Electric power-assisted trolley

An electric power assist and trolley technology, applied in the field of trolleys, can solve the problems of high cost, complicated operation, easy failure, etc., and achieve the effect of saving precious time, high moving efficiency, and avoiding low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

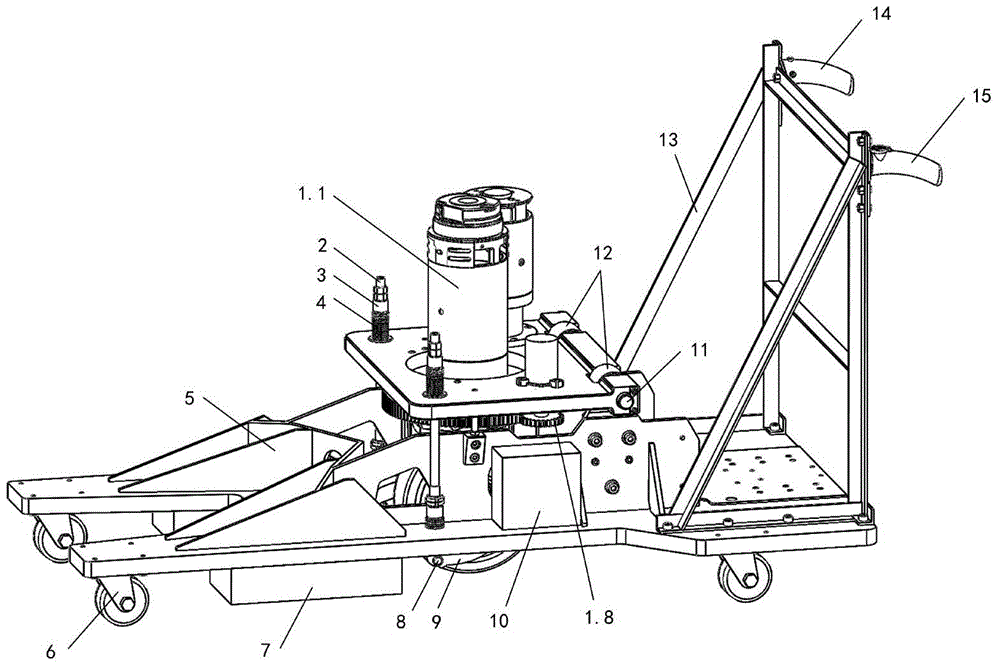

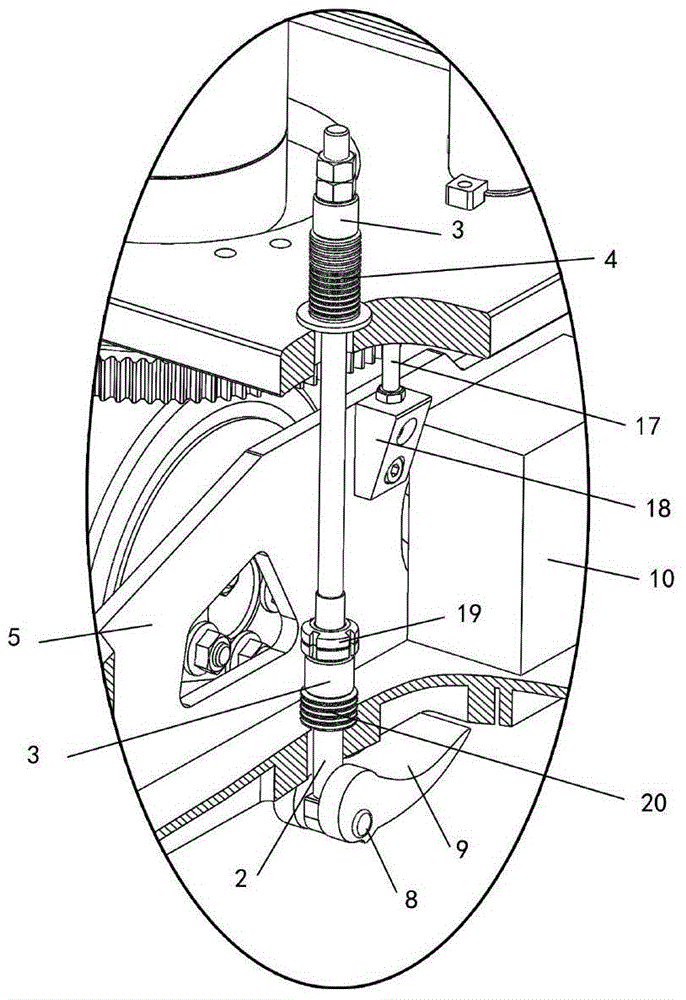

[0019] exist figure 1 In the schematic diagram of the electric power-assisted trolley shown, an oval through-hole is provided in the middle of the base 5, vertical ribs are respectively welded longitudinally on both sides of the through-hole, and universal wheels 6 are arranged at the bottom of the frame, respectively for the left