Oven temperature control system for coking oven

A control system and coking furnace technology, used in coke ovens, furnace safety devices, petroleum industry, etc., can solve the problems of high labor intensity, fluctuations in product quality, and high product rejection rate, reduce technical level differences, and solve labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

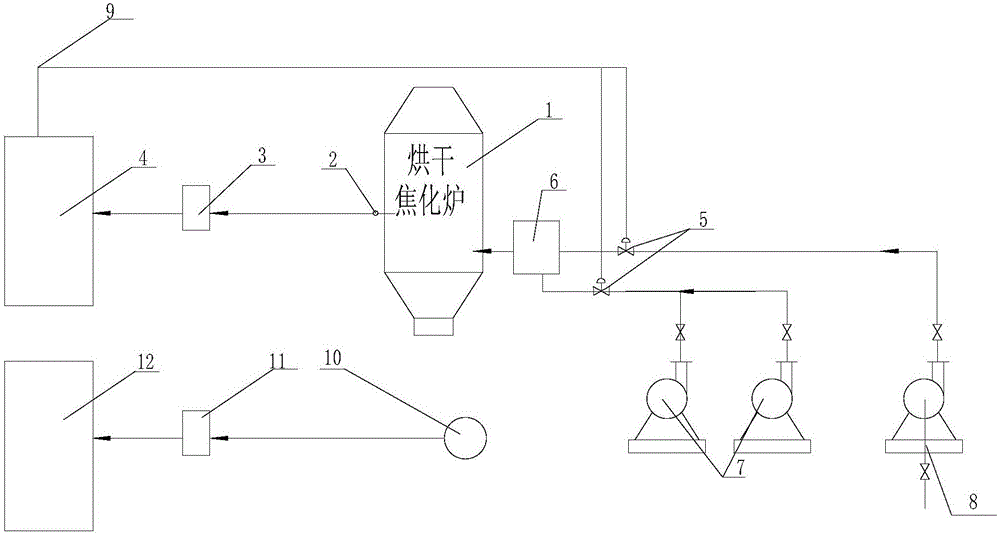

[0017] Embodiment 1: A coking oven temperature control system, including a drying coking oven 1, and also includes a temperature acquisition device 2, a control device 4, an automatic adjustment valve 5, a mixer 6, a mixer blower 7, and a coke oven gas blower 8 , wherein the drying coking furnace 1 is provided with a temperature acquisition device 2, the temperature acquisition device 2 is connected to the control device 4 through the temperature centralized transmission device 3, the control device 4 is connected to the automatic adjustment valve 5, and the automatic adjustment valve 5 is respectively arranged in the mixer The blower 7 and the coke oven gas blower 8 are connected to the mixer 6 , and the mixer 6 is connected to the drying coking oven 1 .

Embodiment 2

[0018] Embodiment 2: A coking oven temperature control system, including a drying coking oven 1, and also includes a temperature acquisition device 2, a control device 4, an automatic adjustment valve 5, a mixer 6, a mixer blower 7, and a coke oven gas blower 8 , wherein the drying coking furnace 1 is provided with a temperature acquisition device 2, the temperature acquisition device 2 is connected to the control device 4 through the temperature centralized transmission device 3, the control device 4 is connected to the automatic adjustment valve 5, and the automatic adjustment valve 5 is respectively arranged in the mixer The blower 7 and the coke oven gas blower 8 are connected to the mixer 6 , and the mixer 6 is connected to the drying coking oven 1 . The coking furnace temperature control system also includes a video acquisition device 10 , a video transmission device 11 and a video display terminal 12 , and the video acquisition device 10 is connected to the video display...

Embodiment 3

[0019] Embodiment 3: A coking oven temperature control system, including a drying coking oven 1, and also includes a temperature acquisition device 2, a control device 4, an automatic adjustment valve 5, a mixer 6, a mixer blower 7, and a coke oven gas blower 8 , wherein the drying coking furnace 1 is provided with a temperature acquisition device 2, the temperature acquisition device 2 is connected to the control device 4 through the temperature centralized transmission device 3, the control device 4 is connected to the automatic adjustment valve 5, and the automatic adjustment valve 5 is respectively arranged in the mixer The blower 7 and the coke oven gas blower 8 are connected to the mixer 6 , and the mixer 6 is connected to the drying coking oven 1 . The coking furnace temperature control system also includes a video acquisition device 10 , a video transmission device 11 and a video display terminal 12 , and the video acquisition device 10 is connected to the video display...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com