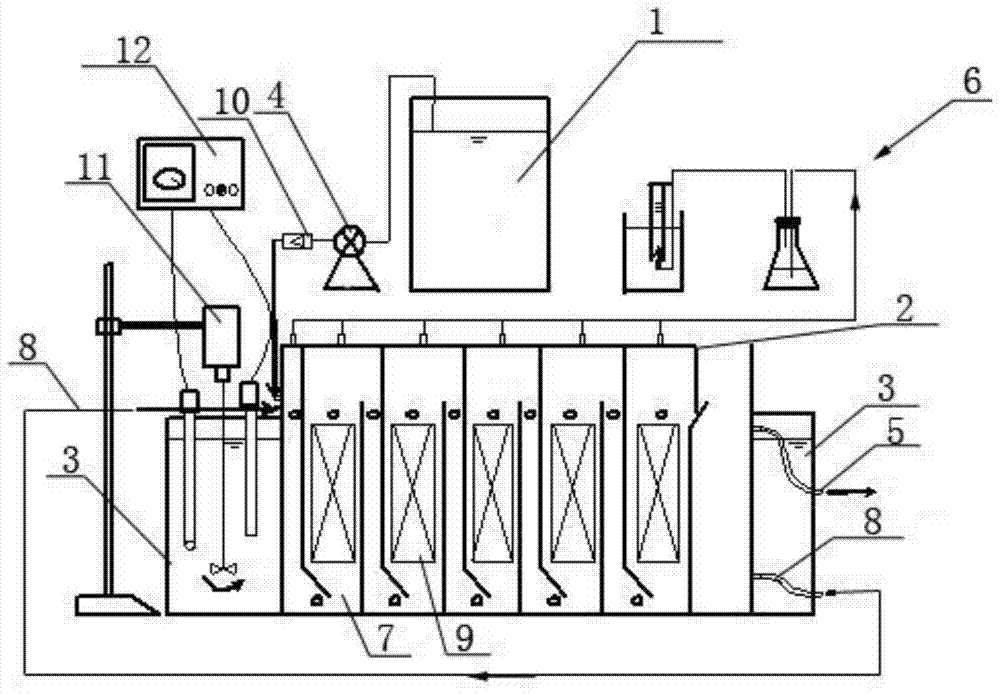

abr anaerobic baffle reactor and treatment method for high-salt and high-cod concentration wastewater

An anaerobic baffle and treatment method technology, applied in the field of industrial wastewater purification, can solve the problems of high cost, high treatment cost, difficult inhibition effect, etc., and achieve the effects of high removal rate, fast start-up, and stable water effluent effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

