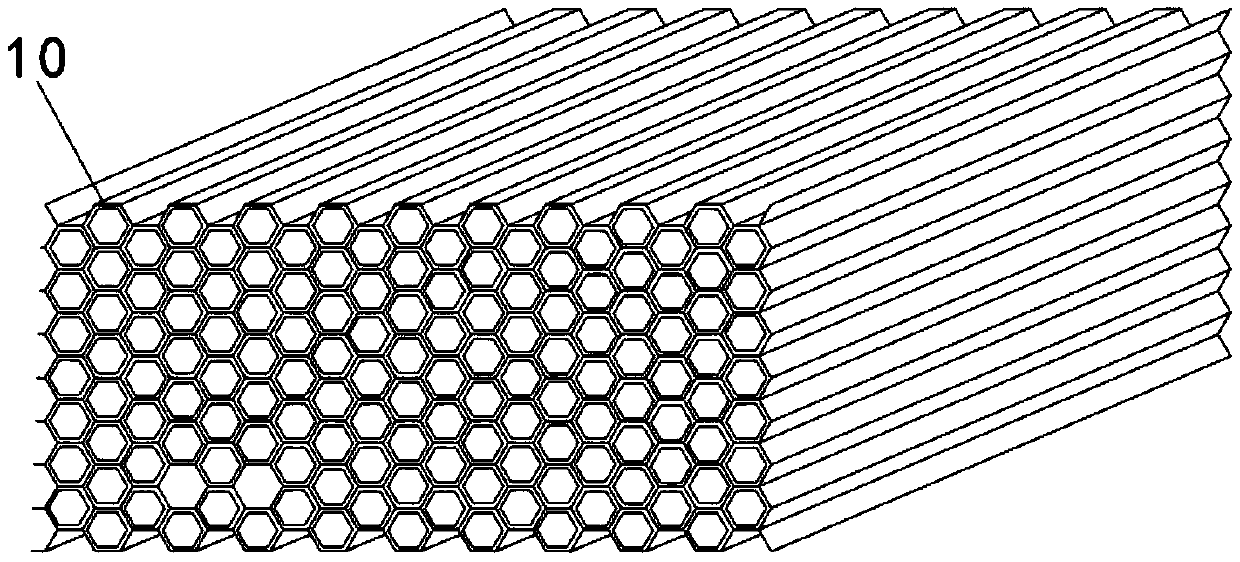

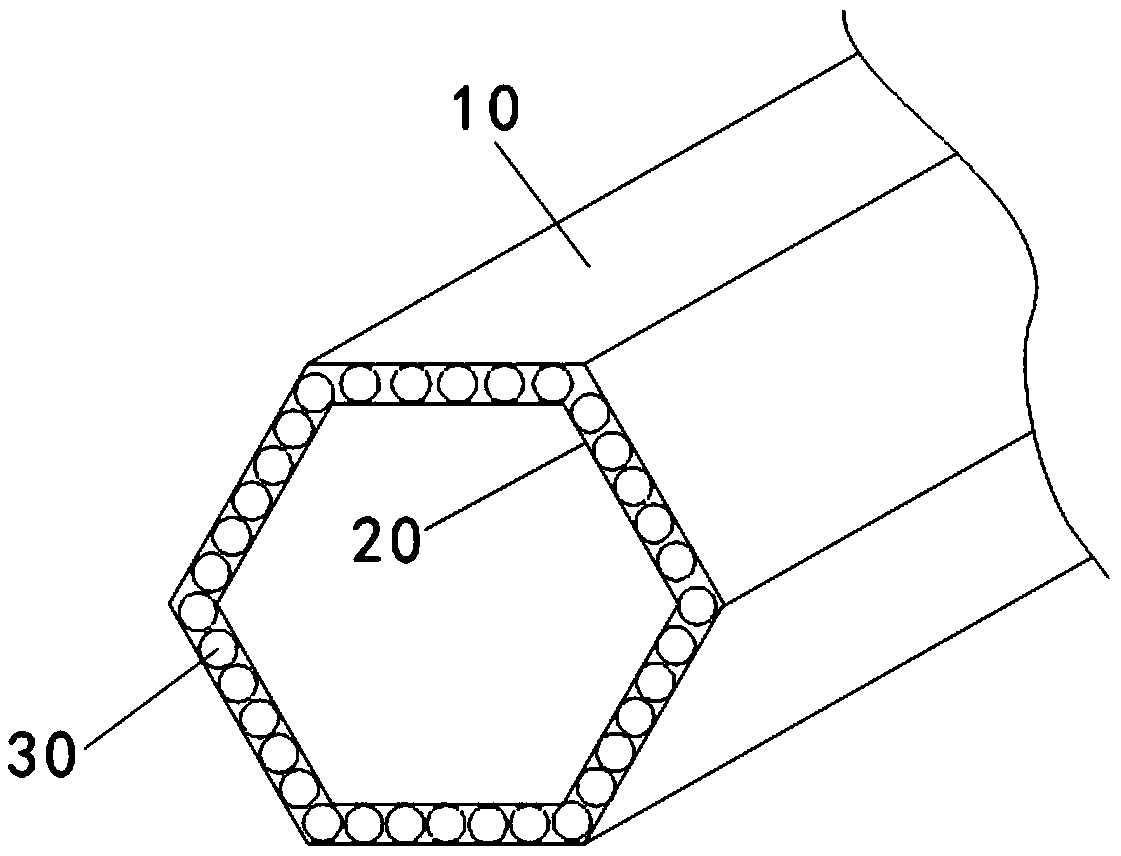

A high-efficiency sewage treatment material and its preparation method

A sewage treatment, high-efficiency technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve environmental damage, affect sewage discharge capacity and other problems, achieve strong adsorption capacity, use The effect of long cycle and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing the high-efficiency sewage treatment material according to any one of the above, comprising the following steps:

[0052] S100, mixing acrylamide resin, sodium polyacrylate, polyethylene glycol, and ether at 120°C-180°C for 60min-120min to form a mixture M1;

[0053] S200, adding N-methyldiallylamine, graphene and calcium peroxide to the mixture M1 and mixing at 80°C-125°C for 30min-80min to form a mixture M2;

[0054] S300, adding calcium bicarbonate powder to the mixture M2, stirring at a speed of 500r / min, and cooling to 20°C-25°C to form a mixture M3; the addition amount of the calcium hydrogencarbonate powder is 12-15 parts;

