Preparation method of special multi-functional polyester resin

A polyester resin, multi-functional technology, applied in the field of preparation of special multi-functional polyester resin, can solve the problems of complex production process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

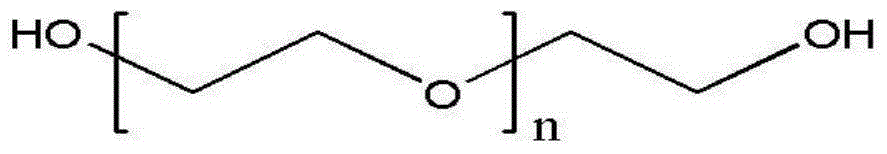

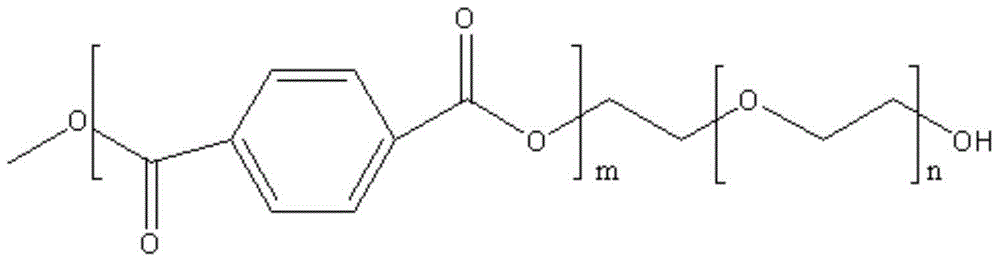

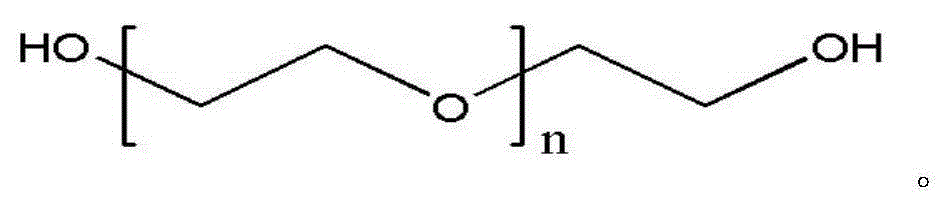

[0014] The principle is to use a reversible esterification reaction to react polyester or modified polyester with polyether polyols of different molecular weights, and carry out molecular rearrangement. The rearrangement polycondensation under vacuum is directly prepared into a multifunctional resin. Modification needs to add self-made intermediates, specifically including the following reaction steps:

[0015] For the preparation of intermediates, add 150g of isophthalic acid, 168 grams of ethylene glycol, and 0.01㎎ of butyl titanate into a 500ml round-bottomed flask, and react at 200°C for 1 hour to form monomer bishydroxyethyl isophthalate ester.

[0016] Next, use 7g of self-made monomer bishydroxyethyl isophthalate, polyester chips (PET) 12g, polyethylene glycol (PEG) 150060g, add a titanium catalyst and react for 2-3 hours under anaerobic conditions at 270 degrees In the later stage, the EG generated by the reaction is evaporated under the vacuum condition gradually inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com