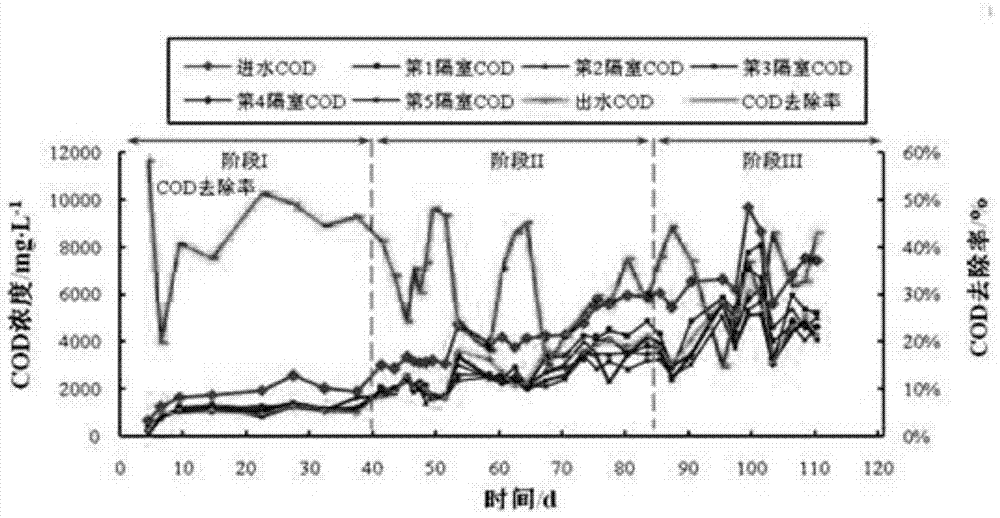

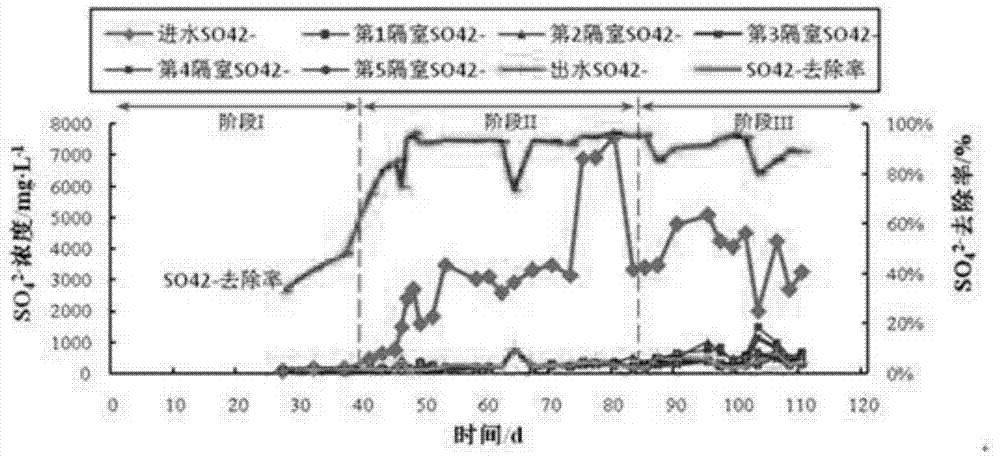

[0060] First, adjust the pH of the wastewater with a COD concentration of 580mg / L to 8. The wastewater contains a high concentration of sulfate, and its concentration is about 10671mg / L, and then it is introduced into the first compartment of the ABR anaerobic baffle reactor. In the room, under the condition of 34 °C water bath, the wastewater flows through each compartment one by one in the ABR anaerobic baffle reactor for reaction, and the hydraulic retention time is controlled to be 36h; it flows out of the last compartment of the ABR anaerobic baffle reactor 60% of the water is returned to the first compartment of the ABR anaerobic baffle reactor, and the concentration of the incoming water is diluted by continuous reflux, thereby increasing the volume load of the ABR anaerobic baffle reactor; this stage maintains 60 Days later, the removal rate of salt and COD of the treated water was detected, and the removal rate of salt and COD measured on the 61st to 65th day was stabl...

Embodiment 2

[0067] First, adjust the pH of the wastewater with a COD concentration of 2000mg / L to 8, and then introduce it into the first compartment of the ABR anaerobic baffle reactor. 55% of the water flowing out of the last compartment of the ABR anaerobic baffle reactor is returned to the first one of the ABR anaerobic baffle reactor. In the cell; after this stage is maintained for 70 days, the removal rate of salt and COD in the treated water is detected, and the removal rate of salt and COD measured on the 72nd to 77th day is stable, which are 95% and 48.1% respectively, and the start-up stage is completed .

[0068]After the start-up of the ABR anaerobic baffle reactor is completed, the pH of the wastewater with a COD concentration of 6000mg / L is adjusted to 8, and then it is introduced into the first chamber of the ABR anaerobic baffle reactor, and the water bath condition is 34°C The waste water flows through each compartment one by one in the ABR anaerobic baffle reactor for r...

Embodiment 3

[0071] Firstly, adjust the pH of wastewater with a COD concentration of 1500mg / L to 8, and then introduce it into the first chamber of the ABR anaerobic baffle reactor. 65% of the water flowing out of the last compartment of the ABR anaerobic baffle reactor is returned to the first one of the ABR anaerobic baffle reactor. In the cell; after this stage is maintained for 60 days, the removal rate of salt and COD in the treated water is detected, and the removal rate of salt and COD measured on the 65th to 71st day is stable, which are 95% and 37.1% respectively, and the start-up phase is completed .

[0072] After the start-up of the ABR anaerobic baffle reactor is completed, the pH of the wastewater with a COD concentration of 4500mg / L is adjusted to 8, and then it is introduced into the first compartment of the ABR anaerobic baffle reactor, and the water bath condition is 35°C The waste water flows through each compartment one by one in the ABR anaerobic baffle reactor for re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com