Fault detecting method for braking device

A technology for fault detection and braking device, which is used in hoisting devices, transportation and packaging, elevators, etc., can solve problems such as low economic benefits, low braking force, safety accidents, etc., achieve the effect of various detection modes and improve the inspection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

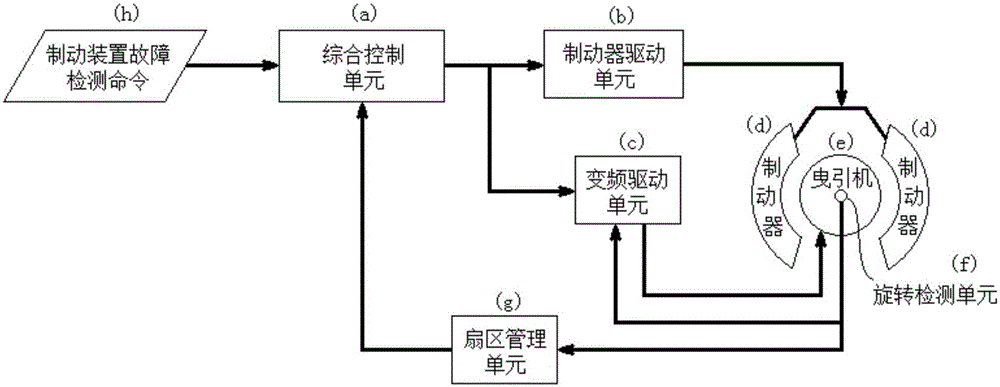

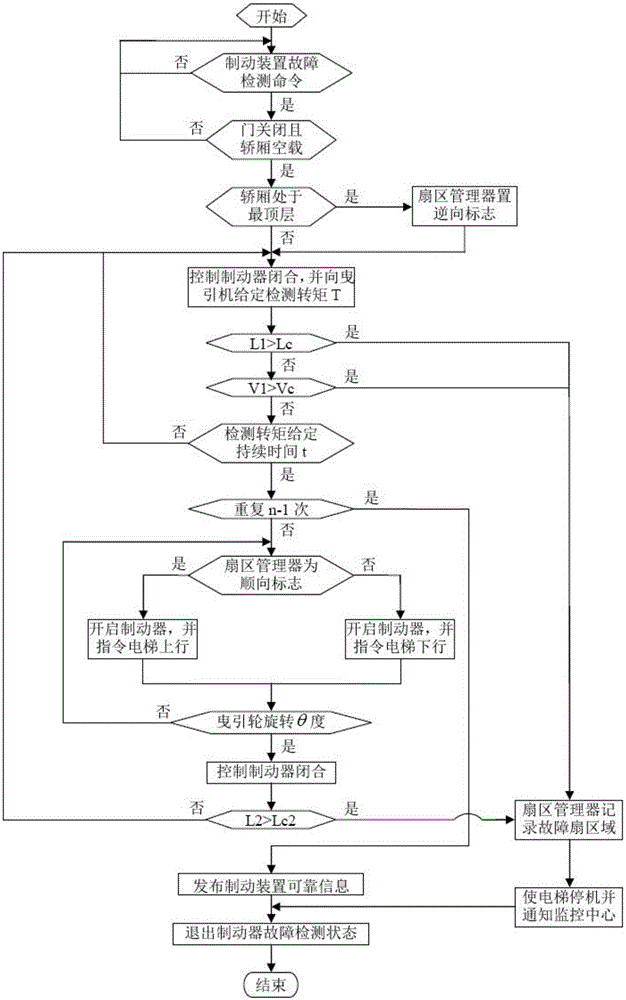

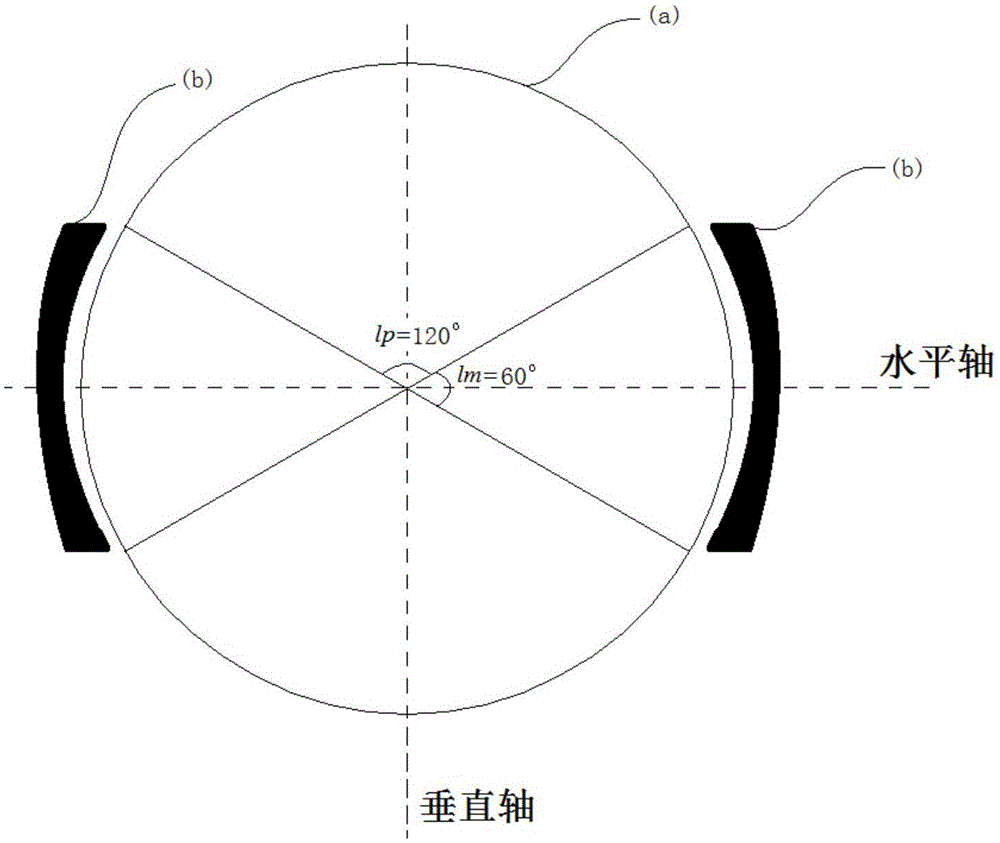

[0020] like figure 1 As shown, the brake device fault detection method of the present invention is realized by the following system: including a variable frequency drive unit, a sector management unit, a brake drive unit, a rotation detection unit, and an integrated control unit, wherein the integrated control unit can output and send the brake drive unit The command to open and close the brake can receive the sector test sequence from the sector management unit, and send the running command of the traction machine to the variable frequency drive unit, and the variable frequency drive unit can control the speed, position, Torque control, the sector management unit can diagnose and record the reliability of the cooperation between the brake shoe and each sector on the brake drum, and guide the comprehensive control unit to execute the detection sector sequence, the brake drive unit The opening and closing of the brake can be driven, and the rotation detection unit can detect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com