front wheel , the right front wheel, the left rear wheel and the right rear wheel, the floor brake 21 is located at the middle part of the bottom rear end of the base, the battery 7 is located at the bottom of the base 5, and the control unit 10 is located at the base next to the rib plate on one side On the inside, the control unit 10 is integrated with a single-chip microcomputer, which processes the information input by the direction knob 16, the drive button and the encoder 1.2 and outputs it to the drive motor 1.1 and the steering motor 1.7;

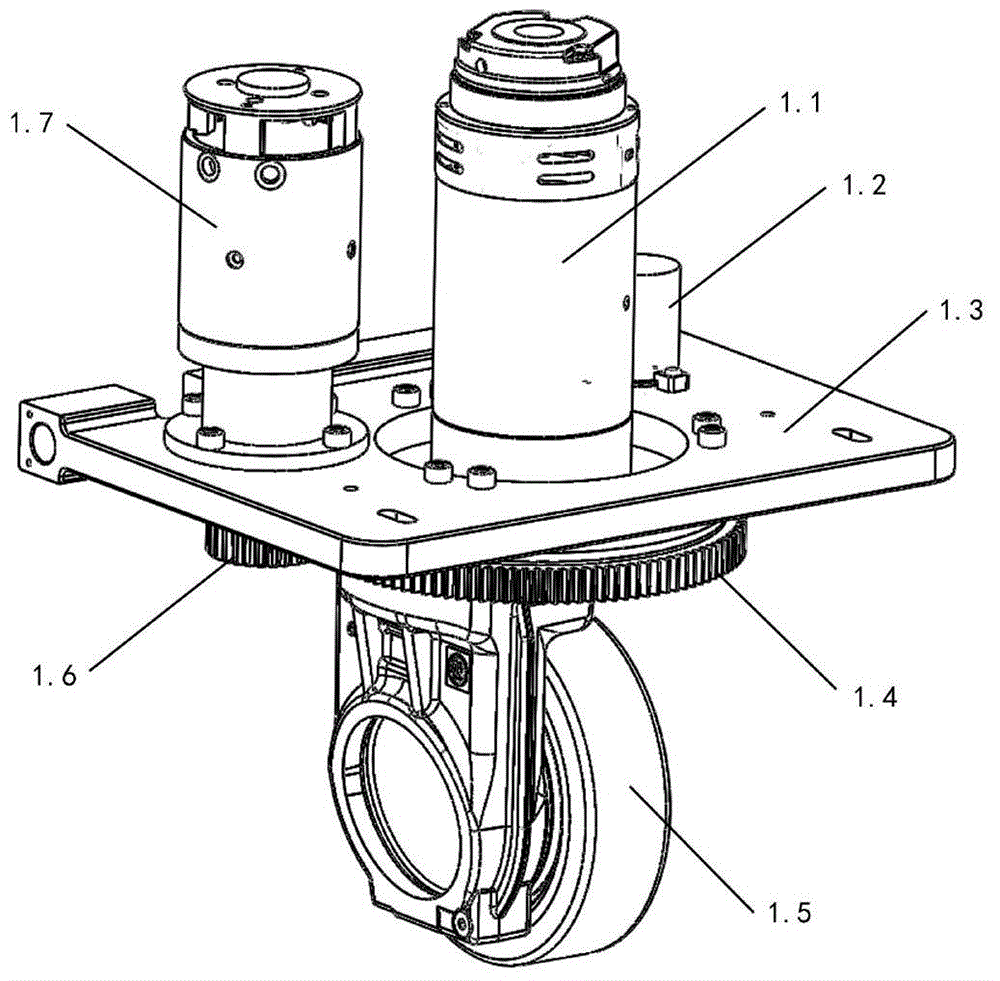

[0020] The drive unit adopts the drive unit of model MRT23.D0002 purchased from the market. The drive u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com