ABR anaerobic baffle plate reactor for cultivating wastewater treatment

A technology of anaerobic baffles and aquaculture wastewater, applied in the field of ABR anaerobic baffle reaction devices for aquaculture wastewater treatment, can solve the problems of complex components, low removal rate of ammonia nitrogen, unstable operation, etc., and achieve high removal rate , The effect of water discharge is stable and the effect of quick start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

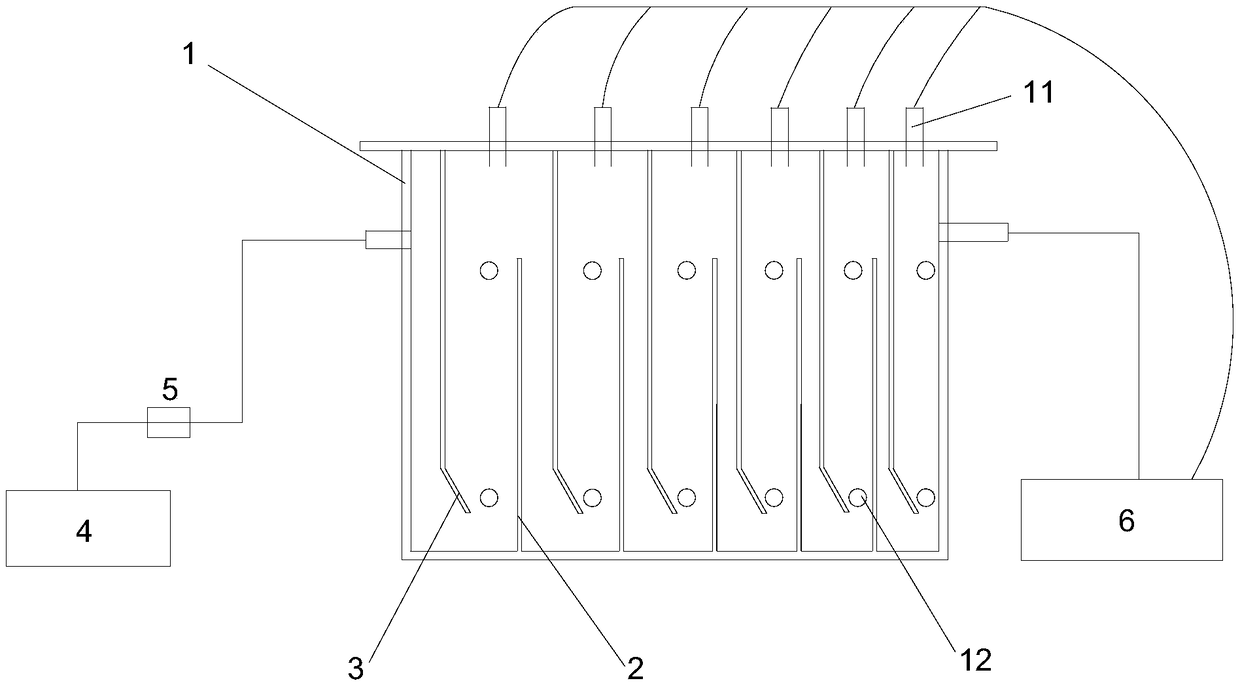

[0032] The ABR anaerobic baffle reaction device for aquaculture wastewater treatment in this embodiment includes an inlet bucket 4, a peristaltic pump 5, an ABR anaerobic baffle reactor 1 and an outlet bucket 6 connected through water pipes in sequence.

[0033] Among them, five partition plates 2 are arranged in the ABR anaerobic baffle reactor 1, and the five partition plates 2 are arranged at intervals and divide the ABR anaerobic baffle reactor 1 into six upper interconnected compartments. , the volume of the six compartments decreases successively along the direction of water flow; each compartment is provided with a deflector 3, and the deflector 3 divides the compartment into two upper flow sub-chambers and a lower flow sub-chamber, the bottom of which is connected to each other. The volume is one-third of the volume of the upper compartment. The lower end of the deflector 3 is provided with an inclination angle of 45°, which plays the role of buffering water flow and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com