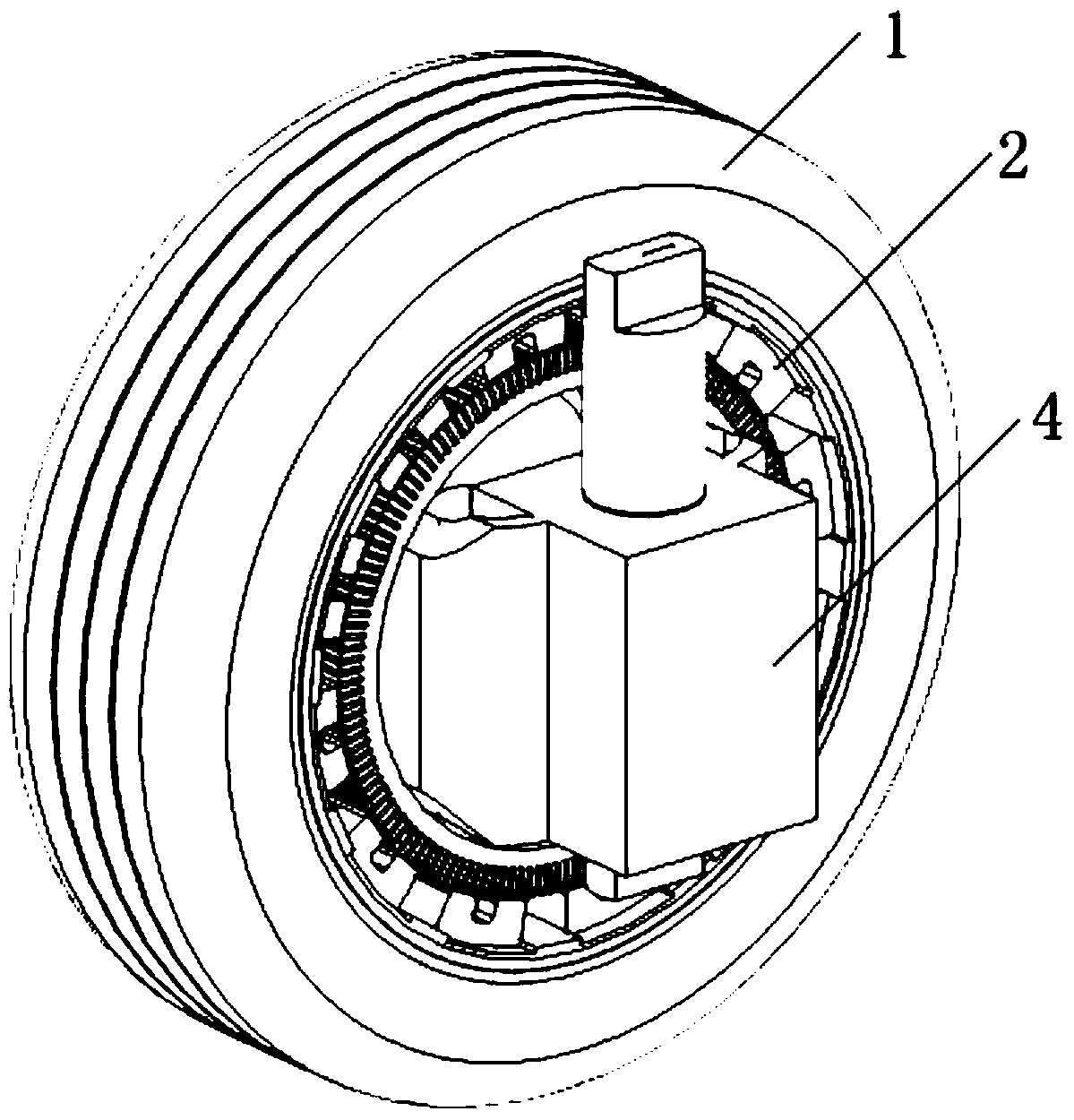

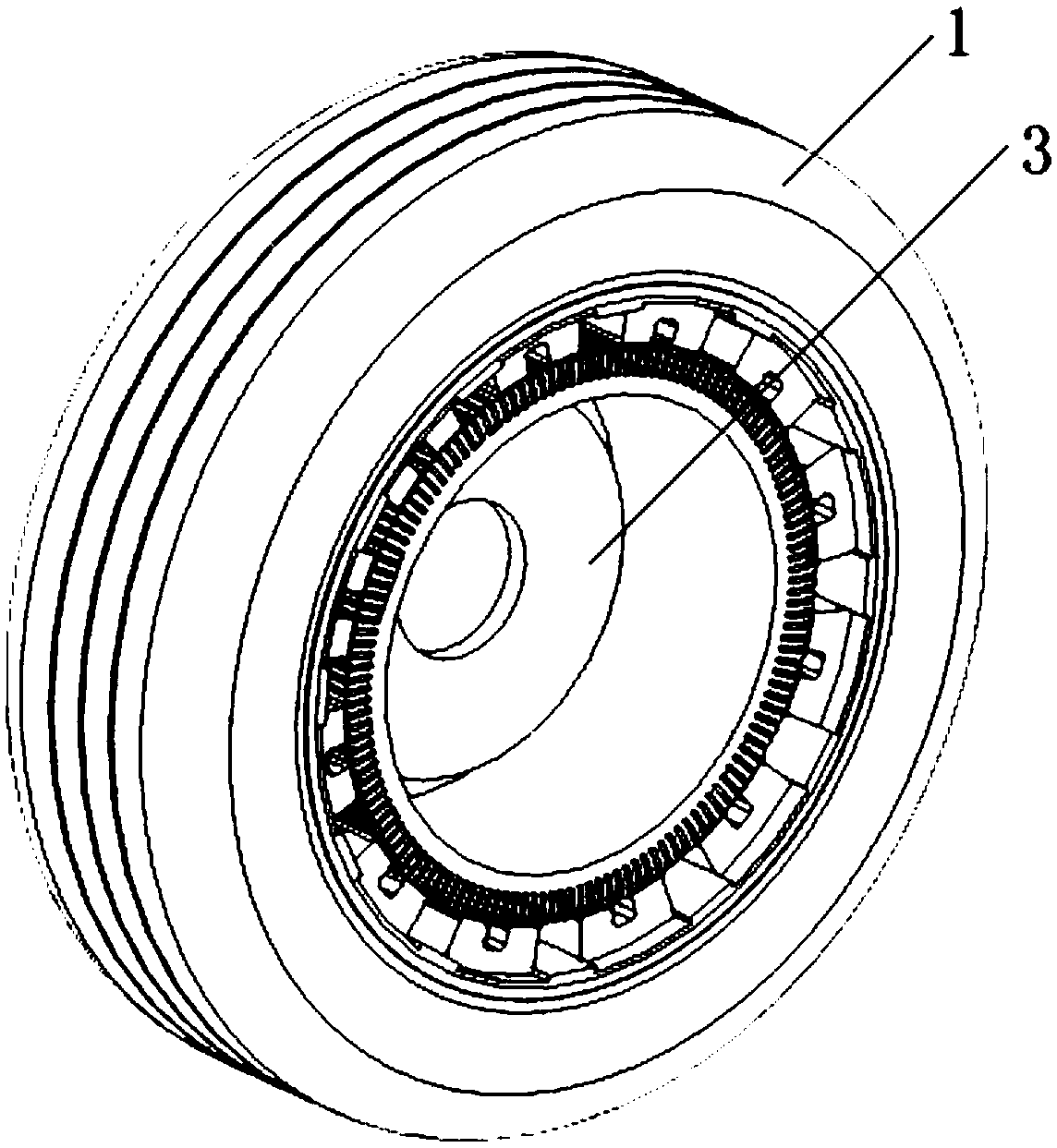

[0029] Such as Figure 1 to Figure 5 As shown, a direct drive wheel device based on a reluctance switch motor, the device includes a tire 1, and a reluctance outer rotor direct drive motor 2 arranged in the tire 1, the reluctance outer rotor direct drive motor 2 is set There are reduction gear 3 and steering gear 4.

