Method for preventing landslides induced by inappropriate liquid injection intensity in in-situ leaching mining

An in-situ leaching and landslide technology, which is applied in the direction of improving process efficiency, can solve the problems of non-ionic rare earth extraction and landslides, and achieve the effect of avoiding waste and increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

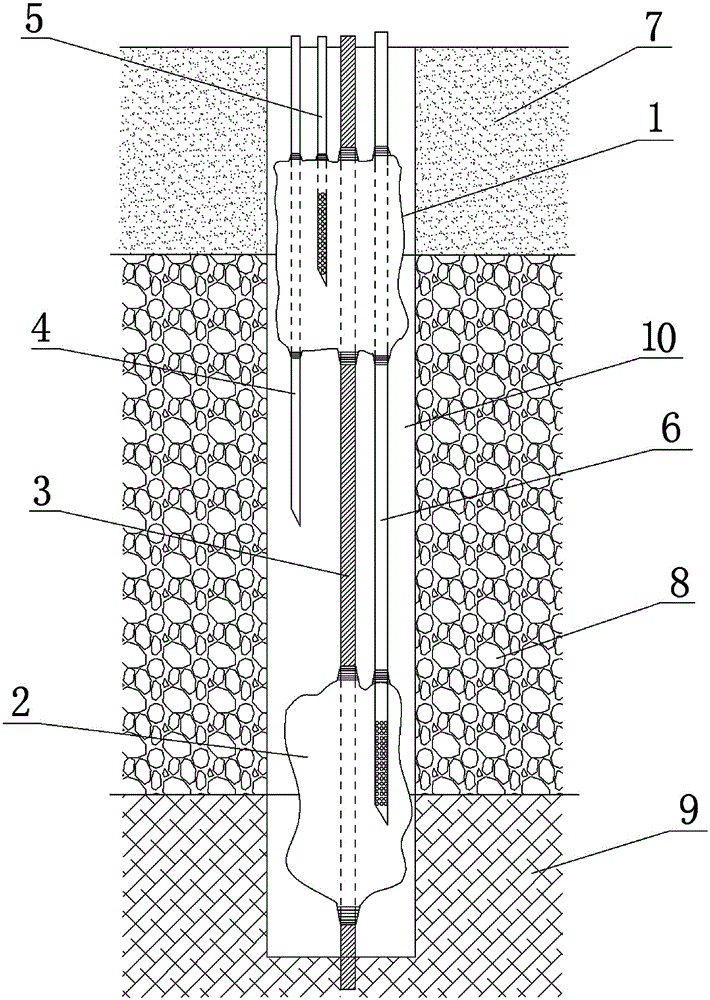

[0016] Such as figure 1 As shown, a method to prevent landslides caused by improper injection strength in in-situ leaching mining, it uses a liquid injection device to inject chemicals for extracting ionic rare earths into the ore body, the liquid injection device consists of the upper layer The mold bag 1, the lower layer mold bag 2, the anchor rod 3, the liquid injection pipe 4, the grouting pipe I5 and the grouting pipe II6, the upper layer mold bag 1 is set on the upper end of the anchor rod 3, and the lower layer mold bag 2 is set on the The lower end of the anchor rod 3, the grouting pipe I5 is inserted into the upper mold bag 1 from the top of the upper mold bag 1, and the cylinder surface of the grouting pipe I5 is provided with a plurality of grouting holes communicating with the inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com