A low-quality coal pyrolysis device

A low-quality coal pyrolysis technology, applied in special forms of dry distillation, petroleum industry, coke oven, etc., can solve complex internal heating mechanism and distribution mechanism, difficult to solve temperature control and adjustment, heating temperature uncertainty and other problems, to achieve The effect of solving major losses, continuous and reliable production operation, and improving system reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

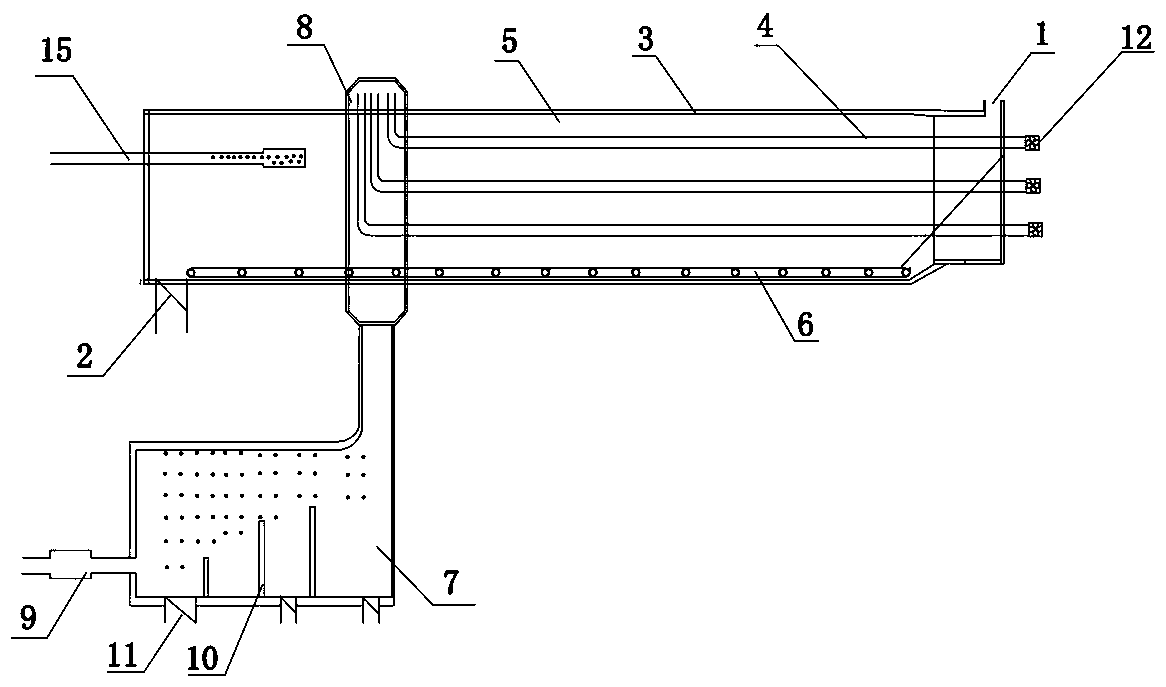

[0024] Such as figure 1 As shown, the present invention includes a closed kiln body 3 with a feed port 1 and a discharge port 2, the closed kiln body 3 is a fixed kiln body, and a plurality of high-temperature gas pipelines 4 are arranged in the fixed kiln body, and a plurality of high-temperature gas pipelines 4 Evenly arranged along the circumference of the fixed kiln body, one end of each high-temperature gas pipeline 4 extending out of the fixed kiln body has an exhaust fan 12, and the inferior coal formed between the multiple high-temperature gas pipelines 4 and the inner wall of the fixed kiln promotes the decomposition channel 5. A low-quality coal propulsion mechanism 6 is set in the low-quality coal propulsion and decomposition channel 5, and the low-quality coal propulsion mechanism 6 is a horizontal crawler. The closed kiln body 3 is provided with a decomposition gas collection pipe 15 connected with the low-quality coal propulsion and decomposition channel 5 for col...

Embodiment 2

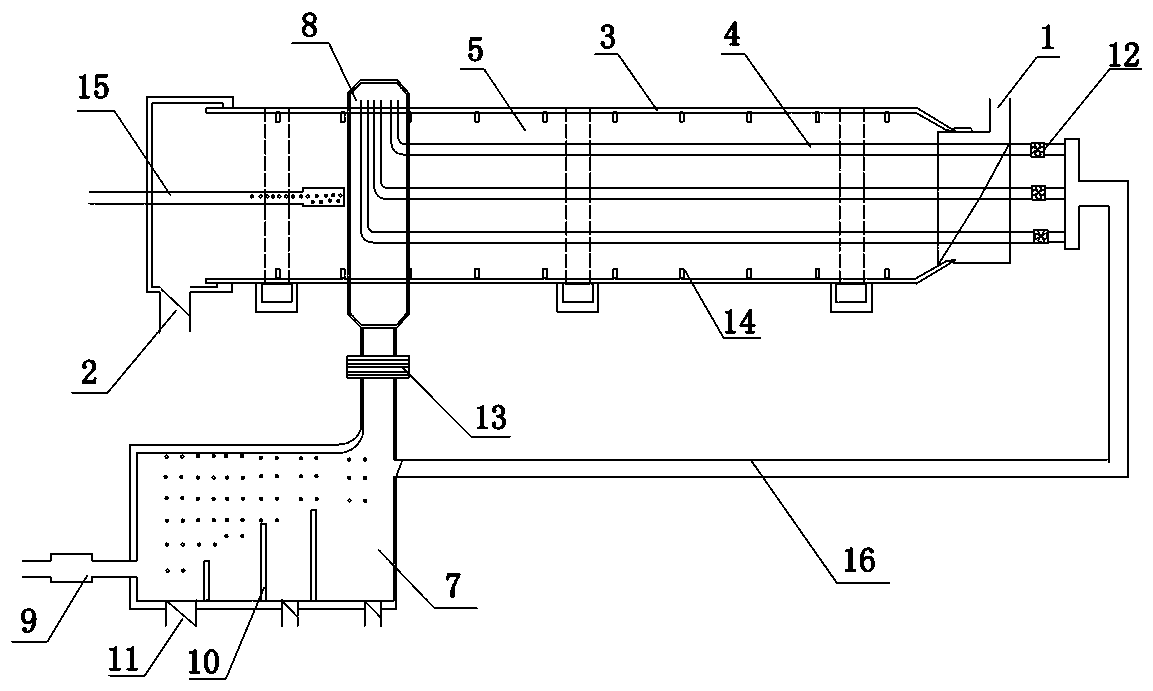

[0027] Such as figure 2 As shown, the present invention includes a closed kiln body 3 with a feed port 1 and a discharge port 2, the closed kiln body 3 is a rotary kiln body, and a high-temperature gas pipeline 4 is arranged in the rotary kiln body, and the high-temperature gas pipeline 4 is a plurality of , uniformly arranged along the circumference of the rotary kiln body, the high-temperature gas pipeline 4 extending out of the rotary kiln body is fixedly connected with a waste gas pipeline 16 controlled by a one-way valve, and each high-temperature gas pipeline 4 protrudes from one end of the rotary kiln body. The exhaust fan 12, the low-quality coal formed between the high-temperature gas pipeline 4 and the inner wall of the rotary kiln advances the decomposition channel 5, and the surface of the high-temperature gas pipeline 4 is provided with a cooling plate 13, which is used to increase the rate of heat dissipation, and the low-quality coal is pushed into the decomposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com