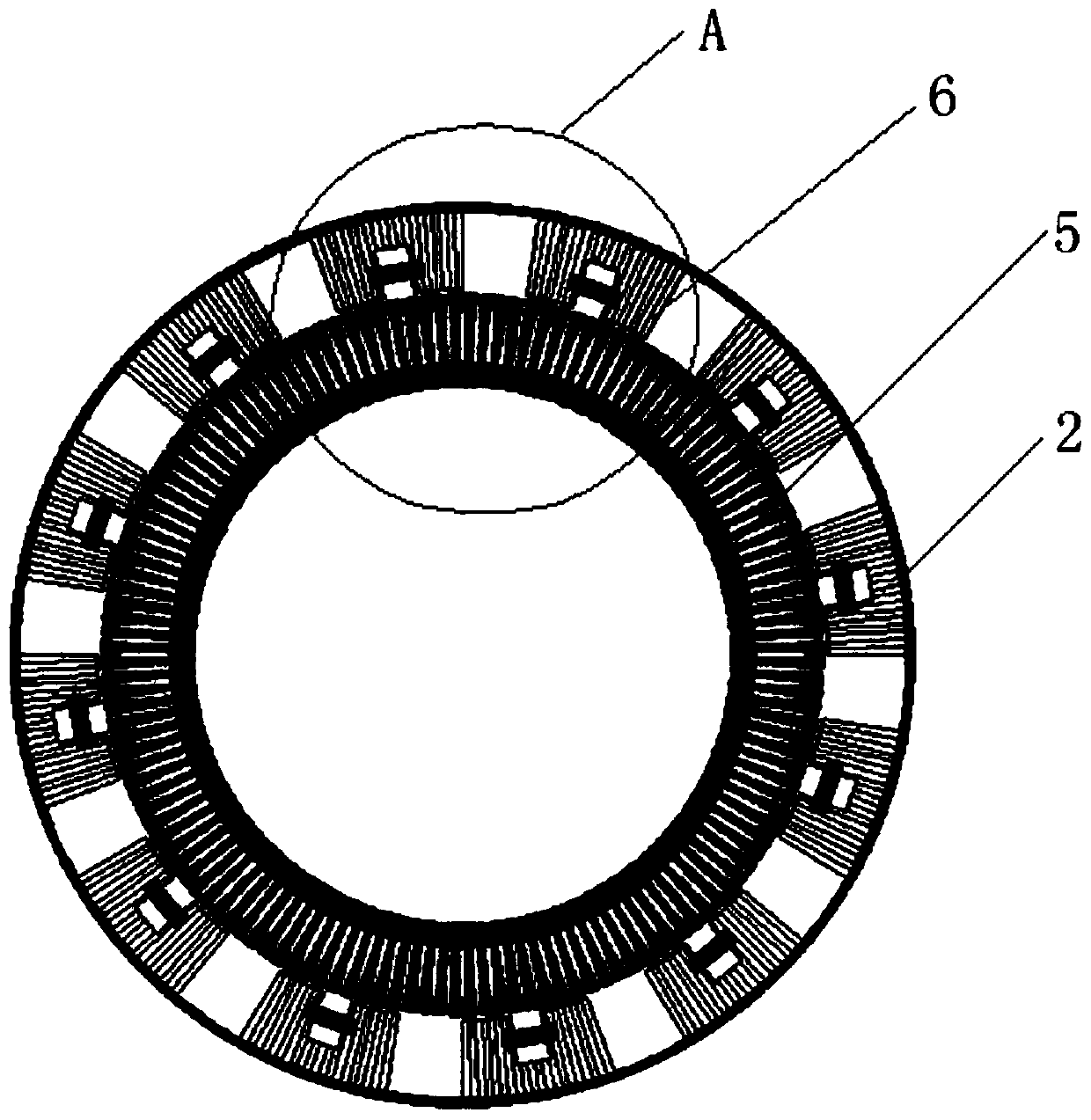

[0030] The reluctance outer rotor direct drive motor 2 is composed of an inner stator 5 and an outer rotor 6; when the reluctance outer rotor direct drive motor 2 operates, each magnetic field of the inner stator 5 dynamically adjusts poles, and continuous excitation can generate uninterrupted torque peak.

[0031] Each subdivided stator pole of the inner stator 5 has independent coils and switches, and dynamically paired series windings, multiple paired series windings form a magnetic field, simultaneously excite all rotor poles, and output multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com