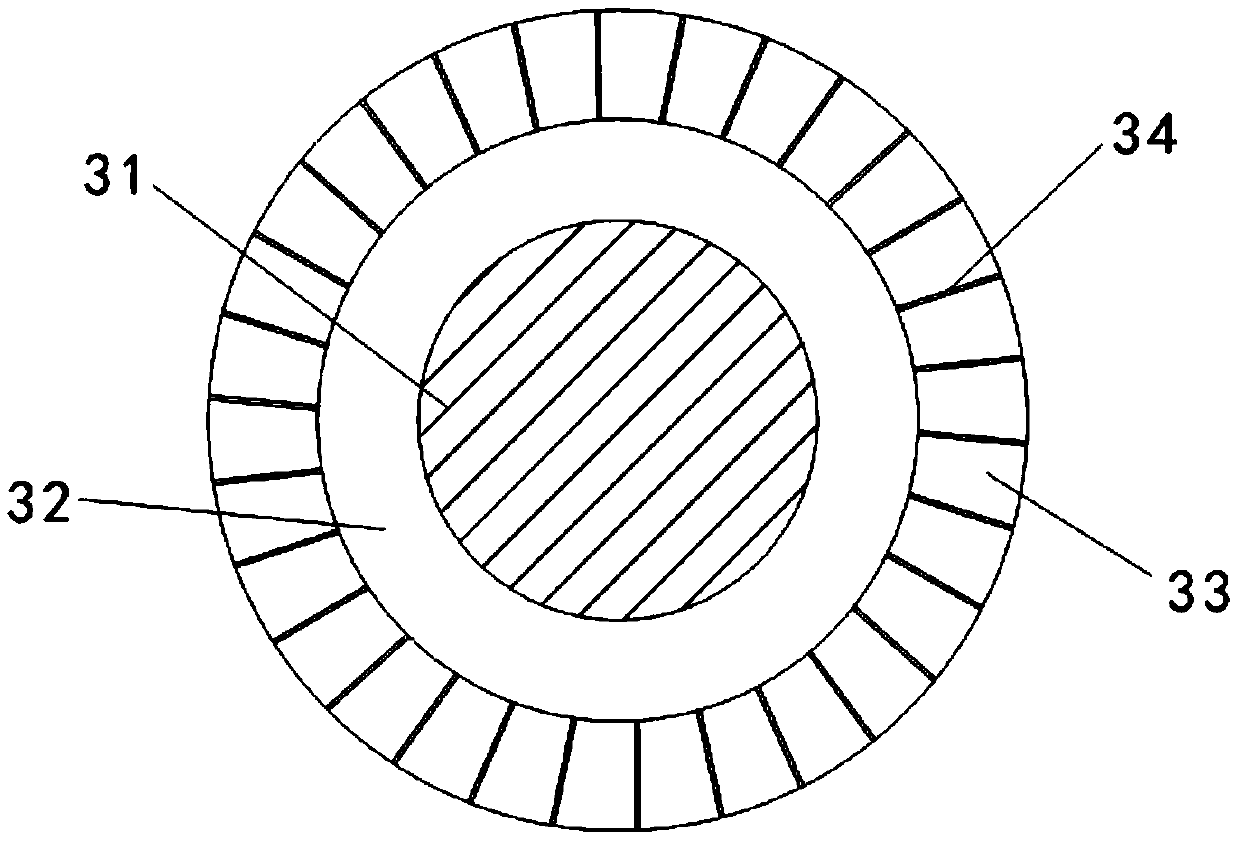

[0055] S400, spray the mixture M3 onto the surface of the activated carbon particles, cool and solidify for 2h-4h, and obtain solid particles S1;

[0056] Mix S500, diatomaceous earth, water, sodium stearate and nitrile rubber at 80°C-95°C for 30min-80min to obtain a mixed slurry M4....

Embodiment 1

[0065] S100. Mix 25 parts of acrylamide resin, 6 parts of sodium polyacrylate, 15 parts of polyethylene glycol, and 20 parts of ether at 150° C. for 80 minutes to form a mixture M1;

[0066] S200. Add 10 parts of N-methyldiallylamine, 2 parts of graphene and 8 parts of calcium peroxide to the mixture M1 and mix at 90° C. for 40 minutes to form a mixture M2;

[0067] S300, adding 12 parts of calcium bicarbonate powder to the mixture M2, stirring at a speed of 500r / min, and cooling to 25°C to form a mixture M3;

[0068] S400, spray the mixture M3 onto the surface of the activated carbon particles, cool and solidify for 2 hours, and obtain solid particles S1;

[0069] S500, 15 parts of diatomaceous earth, 20 parts of water, 8 parts of sodium stearate and 10 parts of nitrile rubber were mixed at 80°C for 50 minutes to obtain a mixed slurry M4. After the solid particles S1 were immersed in the mixed slurry M4, At 120°C, dry and shape to obtain filter spheres;

[0070] S600, arran...

Embodiment 2

[0072] S100. Mix 35 parts of acrylamide resin, 8 parts of sodium polyacrylate, 16 parts of polyethylene glycol, and 22 parts of ether at 160° C. for 90 minutes to form a mixture M1;

[0073] S200. Add 12 parts of N-methyldiallylamine, 3 parts of graphene and 8 parts of calcium peroxide to the mixture M1 and mix at 90° C. for 40 minutes to form a mixture M2;

[0074] S300, adding 14 parts of calcium bicarbonate powder to the mixture M2, stirring at a speed of 500r / min, and cooling to 25°C to form a mixture M3;

[0075] S400, spray the mixture M3 onto the surface of the activated carbon particles, cool and solidify for 2 hours, and obtain solid particles S1;

[0076] S500, 15 parts of diatomaceous earth, 20 parts of water, 8 parts of sodium stearate and 10 parts of nitrile rubber were mixed at 85°C for 60 minutes to obtain a mixed slurry M4. After the solid particles S1 were immersed in the mixed slurry M4, At 140°C, dry and shape to obtain filter spheres;

[0077] S600, arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com