Pretreatment method for improving efficiency and stability of culture wastewater treatment by ABR

A breeding wastewater and stability technology, applied in chemical instruments and methods, anaerobic digestion treatment, biological treatment devices, etc., can solve the problems of complex components, low removal rate of ammonia nitrogen, poor wastewater treatment effect, etc., and achieve high removal Rate and water output effect are stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

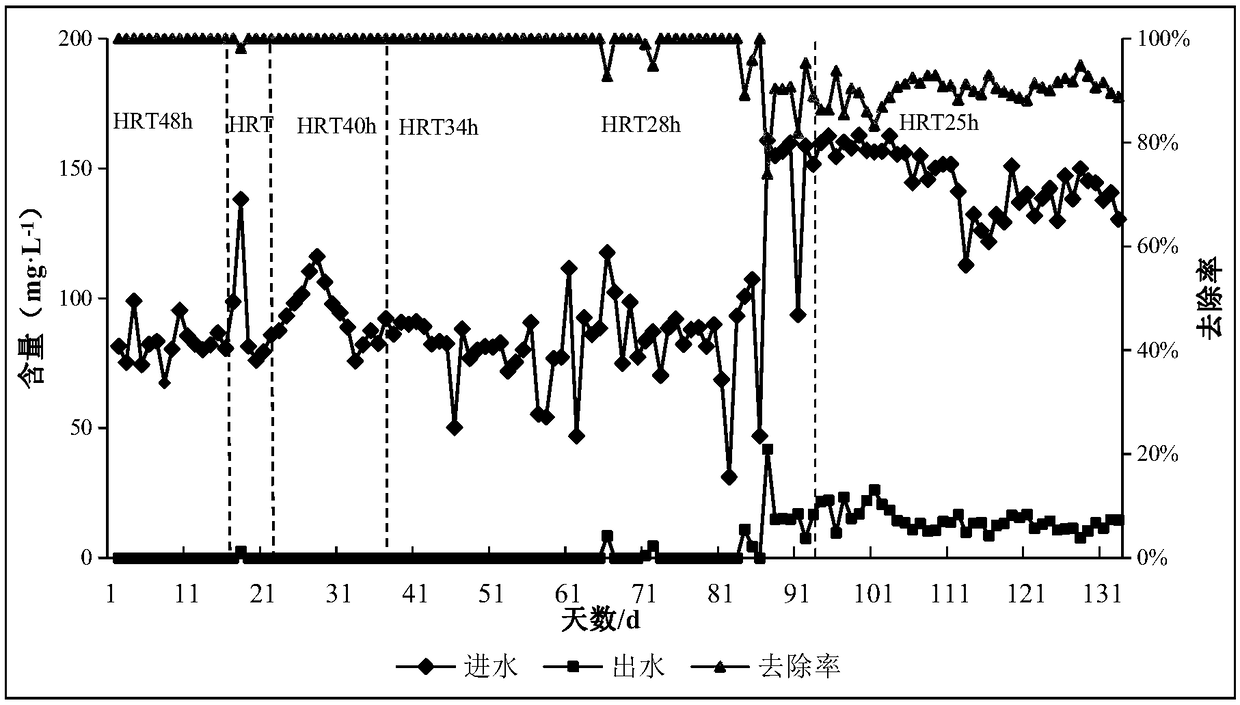

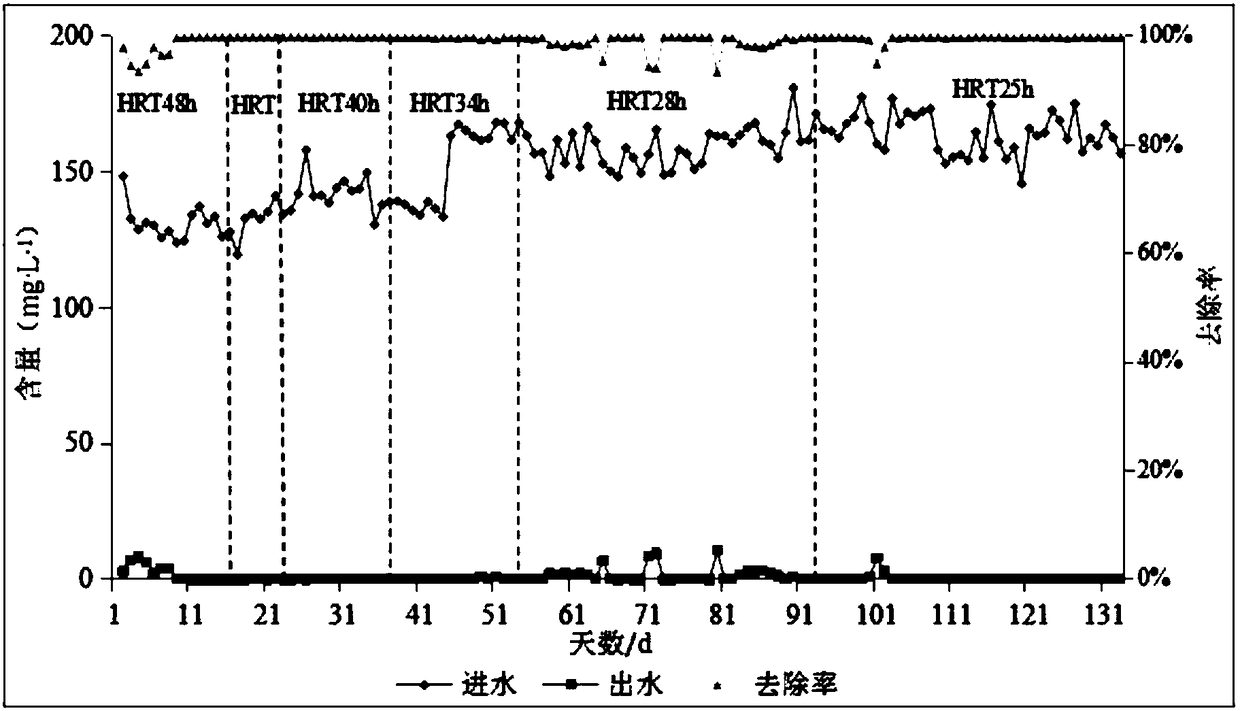

Embodiment 1

[0035] The pretreatment method that the improvement ABR of the present embodiment handles culture wastewater efficiency and stability may further comprise the steps:

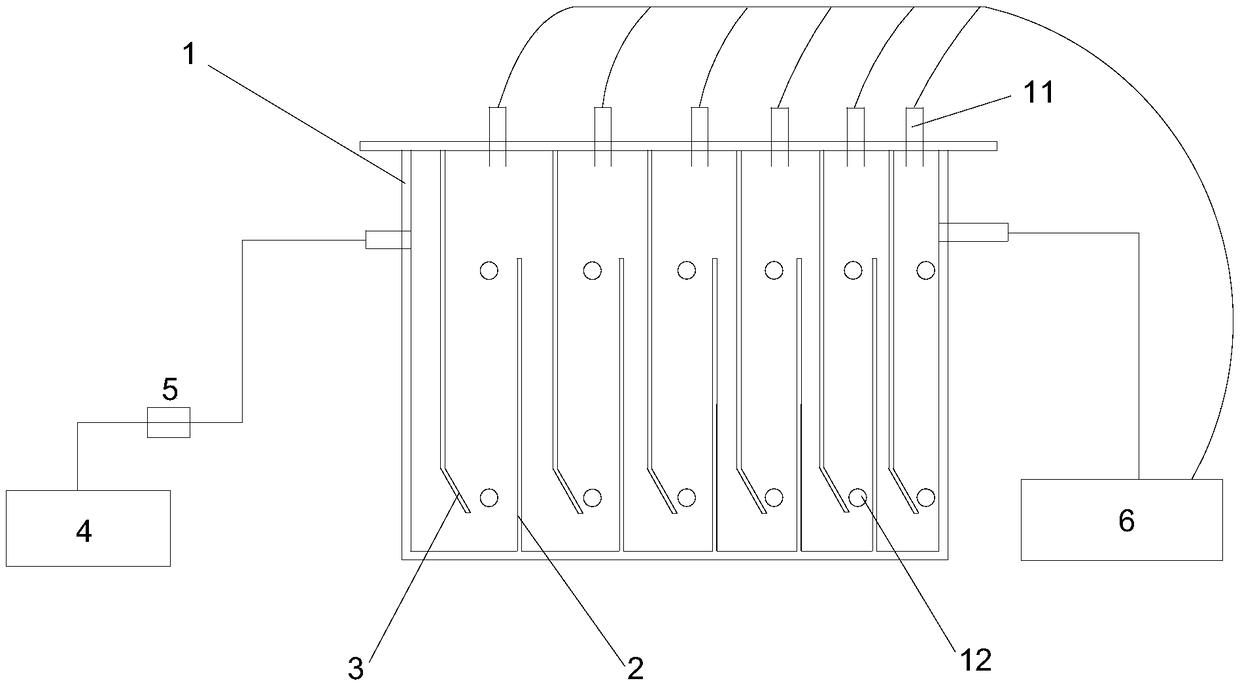

[0036] S1: ABR anaerobic baffle reactor start-up stage

[0037] S1.1: Collection of sludge

[0038] The activated sludge was collected from the sewage treatment plant (Longyan Longjin Water Purification Co., Ltd.), and the sludge was from the activated sludge (not domesticated sludge) of the sewage treatment plant of Longyan Longjin Water Purification Co., Ltd. The level distribution of taxa is as follows: Proteobacteria 48.13%, Chloroflexi 5.26%, Bacteroidetes 13.97%, Acidobacteria 13.74%, Actinobacteria ) 5.72%, Firmicutes 0.35%, Ignavibacteriae 0.42%, Saccharibacteria 6.71%, Chlorobi 1.28%, Gemmatimonadetes ) 1.03%, Planctomycetes 0.01%.

[0039] S1.2: Synthetic wastewater

[0040] The components and concentrations in the synthetic wastewater are: NH 4 + -N 26mg / L, NO 2 - -N 26mg / L, NaHCO 3 1250mg / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective volume | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com